In June, BikeRadar first broke down the details on Shimano's new electric/hydraulic levers, which weigh in at 255g each and which can be paired with hydraulic brakes (468g) and a Di2 drivetrain – at Interbike's Outdoor Demo, we had the chance to ride the system with Ultegra Di2 and were pleasantly surprised.

The levers feel very similar to standard Di2 levers in ergonomics and braking performance — but with less hand force required. More recently, we’ve been able to spend a full three days riding them at Shimano’s press camp in Sicily.

See also

- Shimano BR-R785 road hydraulic disc brakes – first look

- Shimano BR-R785 road hydraulic disc brakes: under the hoods

Shimano has just confirmed that the UK pricing for the R785 brake system will be £499.99. We are awaiting details on US pricing. At first blush, we prefer this hydraulic road system to SRAM's.

- Pros: Great ergonomics – identical with Di2 levers; reach and stroke adjustments; brake lever action feels like mechanical – but stronger

- Cons: Tinny, rattling sound when riding with hands on tops (without cables, the lever head has nothing to pull it snug against the hood body); lack of standard Shimano tiered branding (it's not Dura-Ace, it's not Ultegra, so what is it?); dull finish

In detail

There’s still a question of whether or not hydraulic brakes are the way forward, but the main issue that the naysayers have is that there isn’t any real ‘need’ for more powerful braking. Shimano understand this, so the point of these new brakes isn’t improved power but better feel and consistency, regardless of conditions.

Shimano’s hydraulic STI unit is significantly bigger than the standard Di2 and mechanical levers. It seems early rumours that the hydraulic hoods would be the same size were a little optimistic.

The Shimano R785 Di2 STI unit (r) is considerably bigger than a standard mechanical or Di2 shifter

Comparisons between R785 and SRAM’s hydraulic road system are inevitable, and there are a few notable differences between Shimano's hydraulic road system and SRAM's. The most obvious is the lever shape; using electric shifting frees up considerable real estate for the hydraulic internals for Shimano, while SRAM stacks its reservoir on top of a mechanical design, meaning the lever is a little bigger.

Another difference is the strategy and presentation. SRAM launched hydraulic road brakes at the top of its food chain with Red 22 (and also the lower, non-series S-700), while Shimano has begun with only a non-series R785 lever that is neither the top-level Dura-Ace or the second-tier Ultegra. Why? Shimano spokesman David Lawrence said that the company isn't yet satisfied with the product, and feels that improvements in performance, weight and finish must be made before it can be branded Dura-Ace.

In fact, this entire system is still a work in progress – the hubs and calipers are XT mountain models, and the rotors are 160mm, to be reduced to 140mm in the full production versions. Shimano has entered other categories in similar fashion before. Its first compact crank was the R700 – not an Ultegra or a Dura-Ace. And its first hydraulic mountain bike brake was an XT – not the top-of-the-line XTR.

The production versions of the brakes will use 140mm, not 160mm rotors

Ride and handling

We got to experience these brakes first hand over the course of three days. The first day included a 17km descent, and our initial impressions were very similar to our first thoughts on SRAM’s Red brakes. The braking was consistent, there was plenty of feel, but they did have a tendency to screech noisily once we’d built up a bit of rotor heat.

Shimano r785 hydraulic brakes first ride

Video: Shimano BR-R785 hydraulic brake testing, day one. Note: the noise had quietened down considerably by day three.

But by the final day the front disc (which you use more) had become almost silent, although the rear still gave a bit of noisy feedback. We don’t doubt that a few more rides, especially in more challenging conditions (Sicily was consistently warm and dry) this running-in time would be reduced somewhat.

Our findings from testing Red certainly bear out with Shimano too. It’s not about power – it’s about increased control. The key thing to note is that the disc brake doesn’t offer too much power – it offers about the same as the new (and frankly brilliant) Shimano Dual Pivot design (found on the new Dura-Ace and Ultegra). What matters is how you can feed it in.

Getting just enough brake force is an effortless experience; a single finger is all it takes. We took on the same descent on rim brakes and could feel the effort through our hands at the bottom with the standard brakes, but with discs we had no such issues with pumped up forearms. If anything, we’d say that the disc brakes are actually harder to lock up.

The other fear with disc brakes is overheating. Pushing a disc to its limits and boiling the fluid will mean a big loss of power with potentially dire consequences. Like SRAM, Shimano has certainly done its homework. SRAM tested on some of Europe’s toughest descents, and Shimano seems to have been sharing the same roads.

Test riders suited up with diving weights and full body armour to raise the rider weight to 130kg made sure the brakes could handle the extremes. They even tried runs where they dragged the brakes all the way down Mount Elba, maintaining a speed of 15mph for 10km, just to try to cook the brakes. The testing only finished in August this year, that’s why Shimano were reluctant to give us any weights for the system – even at the official launch we were still riding a combination of production and prototype – it’s Shimano’s policy not to release weight details until after the first full-production run.

The highly finned (for cooling) pads are available in either resin or metal bodies

Shimano has combatted heat issues with finned pads that it's appropriated from the mountain side of the company (the pads are packaged with mountain bike groupset logos too, so they are essentially the same), as well as the Ice-Tech Freeza rotors. The rotors have a steel outer on both faces, sandwiched between an alloy. This is because the alloy absorbs heat faster the steel, drawing away heat from the surface to stop it building up too quickly. Shimano claims that this sandwich design reduces heat by 150ºC.

One mildly irritating point is the tinny rattle caused by the lever head vibrating against the body of the hood when riding over rough surfaces with your hands on the tops. When riding on the hoods, your hands absorb the vibration and eliminate the problem. But unweighting the hoods, when road conditions are choppy, results in noticeable noise. The reason for this is that hydraulic road levers (both Shimano and SRAM) by design lack the cable tension inherent in mechanical systems, so there is nothing holding them tautly in place.

In all, our first impressions of Shimano’s discs are good, if not great. The downside is that they are Di2 only, which means it’d be a fairly big investment to get discs now. SRAM may have an advantage here with its non-series 10-speed option sitting alongside Red.

We couldn’t say which system is better without some straight back-to-back testing. Thankfully that shouldn’t be far off – we already have Red in the office ready to be built onto Decade’s classy titanium Tripster ATR, and Shimano will be shipping our test groupset very soon. Once we’ve built that one too, then we’ll get some direct comparisons between the two (and standard brakes).

Pro opinion

Road racer Andy Schleck, guest of honour at Shimano’s press camp, had some positive things to say regarding the disc vs rim debate.

Plenty of people have claimed that pros don’t need or want them. But Andy had a different take: “If you’re descending in the wet, especially on lightweight carbon rims then there is often water on the rim braking surface. That means you need to brake early, to give time to clear that water. In turn, that often means you are dragging the brake into corners with no guarantee of when braking is going to happen.

“On a long descent in hot conditions, they way a brake feels at the top is different to how it feels at the bottom once the rim has become hot. Mostly this results in a ‘grabby’, sudden brake feel.”

Braking feel and adjustability

When braking on the road, the Shimano R785 levers and hydraulic feel similar to Dura-Ace mechanical calipers in terms of the ratio of lever pulled to brake force applied at the wheel. With SRAM's Red 22 Hydro-R system, the levers have to be pulled noticeably more for the same amount of braking. In both cases, the finger force required is less than a mechanical system.

Whether using the brakes to shave off a little speed or to pull up quickly for an abrupt stop, the system engages quickly and predictably, with plenty of throw left at the lever.

The levers can be substantially adjusted for reach and mildly adjusted for free stroke

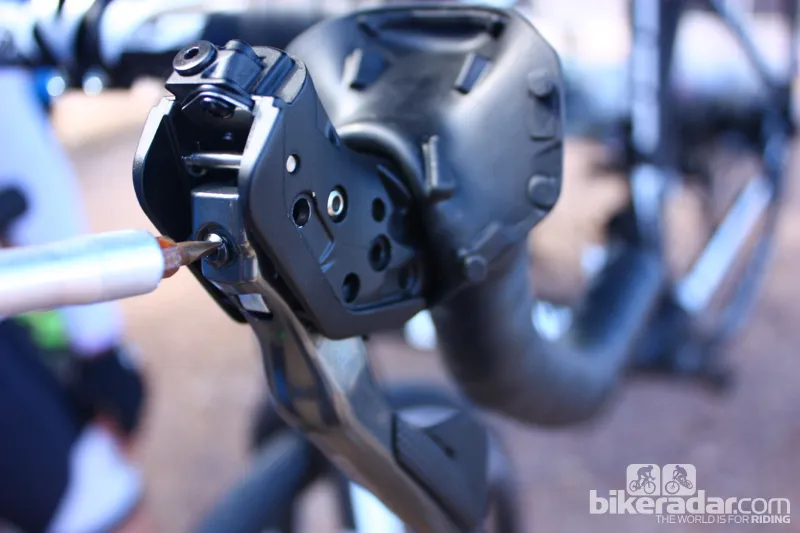

The levers can be adjust for reach (how far the lever sits in neutral position from the handlebar) and what Shimano calls free stroke (the point in the pull of the lever at which the brakes begin to engage). Both adjustments are made with screwdrivers underneath the hood.

The brakes use Shimano's mineral oil, and servicing them is identical in both process and tooling to the company's mountain bike brakes.

Where this will pop up

Are disc brakes the future of road bikes? It's looking that way

As the R785 system is becoming available later this year, cyclocross bikes will be the first to arrive with the product as original equipment. Then road bikes will begin trickling out with Ultegra Di2 and perhaps Dura-Ace Di2 and hydraulic brakes. Its potential adoption for sales as a standalone group, if it comes, will be months, if not years, away.

So are discs the future? On this and SRAM’s evidence we’d suggest they are. Yes, a hydraulic road brake system is heavier than a mechanical rim caliper system. Lawrence claims Shimano's system adds roughly 300g — not including additional potential weight on the frame and the fork. And for the pros, a lot of issues need to be sorted. For the UCI’s there’s the issue of parity across the board – it’d be dangerous for half the peloton to have the massive advantage these brakes offer.

The other issue is standardisation of equipment for neutral service. As mentioned before, our bikes ran 160mm rotors, but Shimano recommend 140s. The problem is that there aren’t that many bikes with post-mount fittings to take the reduced size. Should the road follow mountain and go through-axle? Brands such as Storck, Focus and Giant, with their new CX bike, seem to think so.

With Shimano's rim brakes already quite functional, many riders and even many shop owners are asking what the point is. Shimano, as with SRAM, points to 'consistent braking across all conditions,' and 'better modulation and more power for less finger input.'

It’s worth remembering how long it took mountain bike brakes to evolve to their current high-performance state. They’ve had more than a decade of development – for the road we reckon it’ll be three to five years before we see what disc brakes are capable of. Road bikes have the advantage of the mountain bike designers doing most of the groundwork – now it's a question of adaptation and evolution.

For most of us, the positives will outweigh the negatives. Better, more consistent braking is going to make you faster and safer, and how can that be a bad thing? Ultimately you, the riders, will dictate whether this system truly takes off or if it remains a novelty.