Have you ever wanted to add a belt drive to your bike then realized that you would have to chop your frame to do it? Now a group of creative engineers has a solution. Instead of splitting the bicycle's frame to slip a drive belt through the rear triangle, the Veer belt drive does the splitting, then reconnects with rivets.

Why belt drive

Proponents claims that benefits of a belt-driven bicycle over a chain include increased longevity, less maintenance and a smooth, quiet ride. Another benefit is the lack of grease or oil for a cleaner ride.

Belts and rivets

Unlike a chain that can be sized by removing links, Veer custom cuts its belts to length. Joining the belt on your bike requires around 20 rivets that are cinched down with the included tool.

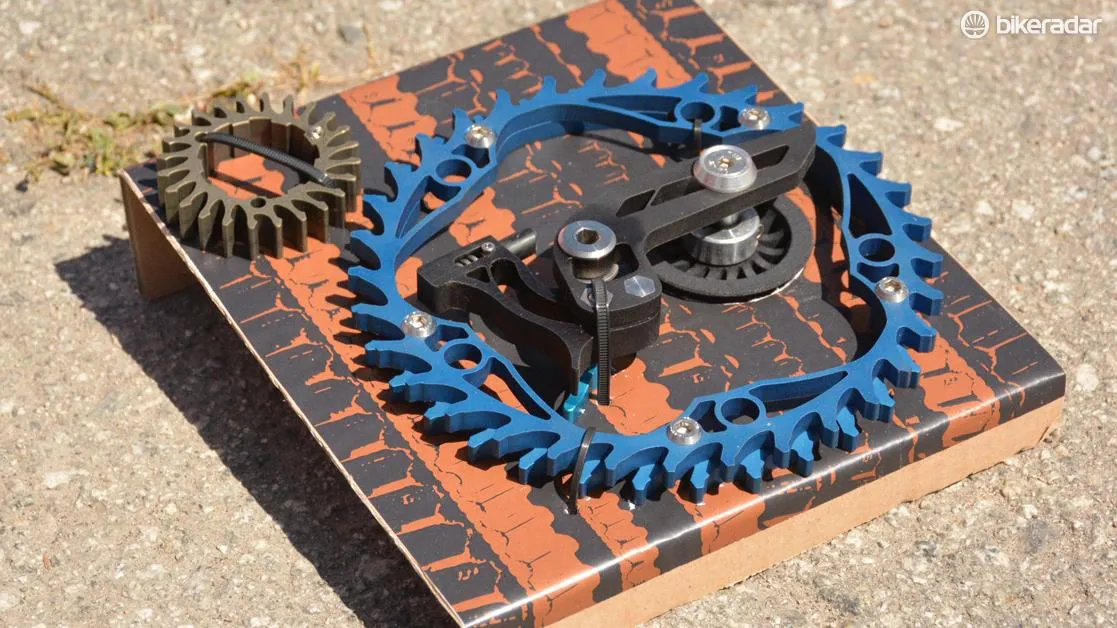

Split Belt M1

Veer's first offering is the Split Belt M1 package. It includes a belt, front cog, rear cog and tensioner.

Are carbon belt drives the future?

The current front belt ring is for use with 5-bolt, 130 BCD crankarm spiders. Veer noted its upcoming Pro version will have more crankarm options in the fall.

The rear sprocket slips on standard Shimano splined freehubs. An ingenious set screw with a roller ball snugs the belt-compatible sprocket to the hub splines. Because of the set screw, alignment is easy and doesn't require spacers.

Current gearing is a 66-tooth ring and a 24-tooth sprocket, which is equal to 42/15.

The $350 M1 system is available now on Veer's website.