3D printing is Fizik’s latest idea for saddles with its new Adaptive saddle tech, announced at Eurobike this week.

Saddles used to be a relatively simple idea: a base, some foam, cut to shape, bonded to base and covered with leather (or PU), and that’s it, done and dusted.

However, Fizik has been thinking outside the box recently, drawing in expertise to develop a design that has the potential to completely revolutionise saddle choice when it comes to personal preference.

The new Adaptive saddle has apparently been developed using decades of Fizik fit data and research and uses the carbon hull and carbon rails from the Antares Versus Evo saddle.

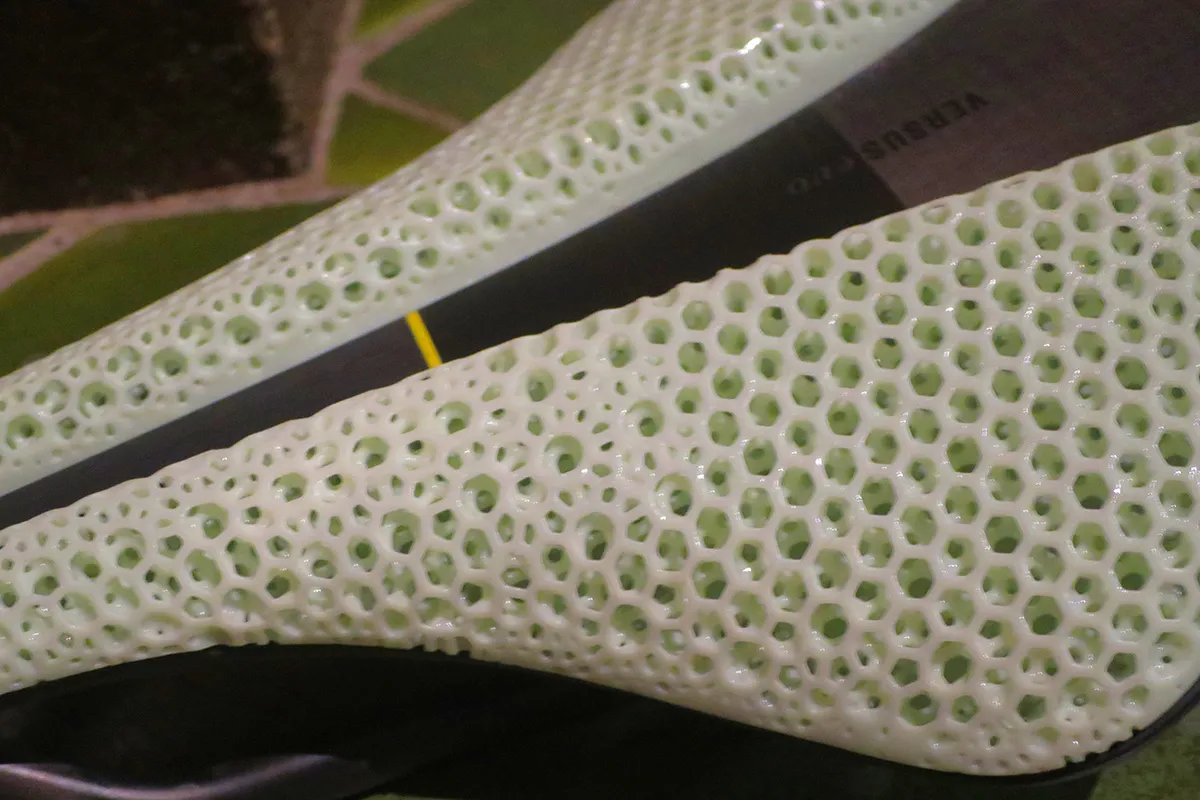

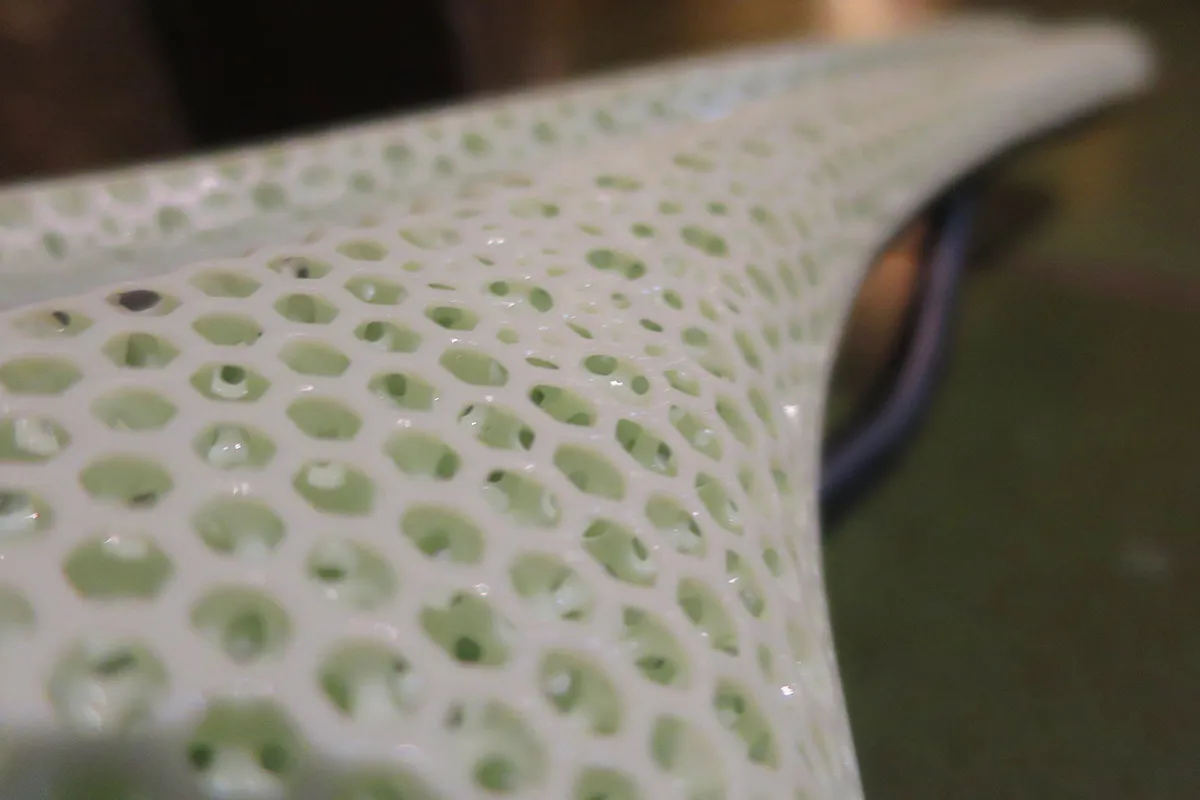

The upper padding, however, is a 3D printed polymer matrix from the innovative production company Carbon 3D that worked closely with Adidas on its new 3D printed running shoe polymers.

The Adaptive is very much intended as a proof-of-concept, it's not a production saddle as yet.

Fizik claims that by using 3D printing it can produce a multi-density, multi-tensioned material where elasticity, rebound, stiffness, support and cushioning can be controlled through the design of the material matrix.

Previously this would have involved multiple foams of different hardness bonded together — either using glue or heat which can have a detrimental effect on the material properties.

Custom saddle printing

It’s the long game that Fizik is talking about that intrigues us though. The brand says that the research and data it's accumulated throughout its history has allowed it to create an algorithm that not only follows its Spine Concept origins for ride position, but expands that to how you ride and not just what you ride.

Fizik says that when it originally came up with the spine concept — Bull, Snake, Chameleon — to reflect how you positioned yourself on a bike, the only choice of bike was a race bike. Now there's race, aero, sportive, endurance and even gravel to consider when it comes to rider shape on a bike.

These nuances have an effect on the pressures you put on a saddle, and Fizik claims the next generation of its saddles with Adaptive tech won’t only be its most comfortable, but will also be its most hard wearing and lightest too.

The next logical step, which Fizik is looking into, is a bike-fit related pressure tester; so you drop into your local store to get fitted for a bike, the fitter tests your pressure mapping on the saddle and Fizik 3D prints an Adaptive saddle that fits you perfectly.

Admittedly, this is a long way off because economies of scale apply to the 3D printing process (not to mention time), but in the long term who wouldn’t want a saddle that was custom formed to their posterior?

The Adaptive saddle is radical looking and I can’t help but wonder if the intended delivery date of before the end of the year will be hit.

It remains to be seen how successful a project this ambitious will be; we’re intrigued to try it out for ourselves as soon as we can get our hands on one.