If you thought inner tube development had ground to a halt as the tubeless tyre juggernaut comes screaming through, think again. Schwalbe has developed a plastic inner tube said to offer reduced weight, improved ride quality and increased puncture protection over a conventional butyl or latex tube, while also allowing for the use of lower tyre pressures.

Dubbed Aerothan, the transparent inner tube is made from a thermoplastic polyurethane material said to offer “a high level of resilience, unique ultimate tensile strength, superior damping properties, extreme heat resistance and greatest wear resistance.” Schwalbe also says the inner tube (including the valve) is recyclable.

The Aerothan is available in eights variants, for road riding, gravel/urban/touring and mountain biking. Weights start at 41g for the road tube, for size 23 to 28mm tyres.

Despite the name, it’s worth saying from the outset that the Aerothan tubes obviously have no aerodynamic advantage – the name is a play on the material.

Also, while the tubes look similar to the Tubolito design we’ve featured previously on BikeRadar, Schwalbe says Aerothan has been designed from the ground up.

Anyway, the benefit of Aerothan, Schwalbe says, is in retaining the ease-of-use of an inner tube, while addressing some of the drawbacks of traditional tubes, so let’s take a closer look.

Puncture and heat resistance

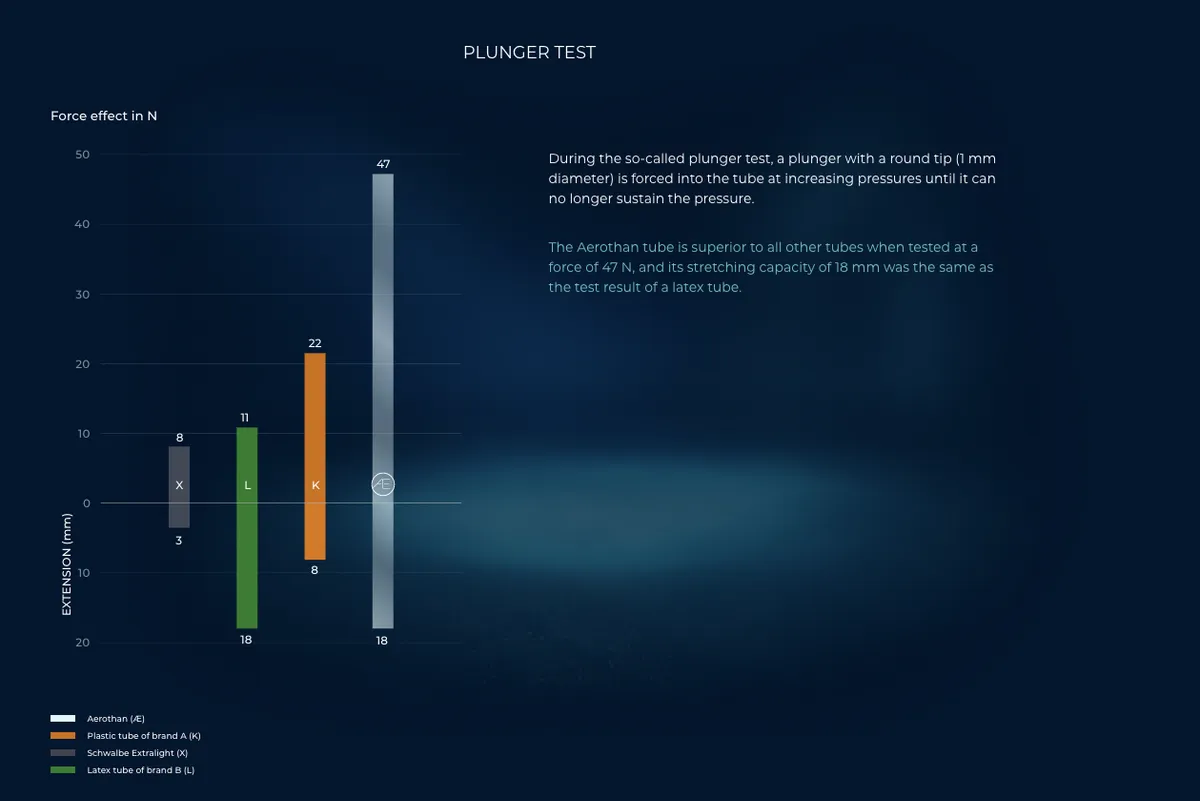

According to Schwalbe’s plunger test, which simulates a small object, such as glass, a flint or a metal shard piercing a tube, 47 newtons is required to puncture the Aerothan material – more than double rival materials tested.

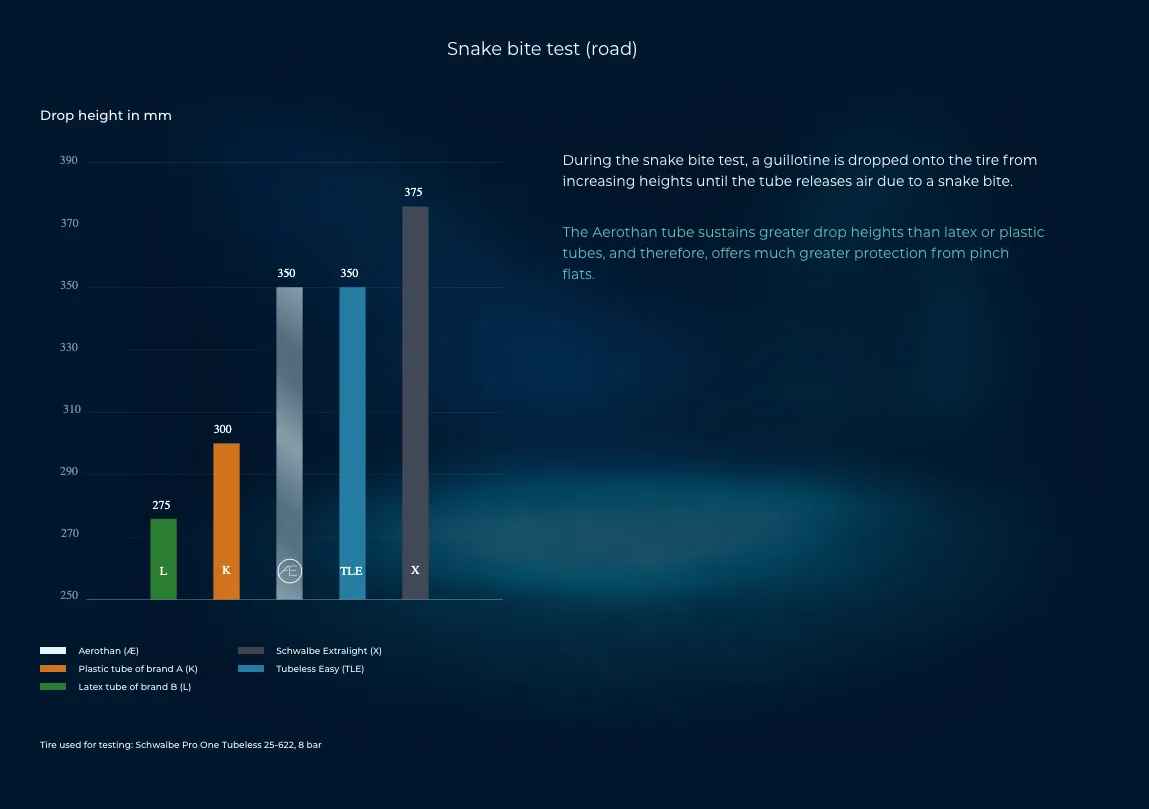

Schwalbe also performed a guillotine test to replicate a snake bite puncture, with Aerothan once again outperforming butyl, latex and other synthetic tubes.

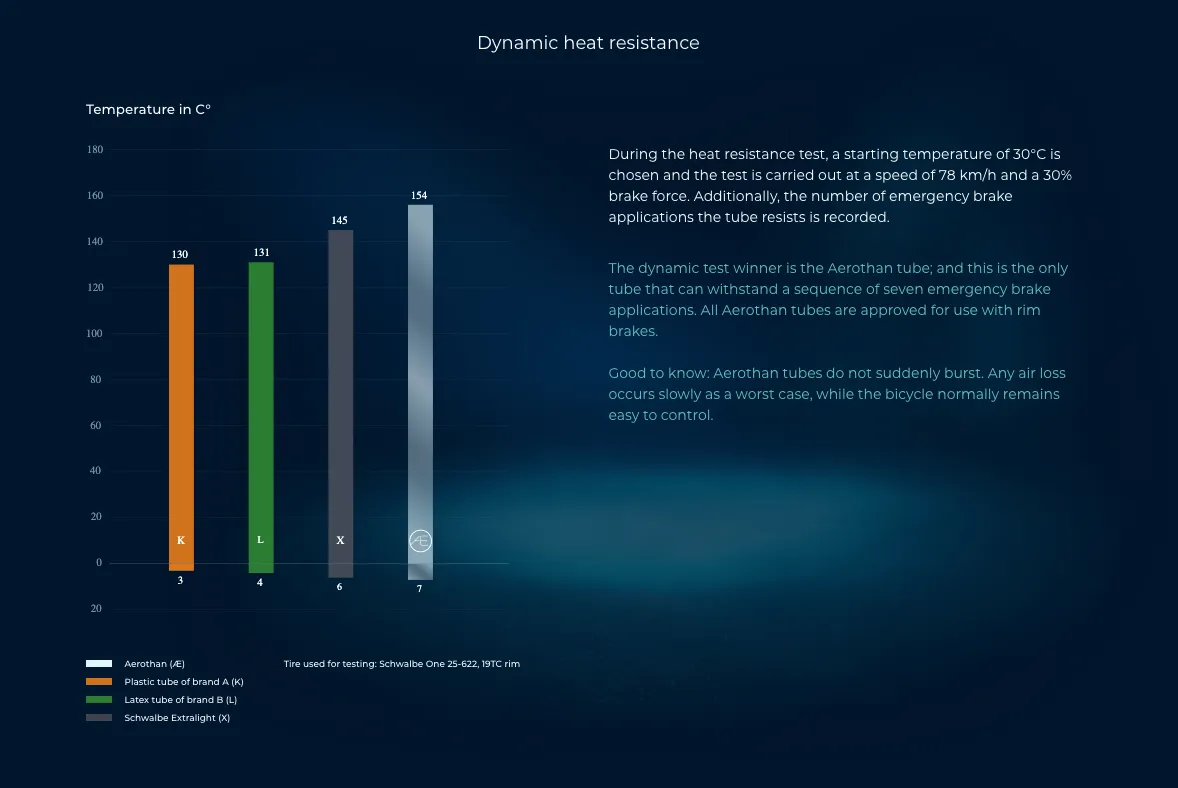

If you ride a rim brake bike and are worried about heat-related tube failures, Schwalbe also says the Aerothan material was tested to more than 150°C at 78 kph.

But what about tubeless?

That's all very well and good, but aren’t tubeless tyres supposed to solve the problem of punctures inflicted by small cuts or snake bikes?

Well, Schwalbe says it’s still firmly backing its tubeless technology across road, gravel and mountain bikes.

No matter what they’re made of, standard inner tubes alone can’t replicate the self-sealing properties of a tubeless setup. Instead, the Aerothan tubes are designed to offer a (pricey) alternative to riders who quite simply prefer using tubes.

“Additionally, certain wheel types are not suitable for tubeless,” reads Schwalbe’s press material. “Therefore, we have developed Aerothan tubes – the high-end alternative to conventional bicycle tubes. Many of its technical advantages achieve the same high standards that tubeless systems do.”

One of those advantages is the ability to run lower pressures, as a result of the additional “stability” of the Aerothan material over butyl or latex, and its resistance to snake bite punctures.

In fact, Schwalbe recommends referring to recommendations for tubeless tyre pressures when using Aerothan tubes.

“Please note that the minimum air pressure engraved on Schwalbe tires applies to the use with butyl tubes,” it adds. “When using Aerothan tubes, lower values may be applied.”

As an aside, Schwalbe says the Aerothan tubes can be repaired with its self-adhesive patches, like a normal tube. Roughening the tube is apparently not necessary; instead, the patch can be applied directly to the tube.

Weights and prices

In terms of weight, Aerothan tubes start at 41g (claimed weight) for road bikes and 61g (claimed weight) for mountain bikes. For comparison, a Schwalbe Extralight butyl tube weighs 65g, so there’s a 24g saving with the equivalent Aerothan road tube.

If you’re running a standard Schwalbe road tube, with a claimed weight of 105g, you could save 69g per tube, or 138g across the bike. Not a huge amount, of course, but not inconsiderable considering the cost required to achieve a similar weight saving on other components.

Schwalbe's Aerothan tubes start at €27.90 (UK and US pricing TBC).

| Wheel size | Tube size | Version | Weight | Price |

|---|---|---|---|---|

| 26" | 54/62-559 | MTB | 81g | € 27.90 |

| 27.5" | 54/62-584 | MTB | 83g | € 27.90 |

| 27.5" | 62/75-584 | MTB+ | 109g | € 27.90 |

| 700c | 23/28-622 | Race | 41g | € 27.90 |

| 700c | 28/35-622 | Race Endurance | 50g | € 29.90 |

| 700c | 37/50-622 | Allround | 61g | € 27.90 |

| 29" | 54/62-622 | MTB | 87g | € 27.90 |

| 29" | 54/62-622 | MTB+ | 116g | € 29.90 |

Air retention

Schwalbe also says the properties of Aerothan mean a tube won't suddenly go flat in the event of a puncture.

“In case of a defect, air escapes only very slowly,” says Schwalbe. “Even at extremely low air pressure, it retains its shape and thus stays rideable in a stable manner – pinch flats or burping becomes much less of a threat. In addition, mounting is much easier. The tube does not slide away and cannot get caught.”

Is it fast?

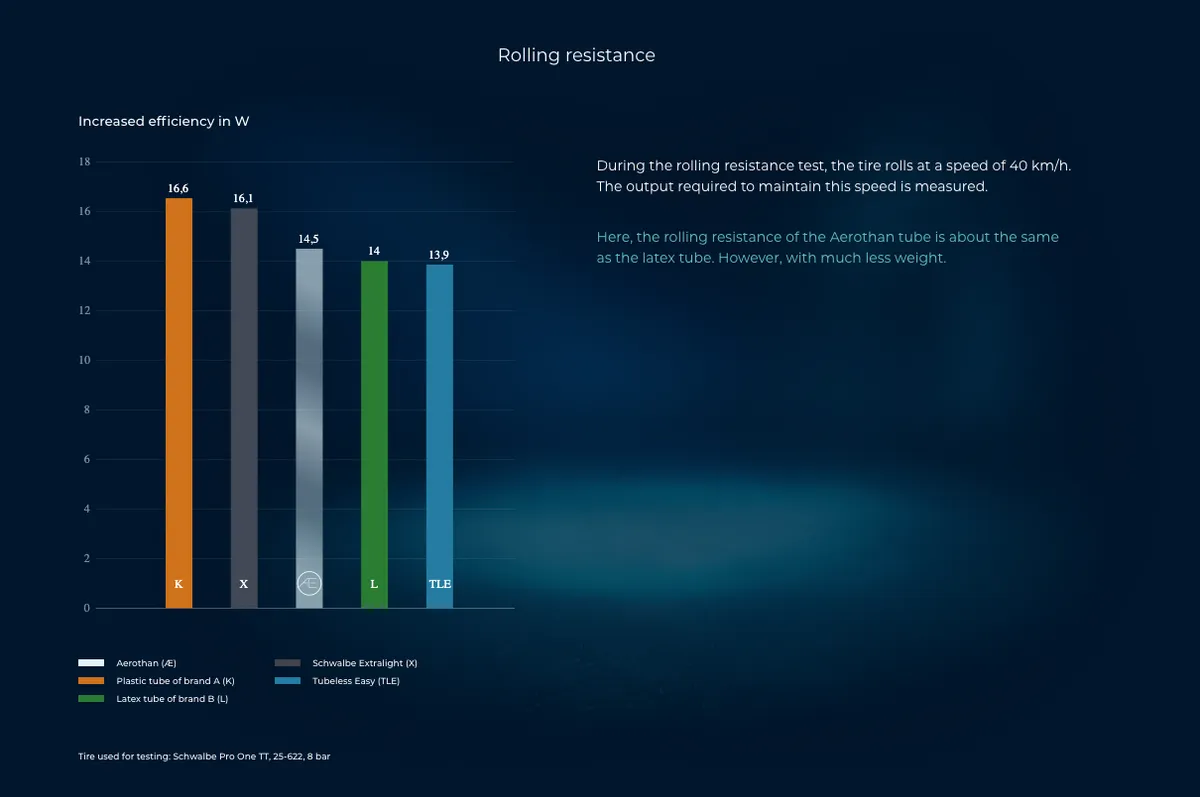

Schwalbe’s rolling resistance test, using a Pro One TT tyre, showed the Aerothan tube to be more efficient than an unnamed plastic tube from a rival brand and Schwalbe’s own Extralight butyl tube.

However, an unnamed latex tube and Schwalbe’s TLE tubeless system proved to be slightly faster.

In terms of ride quality, according to Schwalbe, the Aerothan’s patented laser welding manufacturing process allows for the production of “extremely flat seams”, which in turn enables a form fit between the tube and the tyre carcass, “resulting in extremely smooth riding”.

What are the Aerothan tubes actually like to use? We’ve received a selection of tubes to try out so will report back. In the meantime, let us know what you think in the comments below.