Say you're a wealthy Swiss cycling enthusiast who just bought an incredible custom Crumpton road bike – you would, of course, want to take it with you on business trips. When just such a customer approached Arizona retailer Fairwheel Bikes for a custom travel case, they developed one in carbon fibre. For $50,000.

"The case and bike were made for an awesome guy from Switzerland named Olivier," said Fairwheel principal Jason Woznick. "A few years back he saw our world's lightest bike on the internet and decided he wanted to do a project build with us. Being 6ft 2in and 210lb he obviously didn't fit the mold for a standard lightweight build, so we talked to a bunch of manufacturers and had virtually every piece on the bike custom made for him."

A custom carbon travel case for a custom carbon bike

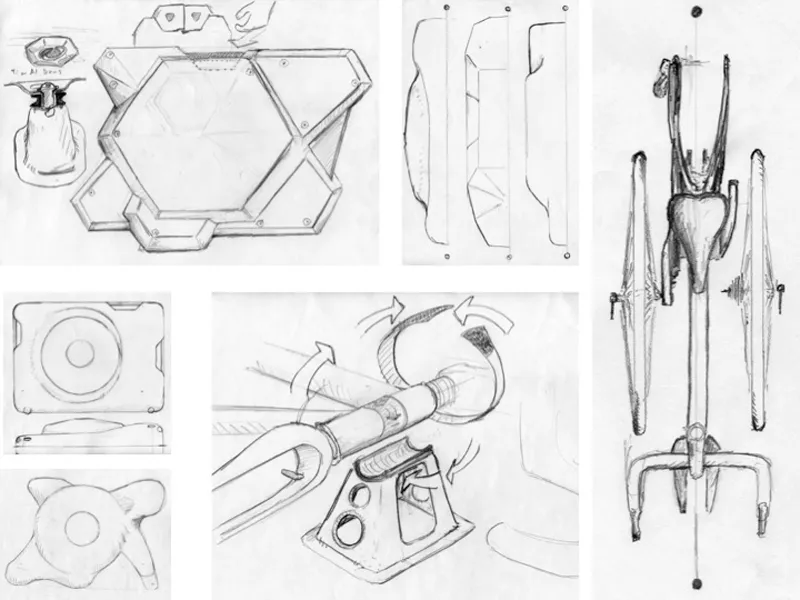

The case is fully bespoke, with a carbon fiber clamshell molded for Fairwheel by Jason Economou at Carbotron Composites. Sturdy grab handles are directly molded into the shape of the case, all of the aluminum pieces are anodized to match the custom anodized bits on the bike, and the whole assembly rolls on "prototype" 360-degree casters.

"We had talked to several people about constructing it and everyone either passed, saying the project was too involved, or they just didn’t possess the excitement we were looking for," said Woznick.

"Jason was sure he could not only deliver what we were looking for but could also meet the aesthetic requirement. It certainly helped that he is a cyclist and had a real passion for this project. He flew out here to work with us on the design process and then returned to his shop to do the CAD modeling and the fabrication (which took about two full years from start to finish). I have to say, he really put himself into this project and did an amazing job."

Much of the magic of the case is on the inside, though. Intriguingly, there's virtually no padding – an almost certain death sentence for conventional cases. Instead, there's a custom cradle that suspends the bike securely in the middle of the case, effectively creating a buffer zone on all sides in case of impact.

Wheels are strapped to the sides of the case in pre-formed recesses, and there are even dedicated spots for two water bottles so they don't jostle around in transit.

The custom design means there's no need for padding

Even better, the cradle quickly pivots outward to create an instant workstand that uses the case itself as a base. Simply undo the custom modified Tune quick-release skewers, leverage the bike up, install the wheels, and you're ready to ride. In fact, you don't even have to straighten out the bar as there's plenty of room for it to just pivot off to the side.

"The bike does not contact the case at all except where it's clamped into the repair stand, which folds down into the case holding the bike so that it does not contact anything," said Woznick. "The stand mount head is well padded so the contact there is no worry.

"The wheels contact the case only in three points, where they are strapped, and each point is well padded. The design was based around minimal disassembly of the bike, since that increases the chances of over-torquing a piece and damaging it."

Okay, so it's hyper-engineered and definitely over the top. But how durable is it? Woznick said the case should be more than capable of handling whatever airport baggage handlers can dish out.

"Structurally, this thing is bombproof," Woznick insisted. Given the investment, it had better be. "The carbon is several millimeters thick and could withstand just about anything. However, I'm sure it's going to get banged up pretty bad. It's probably not going to look as good once it's made a couple of trips to Switzerland and back on commercial flights."

Well-heeled cycling enthusiasts with a penchant for travel probably shouldn't rush to the phone to place an order, though, as there are no plans to bring the creation to market. Woznick said the project cost just over US$50,000 when all the time, materials, and labor were factored in – and that's supposedly with no profit earned.

Very little effort is required to disassemble and reassemble the bike

"The ultimate goal was pretty simple: [Olivier] wanted something unique and something beautiful to share with the world," said Woznick. "The hope is that this inspires and stimulates actual production products based off of these concepts and designs.

"We have no intention to produce another one of these, though we could. The hope is that someone takes the idea in whole or in part and runs with it. In fact, I've already taken an idea from this and am looking at doing this concept on a smaller but no less detailed scale for a Breakaway frame. I’m hoping to start on that project next year using a Holland Jet Breakaway as the bike. A smaller version could be produced more affordably though still would be fairly expensive."