Back in January 2021, we lifted the lid on bike shortages. Well, inched it open, poked our noses inside and then slammed it shut. Was Brexit or the pandemic behind longer lead times?

Conclusions weren’t clear. Neither was an end to the shortfall. Fast forward to 2022 and the situation seems frozen, with queues for orders remaining longer than the convoy of lorries choking their way in and out of Dover. It begs the question: is there any light at the end of the very long production and supply tunnel?

“Sadly, it still feels very dark.” That’s Chris Ratcliff, business development director at Brighton-based Reilly Cycleworks.

“I heard Dominic Langan [CEO of distributor Madison, which brings multiple cycling brands into the country, including Shimano] saying he feels things will be fine by the end of the year. I’m not seeing it.”

Langan was talking at digiBike, a month-long online version of the iceBike trade show that Madison usually hosts at its Milton Keynes HQ. He was candid about the supply issues that have suffocated the industry over the past two years, specifically on the component side.

“The whole market changed dramatically from March 2020. The demand for supplies just went through the roof. And whilst we started with quite high stock levels, and we actually did pretty well for the first part of 2020, as time grew those supplies became depleted.”

Lockdown equalled reduced output coming out of Asia. Lockdown also equalled a potential bike boom. That equation was only going to result in delays and frustration.

“Our stock of Shimano is increasing every day and we are seeing some good positive trends on that score,” Langan continued.

“But there are certain lines where we know we’re going to be challenged for stock all year. And we’re going to retain the rationing that we’ve done on B2B to try to ensure that every customer has a fair opportunity to get that stock, so they haven’t got customers left high and dry in the store.”

Little to go around

It’s that enforced rationing that’s leaving the likes of Ratcliff unsated.

“What’s happening is distributors are being forced to drip-ship, say, groupsets to shops and bike builders like us, who have materials for frames. So, instead of a full groupset, we might receive a chain or crankset.

“I can see why they’re being forced into this situation, but it means we might end up having 47 left-hand shifters piled up next to five right-hand shifters. That doesn’t really help, especially when you pay for the stock up-front.”

Warehousing stock, says Ratcliff, results in a cascade of further costs from increased storage space and cranking up of insurance premiums.

This is at odds with the traditional ‘just-in-time’ production model, also known as lean manufacturing or lean production, where the focus is on producing exactly what’s needed when the customer wants it.

This reduces capital tied up in stock, as well as minimising waiting times and preventing over-production.

This build-up of product is a security risk, too, both in the warehouse and in transit, as highlighted by a recent incident in the Czech Republic where the country’s largest bike maker, Fun Bike International, had the equivalent of 10,000 bicycles’ worth of OEM (Original Equipment Manufacturer) finishing kit stolen en route to the assembly plant.

A truck driver transporting components from Germany was gassed to sleep in a parking lot by criminals, who then drove off with the Shimano stock.

Madison, like its fellow distributors, remains hamstrung by supply issues, exacerbated by a host of new openings, in particular workshop-only outfits.

“They would have joined the back of a stretched-out queue, exacerbating the order books being distorted,” says Mark Sutton, editor of Cycling Industry News.

The hopeful ironing out of these supply issues will come too late for some. Geoffrey Butler Cycles closed down in February 2021 after 40 years of business while, more recently, Bowman Cycles entered liquidation after what founder Neil Webb called an “absolute clusterf**k” of delays all the way up the supply chain.

Even biking behemoths such as Halfords have taken a hit: it recently revealed plans to buy and sell second-hand bikes in a move to bypass shortages and shipping distribution, suggesting customer delays could continue for some time yet.

Inevitably, cashflow is an increasing concern for many cycling businesses, especially smaller outfits that don’t carry the same weight as bigger companies when it comes to investment or obtaining loans.

And, of course, if you can source funds to cover your shortfall, at some point you need to start paying them back. “We all took out significant loans during the pandemic and now we’re having to do just that,” says Ratcliff.

“We’re not out of the woods yet and won’t be till sometime next year. I predict it’ll be 12 to 18 months before the dust starts to settle.”

While Darwin said only the fittest would survive, in the bike industry it’s seemingly the most flexible who’ll ride through the current storm.

According to the Cycling Industry News 2022 Market Report, 51 per cent of independent bike shops adjusted their main wholesale suppliers in the wake of shortages, looking further afield and to untested sources to fill gaps; 43 per cent went even further, taking it upon themselves to source goods directly to fill supply gaps.

The problem with this approach is that buying parts from retailers instead of distributors cuts profit margins, heightening those cashflow issues.

Throw in factors such as freight costs, which in some cases have reportedly tripled, and, if the bike business survives, inevitably the customer will see further cost increases.

The long-term albatross

Brexit’s trade ripples continue to flood the industry with doubt, uncertainty and expense. “The problem is it’s hard to unpick which one’s having the greatest negative impact – Covid or Brexit,” says Keith Noronha, managing director at Reynolds Technology.

The iconic brand, which has enjoyed a renaissance in recent times with the likes of high-tech 953 steel tubing, suffered from staff isolation and Covid-fuelled freight increases but, for the most part, remained resilient when it came to sourcing material.

Covid was a pandemic no-one could have predicted and its repercussions will be felt for a while yet. When it comes to Brexit, however, the seemingly self-inflicted trade wounds lead Noronha to laugh a derisory laugh.

“We sell so much into the EU, so you can probably guess we’re not fans. As a global UK business, we export to countries like the US, China and Taiwan.

“Brexit’s brought the same hassle factor for exporting into the EU as to these places. There’s extra costs and paperwork, and it’s often a two-way thing. We might ship steel out to an Italian frame builder, who’ll work with the metal and then send it as a built-up bike back to a UK customer.”

“That’s additional friction both ways. I know from a supplier’s point of view that you could easily add an extra £100 of administration costs onto an invoice of £200 to £300. It’s why I’ll tend to find someone local.”

Boom or bust?

Keith Noronha of Reynolds UK has witnessed many a peak and trough. Here’s his take on the future…

“Cycling is popular, but I don’t feel the rate of growth can be maintained, so what will happen? Take some of the smaller customers, the custom-builders who we deal with.

“They might deal with 100 sets a year, but are having to order way ahead of normal, so they’re asking for, say, 50 sets of steel tubing far ahead of selling the bike.

“That’s a lot of capital for them to find. It could be a risk. Then again, there’s a benefit to smaller companies who are agile and forge an array of supply lines. That’ll be a good foundation on which to grow.

“For us, it’s a real change in behaviour that some customers are placing orders for 2023 when, in the past, we rarely had orders three or four months ahead.

“Ultimately, the companies who are resilient and flexible are the ones who’ll be best placed to flourish once things hopefully settle down in 2023.”

Ratcliff and many of his contemporaries have followed suit by, if not fully avoiding sourcing from the EU, at least minimising their imports. This places further strain on the chain, which isn’t confined to bikes and components.

Steve Joughin is the founder of customised apparel outfit Pro Vision Clothing, based in Stoke-on-Trent. For cycling historians, Joughin’s also the winner of just about every amateur race held in Great Britain and was twice a professional road-race champion.

While online retailers flourished during the peak of Covid, Joughin’s customised offering faltered.

With no organised events or charity rides, few wanted bespoke branded clothing. Material delivery from Italy also arrived at a snail’s pace, albeit this wasn’t the greatest concern due to lack of orders.

Thankfully, with events back on the calendar, the company enjoyed arguably the strongest January in its 26 years.

Throw in a thriving corporate side – “One of our biggest clients is Waterworld,” says Joughin – and the future’s looking rosier. Well, it would without the thorn in its side.

“Our problems are more Brexit-related now,” the Isle of Man-born 62-year-old tells us. “In fact, it’s done as much damage to us as the pandemic. There are constant problems with getting hold of products due to custom and border controls.

“Take these damn administration codes. You might be one digit out and instead of waiting seven days for 200 pieces of kit to arrive, you’re waiting two months. All because of one digit.”

Joughin also bemoans a courier company he used who took out tariffs from the company’s account. “It turned out this was incorrect. We’ve obviously changed couriers, but are still waiting for a five-figure sum to be returned. We’re awaiting money back from HMRC, too. That puts pressure on any business.”

With the government’s inability to secure the trade deals it trumpeted when on the campaign trail in 2016, you suspect the impact of Brexit will be felt long after the Covid-fuelled issues that have affected every facet of the bike industry, from gravel bikes to electric bikes (Bosch has had problems supplying batteries, for example), clothing and helmets.

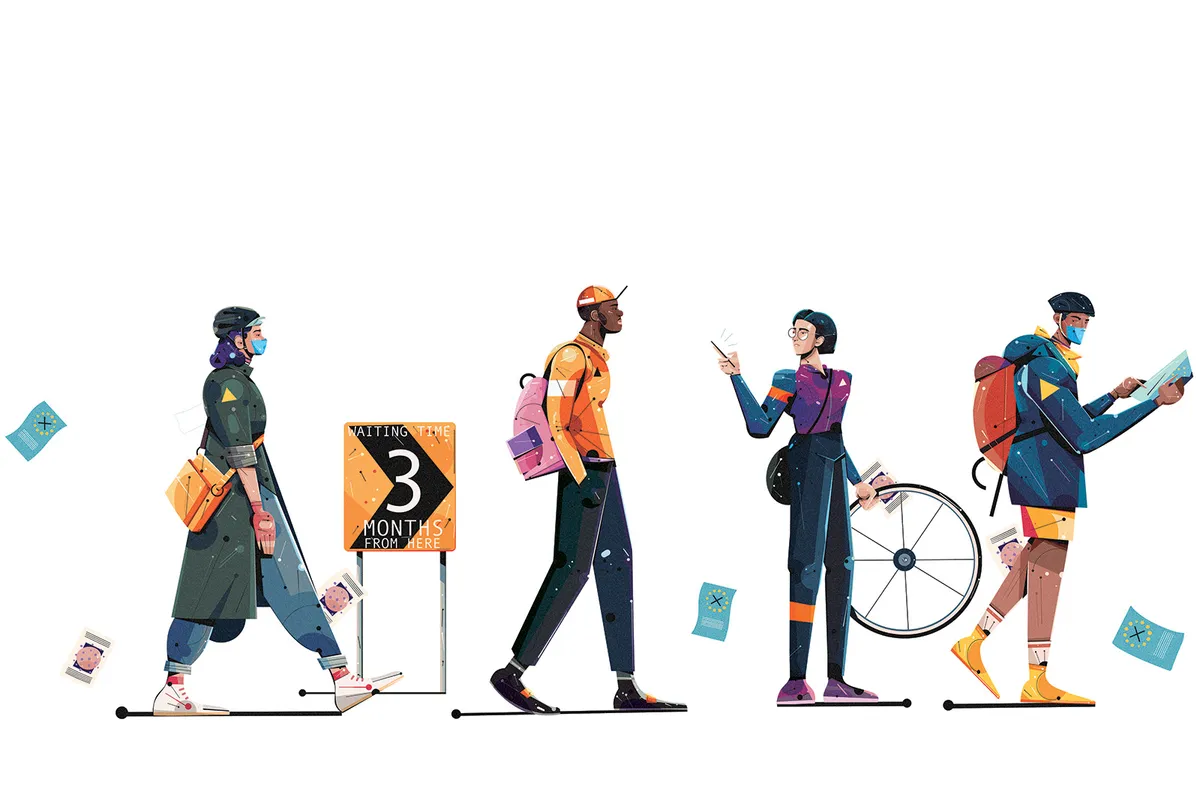

The current situation is a perfect storm of huge demand, restricted supply, rising prices and an increasing number of suppliers. For the consumer, that means significant delays; for the industry, stress and uncertainty.

“Core to our business are titanium bikes at around the £3,000 mark, so not high-end but not budget,” explains Ratcliff.

“We ask the customer for a £1,000 deposit. The problem is, with longer wait times of say five months – though we’re getting that down to three; normally, we’re four to six weeks and hopefully that’ll return soon – a customer’s circumstances can change dramatically. Especially now with the cost of living spiralling through the roof. Come delivery, they say, ‘I can’t now afford this’, so we have to return their deposit.”

Sutton has another take, one that could benefit you, but harm the industry. “In the face of rampant inflation, we could end up returning very quickly to a packed marketplace, where discounts become more prevalent.

"That might be good for consumers but not profitable [or arguably sustainable] for many in the supply chain. In fact, it’s quite dangerous given the number of brands fighting for market share. Too much stock can be as dangerous as too little in many respects.”

The future is bright(er)

Production, supply and pricing will chafe for some time yet. But there are positive signs.

Take shipping giant AP Moller-Maersk, which expects global supply-chain struggles to improve considerably this year, although the maze of Brexit will still have to be navigated with the UK performing worst of any country in 2021 for the median time containers spent in ports – 51 days against China’s chart-leading five and Germany's 25.

Bianchi has revealed plans for a new 30,000 square-metre HQ and production facility in Italy, while Vittoria is doubling tyre production with a ‘carbon-neutral’ plant in Thailand.

Closer to home, Brompton’s looking to invest £100 million in a new UK factory in Ashford, Kent. They’re snapshots of an industry looking to recover from, and excel off the back of, Covid.

Of course, uncertainty remains in many forms, from how big the industry really is once supply meets demand to the economic ramifications of the Russia-Ukraine conflict.

But let’s finish where we started and return to our metaphorical tunnel. “Is there light?” Sutton asks himself.

“There are so many variables at play to say conclusively. What I can say is that many manufacturers placed huge wagers on investing in production and supply, and some of these businesses are now in different leagues financially compared to pre-pandemic times, thanks to a sustained trend of investment in the industry.

“Those brands now have immense strength and resources to deploy, so in that respect failure isn’t an option – they’ll do what is required to complete their bikes and get them shipped – allowing for the caveat that global shipping remains a mess.

"The investment world sees cycling now as at a ‘mega trend’ junction: it ticks the green box, the health and fitness box, the transport revolution box, often the ESG (environmental, social and governance) box and several others, too.

“It’s probably not a coincidence that, with money flowing in and the industry showcasing its efficient and clean role in the transport ecosystem overhaul, sentiment politically has warmed drastically to cycling.

“That’s huge because once funding is unlocked to enable more cycling, then those bets made by manufacturers will be vindicated and cycling rates will jump as they have done in London and Paris, for example, since infrastructure has appeared.

"Mathematically, crowded cities really have no choice if they wish to avoid congestion and I think that idea is now settling with even those who previously were anti-bike.”

Talking shop

Bristol-based Bomber Bikeworks is run by Greg Lancaster. Here, the 'Bomber' reflects on how Covid and Brexit have affected him…

How has Covid impacted your business, both in the workshop and the shop element?

I was forced to take time off to look after and home school my children during the first lockdown, but when schools reopened I could work full-time again.

By then, there was an influx of new customers. The solid core of regulars were riding more, too, as a lot were working from home, which seemed to involve a three-hour ride every other day!

Also, the boom in Zwift helped the business as I offer smart-trainer servicing.

As for the shop, Covid has played a massive role in the shortage of parts. A surge in people riding during lockdown, combined with factories closing and being short staffed in Asia, left a massive hole in the inventories of companies such as SRAM and Shimano.

How has Brexit impacted both sides of your business?

It's hard to isolate the effects on the business due to Brexit and Covid, not to mention the knock-on from the Suez Canal fiasco.

I can’t say Brexit has really affected me, as I source all my parts from the UK, but I’m sure it's affected the suppliers massively.

How do you view the overall situation in spring 2022?

It’s all looking a lot better than it did. There’s still a shortage of full groupsets, but the majority of parts are now either available or within a sensible lead time.

My projected forecast for the year ahead looks good, my customer base is growing and I’m looking at expanding into another unit.

Will any problems be overcome by, say, spring 2023?

The rumour is that Easter 2023 is the magic date that things will be “back to normal”, but I question if it will ever be.

The last couple of years have changed the way I conduct business for the foreseeable future.