The mantra of thinking globally whilst acting locally is certainly taken to heart by the aptly named Local Bicycle Racks Company of Birmingham, Alabama. Their lead designer, Foster Phillips, has taken his experience as a product designer for consumer electronics and medical products, and helped design bicycle racks for use around the city.

In a town with a reputation for steel work, second only to Pittsburgh, PA, the Birmingham made racks could have a positive effect on encouraging ridership in a city that hasn’t, historically been seen as bike friendly.

If that were the end of the story it would seem like many others where skills in one industry are used to perfect products for another, and help encourage riding. But Phillips’ tale is a bit different. All the racks are made with support of local craftsmen from D. Brooks Bending who takes Phillips’ designs and craft the racks.

In this case the raw steel starts as straight pipe and bent into shape in a machine that came off a World War II battleship. And while the equipment to make the bends is going on 70 years old, it allows Phillips to act locally, when building. With help from BiciCoop, Birmingham’s bicycle cooperative, the end products are providing bicycle parking throughout the city.

“Birmingham doesn’t have a lot of cycling traffic,” Phillips told BikeRadar. “Although the bike community is small, it is very strong, and we thought it would be great if more businesses around town had racks. We also realized that most businesses really only needed bike parking for one or two bikes at a time.”

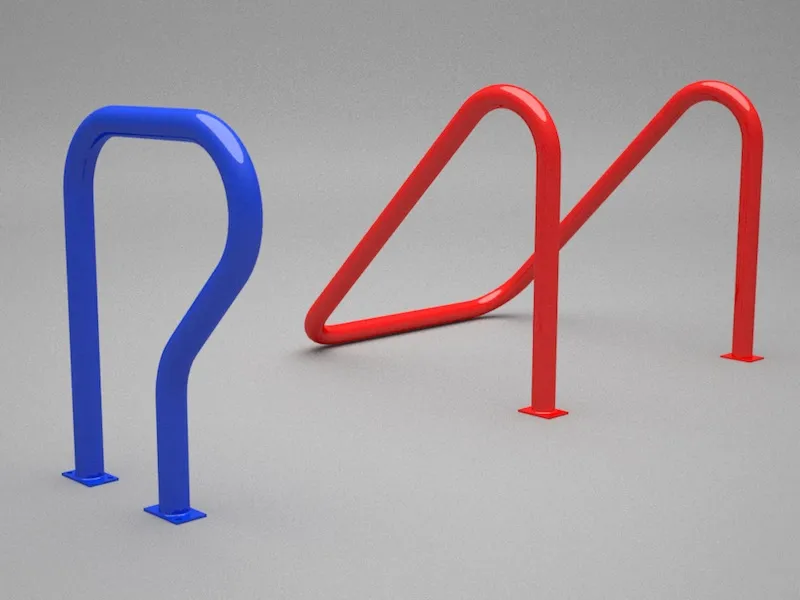

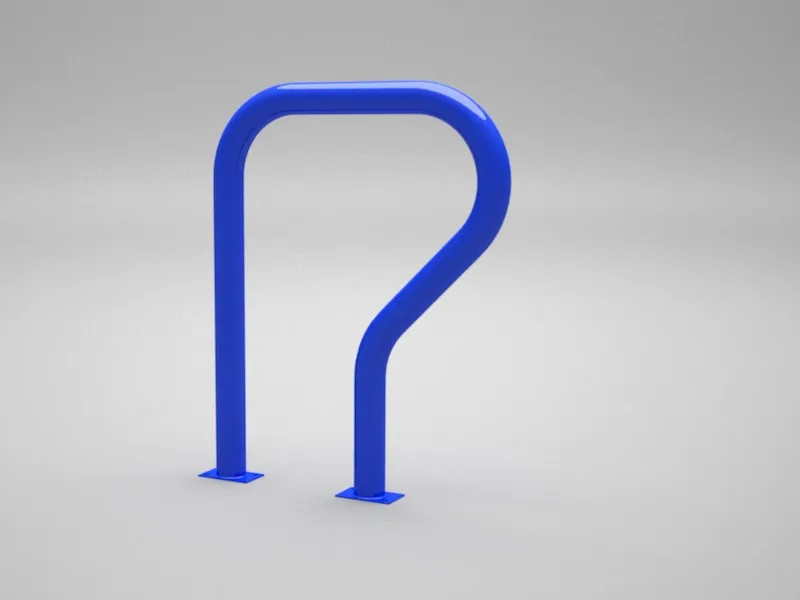

Instead of just using a standard industrial rack, he says that he took the overall shape of the rack’s design from the bike frame, so that the horizontal section of the rack lines up with the top tube and the angled section with the down tube. “If desired the front of the bike and the front wheel could be locked with one u-lock and the back of the frame and the back wheel could be locked with another u-lock,” adds Phillips. “Also the angled section allows bicycles of different sizes to line up correctly to the rack.”

Another early decision Phillips made was to powder coat the racks in bright colors, rather than galvanizing them. The use of powder coat makes for a rack that is smooth compared to the rougher galvanization. It also allows the racks to stand out, which in turn could help encourage local business owners to put out the racks out in front of their business.

Local Bicycle Racks' 4-bike rack in use

Making the racks locally was also important to Phillips. “I also really wanted to make the racks in Birmingham,” he says recalling the city’s history. “A while back Birmingham was an important steel town; and there are still a few businesses around that have ties to that time of Birmingham’s past. I found a small shop that excels in bending pipe and they were willing to work with me to get the first few prototypes created and refined, rather than requiring a large order at the very beginning.”

Phillips’ racks wouldn’t be possible with the help of the bending shop, he says. “The bending shop is really cool,” he said. “Mike Brooks owns the shop, but his father started the business in 1947 and they have two large bending machines that are stamped US Navy.”

While the official history of the machines is not documented, Phillips says that the guys at the shop think these were used on Navy ships up until the 1960s, before they were sold to Mr. Brooks. These machines are what allow Phillips to put a new spin — and bend — on traditional bike racks. “I wanted to make something a little different than the standard upside down U racks, thinking that it might be possible that a slightly different shape could lead to a better rack,” said Philips.

Phillips has plans for future projects, too. He told BikeRadar that next month he will install a few more racks at businesses in Birmingham, but he is, also, currently working to implement a more citywide solution for Montevallo, AL a college town about 45 minutes south of Birmingham.

He has also partnered with BiciCoop to find more sponsors that would like to put bike racks around Birmingham in the city’s community spaces. In addition to his civic projects Phillips has aspirations for smaller commercial designs including a home storage bike rack or shelf. “I am working on a design for a smaller, less expensive rack for one or two bikes, for areas that don’t need as much security as the first rack provides,” he says. “I am also working on a rack for eight bikes that could be a good fit for college campuses.”

And as part of the continuum Phillips’ bicycle racks, in turn, could inspire the next generation of Birmingham’s industrial designers.