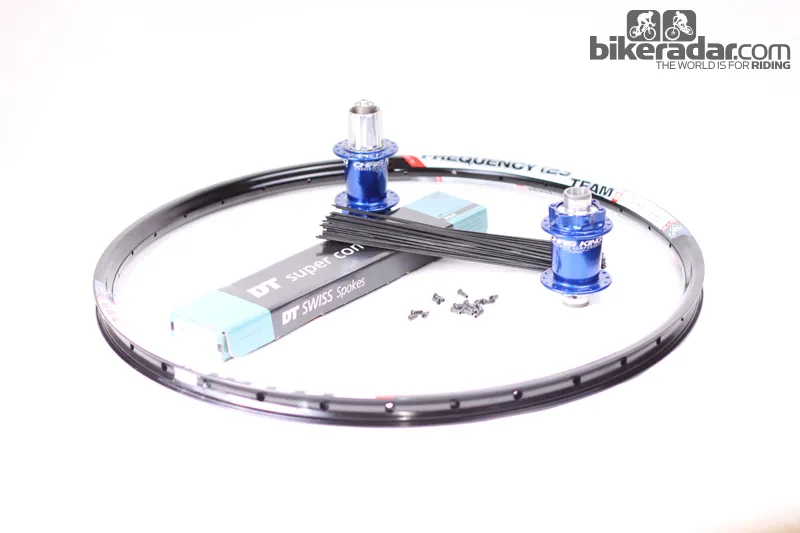

WTB’s Frequency i23 Team rims sparked our interest and gave us the excuse to build a custom all-mountain wheelset of our own. To highlight the new hoops, we picked hubs from American manufacturer Chris King, and spokes from DT Swiss manufactured at the company’s US headquarters in Grand Junction, Colorado.

Even in this day and age of advanced pre-built wheels, there’s no better way to get the wheelset you want than to pick the components yourself. And there’s no better way to get familiar with those components than to construct the wheelset by hand. By weighing the rims and inspecting them for trueness and ease of building before taking them out on the trail, we learned a lot.

Our finished wheels weighed 852g for the front and 1,000g for the rear, with WTB’s tape ($16) and 7g valve stems ($8). Not super light, but respectable for the rims’ width and robust structure.

The custom wheelset cost US$906 for the rims, hubs, spokes, nipples, tubeless tape and valve stems. Considering the quality of the components, and that $1,000 is the standard price for a top-of-the-line aluminum trail wheelset, we were happy with the outcome.

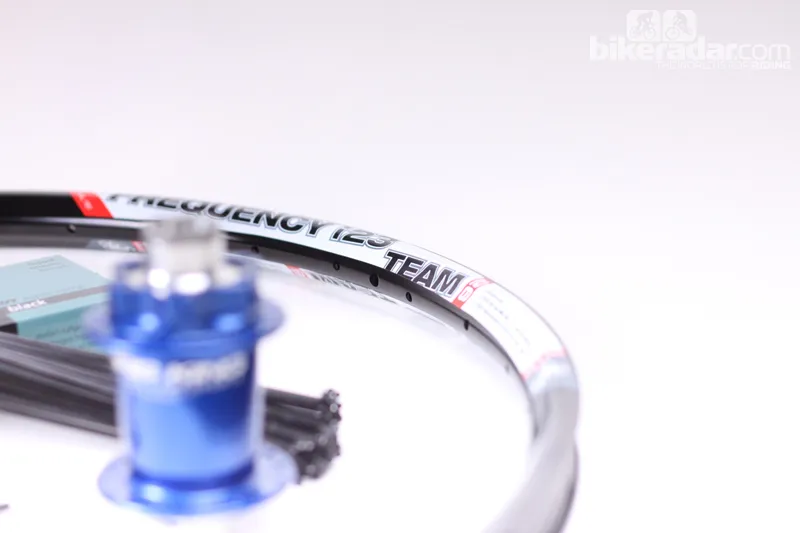

The 23mm rim width makes a noticeable difference to tire profile

Before using this custom wheelset we were riding an acclaimed trail/all-mountain pre-build with a 21mm inner dimension and far fewer spokes. From the first berm it was immediately apparent that our custom set offered more stability to the tire, and a laterally stiffer feel. This was offset by adequate comfort from both the volume of the tires we mounted and the extra give of the three-cross lacing pattern.

Over the course of our two-month test we’ve had to adjust the front hub twice and the rear one once. King actually note a break-in period and adjustment in their owner's manual.

Our wheels have stayed true and round, although we did have one experience that let us know they’re all-mountain wheels rather than downhill hoops. Off a medium-sized drop we cased the transition, flatted the tire and put a good dent in the rim. Pilot error, yes, but the impact also put a decent flat spot in the rim. Back at the shop we checked the tension and put a slight spot true on the wheel. It's run flawlessly since, and we think it could have happened to any wheel.

In all, we’ve been quite happy with our wheelset’s performance, and look forward to riding them long term to see if we need the five-year warranty.

The story behind our custom build

A week after we put in our request to Chris King for their ISO disc hubs – 20mm front (210g) and 12x142mm rear (320g) – we received an email telling us that they were about to ship from the manufacturer’s factory in Portland, Oregon.

Chris King use US materials and pride themselves on their environmentally conscious production methods and bombproof reliability. The latter is evidenced by the five-year warranty the hubs carry. We picked the ISOs because of this reputation, and while they’re heavier than other hubs we’ve been impressed by their material and build quality.

While the hubs might be an obvious choice for any custom wheelset, the DT Swiss Super Comp spokes are sleepers. The triple-butted stainless spokes are a common choice among DT’s US employees, and while they’re slightly heavier than the premium Revolutions. The latter are also about 20 percent lighter.

However, we chose the Super Comps because we felt they were better suited to our all-mountain application. They’re stiffer, stronger and more resistant to wind-up than thinner spokes. And they do it while maintaining a reasonable weight of about 5g per spoke.

DT Swiss supplied their triple-butted Super Comp spokes and black brass Pro Lock nipples

In keeping with our ‘more is more’ philosophy, we passed up the option of alloy spoke nipples in favor of DT’s Pro Lock brass model. These are pre-treated with a thread lock, and offer better durability and strength than the standard aluminum models. They’re 60 percent heavier, but we went for durability over ultra light weight.

Finally there are the rims, which we've discussed before on BikeRadar. One weighed 442g on our scales, and the other 437g. They were reasonably round and true out of the box. There are a couple of key features to note: one is the width, which is a healthy 23mm. The second is the extruded Bead Lock, a secondary lip on the internal well edge that prevents the tire slipping easily into the well and burping.

The third notable feature is the 4D drilling design, which orients the spoke holes precisely and countersinks them to relieve stress on the nipple. The 26in, $75 rims are extruded from a 6000-series proprietary aluminum that WTB call WT69, and use a pin joint.

The inner rim profile uses a shoulder-oriented Bead Lock to prevent burps

We laced the wheels three-cross, and found it slightly challenging to get them perfectly round, although we got there in the end. As wheel-builders know, some rims build up easy and some are harder. We’d put our Frequency i23s somewhere in the middle.