Carbon tubular road wheels we've tested in the past have always presented some sort of compromise. If they're super-light, they're sometimes fragile; if they're very aero, they're often a handful in crosswinds; and if they're tough, they typically ride like bricks.

Zipp's latest 303, on the other hand, manages to tick all the right boxes simultaneously, and if we had to choose one carbon tubular for all situations, this would be it. Try as we might, we couldn’t find any significant faults in our test wheels, just lots of areas in which they excelled.

First off, they're wonderfully light, with an actual weight of just 1,152g for the pair (510g front, 642g rear, plus 120g for skewers) – comparable to even all-carbon (the Zipps' hubs are alloy) wheelsets of similar dimensions, which are also typically far more expensive.

The Zipps are helped along by the company's latest 88 and 188 (as in grams) front and rear hubs but it's the 344g claimed rim weight that really helps the 303s spin up so quickly whenever we were accelerating on the flats and yet we wouldn't hesitate to grab these for an uphill time trial, either.

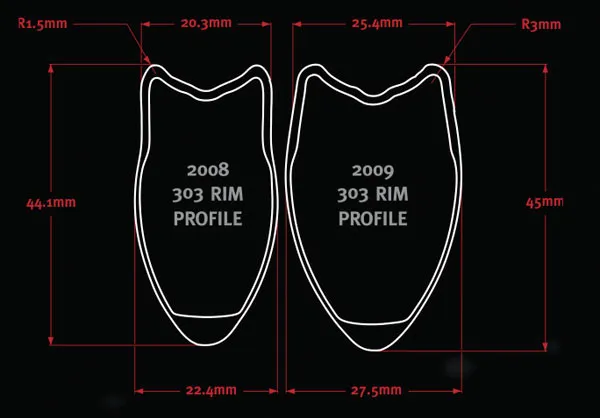

While we weren't able to verify this, Zipp claim that the 303's new fully toroidal cross-section (the brake track is now angled rather than parallel) and uniquely bulged profile records nearly identical drag numbers to its own deeper – and heavier – 404.

That the 303s feel faster and more easily maintain their pace than non-aero wheels shouldn't come as a surprise then. What really impressed us, however, was the 303s' handling manners in crosswinds.

We headed out on one ride in particular with steady crosswinds out of the mountains of over 32km/h (20mph) and swirling gusts of over 48km/h (30mph) – and yet our lightweight test rig remained reassuringly manageable throughout and required far less steering correction than we've experienced with other aero rims in those conditions.

To further prove the point, we hit a top speed of 85.1km/h (52.9mph) on the sinuous descent back into town that day under the same conditions – not something we'd do on a less predictable set of wheels.

The excellent crosswind performance suggests to us that these wheels will maintain their slippery aerodynamics at higher yaw angles where deeper wheels often stall out – a further nod to their versatility.

Torture chamber

Finally there's the toughness aspect. There is no more stringent proving ground for a road wheel than Paris-Roubaix's notoriously brutal Arenberg forest, and this year Zipp-sponsored Saxo Bank star Fabian Cancellara became the first to take the win on carbon wheels.

Like the cobbles, the path there was anything but smooth. "Our first trip to the Arenberg forest was four years ago. I think we took 20 wheels and the team were able to break every single one of them. It literally took minutes," said Zipp technical director Josh Poertner. "We took competitor wheels, too, and the one thing that saved all of our egos was that they broke just as easily."

Zipp's engineers sought to learn as much as they could about the impacts the wheels were being subjected to using still images, high-speed camera footage and lab data, and then redesigned the rims. "We walked the pavé, we took pictures of the pavé, we really tried to learn the pavé," he said. "And everybody agrees that the Arenberg is by far the worst.

"We identified all of the different types of shapes that the wheels hit that are going to break wheels, and we tried to figure out the impact energies for the different shapes and what is happening in that millisecond at the rim. What you're really trying to do is dissipate it either over a larger area or over a larger period of time.

"We spent four weeks doing high-speed camera work studying impact with a sled, learning about all the different types of impacts, the different impact shapes. They all potentially break a wheel differently. It's like a car crash – I can't control the amount of energy coming in, so what can I control?"

The products of that work are Zipp's latest iteration of their Carbon Bridge Technology, which reinforces the rims' outermost edges, and also the 303's exaggeratedly bulged shape. By tuning the flex of the curved sidewalls, Poertner says they were able to integrate a measure of compliance right into the rim – in essence, supplementing the cushion of the tubular tyre with another 'tyre' beneath it made of carbon fibre.

"If you make [the sidewall] bulge a lot as we've done with the 303, it will flare out in a heavy impact," he said. "The spoke bed remains essentially round so that in a heavy impact, you don't get a ton of detensioning in that bottom spoke – the outer diameter is compressing inward and the sidewalls are bulging outward, but the spoke bed is staying essentially the same.

"That is basically buying us time on the order of milliseconds during the impact. So the impact hits, the tyre compresses and bottoms at the rim, but instead of hitting something that's essentially rigid, the whole rim starts to compress locally and the sides flare out and you end up with these extra milliseconds over which that impact is being distributed throughout the structure."

For engineering types, this means that while a graph of force versus time on a standard rim looks like a sharp spike, the 303's graph will have a lower and more rounded peak as well as a slightly broader base. In other words, the area under the curve – and the total amount of energy being dissipated – is the same as before but the stress rate and intensity are sufficiently reduced so that the rim can survive.

That high-speed footage also yielded the large-radius bends at the edges of the rim bed to prevent pinch flats. "The tyre actually ends up wrapping down onto the brake track and instead of seeing a point of contact we've made a little line or patch of contact," Poertner told us. "We made different shapes and literally just kept hitting them with the impact sled." As an extra benefit, the rim sidewalls' tuned flex pattern makes for a distinctly smoother ride, too.

Granted, Zipp's 303 didn't enjoy a perfect track record at this year's Hell of the North – Cancellara did crack one rear rim in the Arenberg. But the other dozen or so 303 wheelsets in use that day reportedly survived unscathed. Plus, Cancellara is a relatively big rider at 80kg (176lb), was running just 94psi over the cobbled landmines, and was able to continue at full speed afterwards (on a still-inflated tyre!) until a better time to swap out equipment presented itself – not exactly a disaster, and everyday riders aren't likely to see those types of so-called 'road' surfaces themselves.

A strategic advantage?

Poertner claims that Cancellara's Saxo Bank team even integrated the 303 wheels into their race strategy for the day. "In some of these flat, windswept areas, [Saxo Bank riders] were seeing a 20+ watt differential from the traditional wheelset to the 303 [during earlier test sessions]," he said. "One of the things they identified was that the wheels extended the range that [the team] thought [Cancellara] could last solo."

As an engineer, Poertner is still realistic, though: Cancellara won Roubaix on 303s but he won the race, not the wheels. "Part of that is just the mental aspect of feeling that you've got that advantage," he said. "Back at Flanders, Cancellara was mano a mano with [Tom] Boonen and he's got this mental image of him riding TT wheels and Boonen is on equipment of the Merckx era. I really want to believe that the physics and math work out and is meaningful in the long run, but so much of this is the mental game."

No sacrifices

That we've found the 303s to be fast, light and stiff – and the pros have proven them to be amply durable – is no small feat on its own but they also make no sacrifices in getting there, as far as we've been able to tell over five months of testing.

In addition to conferring that (nearly) cobble-proof durability, the new rims' 5mm-broader profile makes for more lateral rigidity than before. Combined with the updated hubs' wider and taller spoke flanges, the result is a reassuringly solid platform underneath you, and excellent lateral and torsional stiffness. For more demanding applications like cyclo-cross, Zipp make a front 303 with a higher spoke count as well.

The stock steel hub bearings spin buttery smooth with little seal drag, plus they have easily adjustable bearing preload and their rigidly fixed dust caps don't rattle. Perhaps as a consequence of that low seal drag, though, some pro 'cross riders we spoke to have reported less-than-ideal bearing sealing. However, unless you take a high-pressure washer to your wheels on a near-daily basis, you should be okay – we've had no issues using a standard hose.

Braking performance in the dry is very good with ample power and good control when mated to Zipp's own cork-based Tangente pads (not included). Alloy rims are still better in the wet, though, and the non-parallel sidewalls make for trickier pad setup. The ultra-wide dimensions won't work with some brake callipers and if you're a racer, don’t forget that the 303's non-standard profile will complicate the use of spare wheels, too.

If we really want to nit-pick, the included skewers work okay but their somewhat budget aesthetics aren't suited to the high-end nature of the rest of the wheels. We've already seen an improved set that Zipp have developed with a more svelte appearance and brass rather than nylon cam washers for smoother operation but it might be a while before they're included.

Aside from that, we're totally sold and we're not afraid to admit it. The new Zipp 303 is the best-performing carbon tubular we've tried to date and if you can only have one set of race wheels, this is it.