BMC's headquarters and the new robotic manufacturing plant where their top-end Impec road bike is made are in Grenchen, right at the base of the Swiss Dura mountains and an ideal place to test a bike.

In scorching 38°C heat we were treated to 77km of the best local riding, with long and steep climbs, rolling hills, smooth and rough surfaces, a fast drag along the valley floor and even a little pavé.

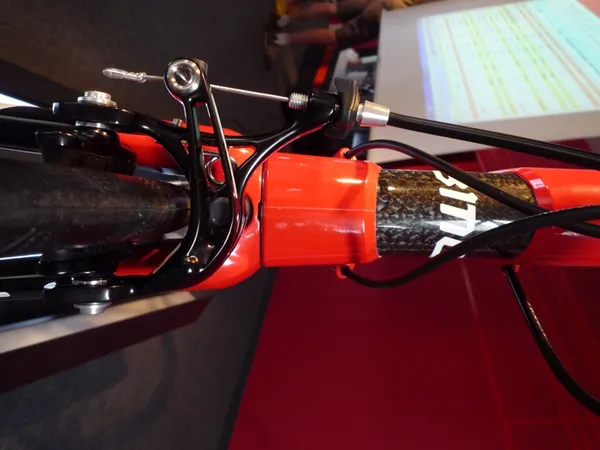

The Impec gave a great performance and the overall impression was of a bike working as a whole, with every component well balanced and unified. The handling is fantastic, with a rigid front end and excellent stability-boosting confidence to lay the bike into a corner at 40mph or sit on the top tube to wring out the last bit of speed from a descent.

Our test bike was a Team Version (ie. red), so it wore Easton EC90 wheels as per the pro team bikes. They felt quick but the braking was spongy and lacking power. The Noble (black) bikes use new Mavic Cosmic Carbone SLR hoops.

Comfort was a high priority during development so the Impec has low seatstays which allow the whole seat tube to flex, rather than just the section of above the top tube. Over the rougher back roads, the Impec did its best impression of a hovercraft, providing a level of comfort comparable to the exceptionally compliant 2010 Trek Madone 6.9 we’d been riding the previous weekend and even taking the worst sting out of cobbles.

The Impec's low seatstays allow the whole seat tube to flex for improved comfort

Extra comfort comes from the carbon-railed Selle Italia Flite saddle, perched on top of the Impec’s bespoke post which is available in a choice of three setbacks (-5mm, 10mm and 30mm). Our test bike was a race fit frame, 19mm lower in stack and 6mm longer in reach than the performance fit, so it was simple to get a focused position and there was scope to go even lower. A change of seatpost gave our ideal setback and we felt at home immediately.

The Impec is a stiff bike that climbs all gradients well, with no sensation of flex. That said, there wasn’t a feeling of granite-like rigidity either, especially compared to the single-minded LOOK 695 SR we’d been riding just two days previously. BMC say they selected an optimum level of stiffness and this probably explains why the Impec feels so well-mannered and accessible, without the impatient nervousness of some of the raciest bikes around such as Cervélo’s S3. That’s likely to give it a very broad appeal, from (well off) weekend leisure riders all the way up to Cadel Evans and George Hincapie, who are riding Impecs at the 2010 Tour de France.

Cadel Evans is competing aboard an Impec at this year's Tour de France

Further Impec project details

The Impec project began in 2005 with the desire of owner Andy Rihs to build the perfect bike. That led to the setting up of BMC's new factory at a (very conservative sounding) investment of £25 million. “We're a very ambitious team, ready to invest and thinking years ahead,” Rihs told us. “If you want to win you have to go your own way.”

The Impec factory is arguably more significant than the bike itself. Production capacity is 25,000 bikes a year, and BMC confirmed to us that the robots will soon be making cheaper frames and hardtail mountain bikes.

Impec is available in five sizes (50, 53, 55, 57, 60cm). Each bike will come with a bike bag, drivetrain protector, multi-tool, bottle cages and bottles. European prices are as follows:

- Noble (black): Shimano Dura-Ace, Mavic Ksyrium wheels, €6,999

- Noble (black): Dura-Ace Di2, Mavic Cosmic Carbone SLR wheels, €9,999

- Team Version (red): Easton EA90 wheels, €6,499

- Team Version (red): Campagnolo Super Record, Easton EC90 wheels, €8,499

The Impec is 'handmade by machines' at BMC's new factory in Grenchen, Switzerland