Intense Cycles are synonymous with two things - the revolutionary M1 downhill frame and the legendary Tracer trail bike.

Today, they continue to make world class mountain bikes and BMXs, with the highlight of the 2009 product year being the reinvention of the Tracer as an adjustable all-mountain rig.

In a rare interview, company founder Jeff Steber talks to us about Intense's extraordinary past, present and future.

A life in design

Jeff was interested from an early age in design, engineering, artistry and craftsmanship. He says, “Anything I got involved in, I would always try to deconstruct the product and reconstruct it to my liking. [For example] I learned to play guitar, so naturally I had to build guitars and put my ideas and style into it.”

Jeff discovered mountain biking in 1980, while working in R&D for a hang-gliding and windsurfing company in Southern California. He says: “A couple of us got some of the first Specialized Stumpjumpers to ride on the local trails when the wind wasn't blowing, and soon I was hooked.”

Ever the tinkerer, by the late 1980s he was itching to improve upon the rudimentary suspension systems he was seeing on local trails. His first frame was the Intense Spyder.

The legendary 1990 Intense Spyder was Jeff's first mountain bike frame

Built in 1990, it was a full-suspension cross-country frame using a Horst Link/MacPherson Strut-style design. By 1993, the hobby had overtaken the day job and he became a bicycle frame builder by trade.

“I consider myself a very lucky guy to be able to do what I love to make a living, to challenge myself every single working day and still craft all the prototypes and race bikes myself,” he says.

The Intense family

Too modest to use his own surname, the company name arose from what people said about Jeff's first prototype. “People’s reaction was ‘that’s intense!’ and the name was born," he says.

The company's reputation was cemented by its world-beating M1 downhill race frame, ridden to glory in the 1990s by the likes of Shaun Palmer - as well as numerous riders on other bike brands' factory teams who rode rebadged Intenses.

A 1994 Intense M1. This went on to become the most-wanted downhill frame of its era

The M1's modern successor, the M6, with Jeff and team rider Matti Lehikoinen

Even though Intense now produces 5,000 frames a year, they are all designed, fabricated and finished off in-house. Jeff is proud to be keeping a dwindling American tradition going, employing 35 people in a tight unit under himself and his business partner Marv Strand, who handles the administrative, planning and financial side of the business.

It is keeping the Intense family together that Jeff sees as his most important goal. He says, “The hardest thing is adequately dividing my time between being president of Intense Cycles Inc and designing and building the bikes. Luckily for me, we have a great staff of dedicated people and I always say that the whole is the sum of its parts and in the end that's what makes Intense what it is."

The evolutionary cycle

Jeff isn’t ready to accept the possibility of outsourcing yet, like so many of his peers have done. “I will always be hands-on, for me there is no other way," he says. "It would be like a clothing designer who didn't have a sewing machine or even know how to sew!”

In fact, Jeff uses this to his advantage. “I can basically fab up a new design in the morning, weld it and heat-treat it that night and be riding the next day. Having our own manufacturing facility is an amazing tool. It would be hard for me to not have this here.”

Jeff prefers the hands-on approach rather than outsourcing to the Far East

But Jeff is not so singularly minded that he just relies on his own feedback. Prototypes are sent out to his test and race teams for feedback, including UK downhill and 4X veteran Nigel Page, who helped develop the popular Slopestyle frame. Prototypes are also sent out to dealers. Only after gathering all this feedback will Jeff start production.

But it doesn’t end there. Jeff prides himself on his relationship with customers. Phone or email the company, or post on a forum, and it is often Jeff himself who will reply.

This is in part because he wants to support the people who enable him to continue doing the job he loves. It is also because he loves to learn from their feedback and continue the evolutionary cycle.

For example, he has produced a Tracer VP prototype recently that he hopes will meet the demand for those wanting to run Truvativ’s new Hammerschmidt drivetrain.

This using of “customer beta", as Jeff puts it, is one of the things that he feels ensures a loyal following for Intense, “as they feel close to the design and improvement of the products”.

An Intense Tracer VP all-mountain frame ready for welding

Form and Function

“Our tag line ‘Intense for life’ has multiple meanings for different people, but for me it means a dedication to performance, form and function,” says Jeff.

“My basic philosophy is that not only does the design have to be aesthetically pleasing to the eye - the visual, ergonomic and emotional - but it also has to work well in the real world under the conditions it is designed for, and then some.

“What I don’t want is a product that looks great but doesn’t work for crap, or works great but looks odd or scary or like it's broken.”

From Horst Link to VPP

Jeff had a long history with FSR (Horst Link) suspension designs, garnering many accolades from the cycling press, particularly for the original Tracer. But, never one to rest on his laurels, he jumped to it when Hans Heim and Rob Roskopp from Santa Cruz approached him at Interbike in 2003 to endorse their newly acquired VPP patent. It was a patent that Jeff had already admired so he was keen to incorporate it as their joint base suspension.

"For me it could become the Holy Grail, a suspension design that allowed for each model to be fine-tuned to perform best within the segment it is designed form," he says. "It has been a great working relationship with Santa Cruz and I have a lot of respect for what Rob and his team do and have done.”

The new Intense Tracer VP features a second generation VPP suspension design

Although VPP has been successful, Jeff and Rob knew it had two problem areas. Jeff is confident these have been solved with the second generation Intense VPP design.

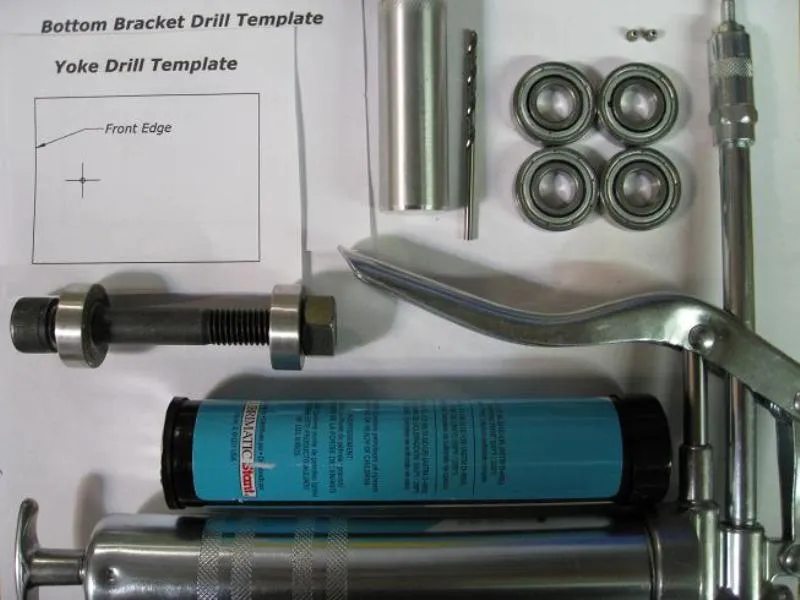

“Firstly, the first generation VPP designs were hard on bearing systems that worked great with the FSR designs, which has led to our use of the new angular contact bearings and Zerk-fitting grease ports for the second generation," he says.

"Secondly, chain growth was a problem, especially in the granny ring.” Jeff feels this has been solved with changes to the linkage positions and shock rates. He says: "As the new system actually varies the shock rate less than the old one, the result is a much more active feel in the early part of the stroke and more linear towards bottom-out. As a result, maximum chain growth is considerably less.”

The result has been positive reviews of the new Santa Cruz Blur LT and Intense Tracer VP. A revamped Nomad and Uzzi are also due to be launched.

To ensure previous customers are not left out of the improvements, Zerk-fitting grease ports will be made available to retro-fit to existing Intense VPP frames.

Zerk-fitting grease ports will be made available for older Intense VPP frames

How the new Tracer VP came into being

Jeff has decided to take Intense in a slightly different direction to Santa Cruz by offering the new designs with adjustable travel.

"At some point we realized we had 12 models in the Intense line and we were always running low on one model or another. So, we decided to thin the herd a bit, just concentrating on the most popular segments in the line. This decision had to be made if we were to continue functioning as an in-house American production facility.”

Jeff also felt the adjustability of the new generation bikes would meet customer need. "In these uncertain economic times, I thought it would be less likely that people would be able to afford to have two or more hand-built bikes for different purposes. It would be better to have a bike that that could evolve if their riding style changes.”

He chose to make a new all-mountain/trail bike first, as it is the biggest MTB market. As this area is so competitive, he realised he “needed to make something that really stood out from the rest, in both form and function”.

The new Tracer VP was born.

Intense's new Tracer VP all-mountain rig features adjustable travel

Half an inch is all it takes

On paper, the Tracer VP's versatility seems limited. But Jeff says: “The bike really has two different personalities when set up in the 5.5in or 6in travel settings, which can be matched by either 140 or 160mm forks, dependent on the trail and the rider’s inclination.”

The difference in axle-to-crown height of each fork length alters the geometry of the rest of the bike, resulting in a 69-degree head angle with 140mm fork and 67.5 degrees with 160mm fork.

In addition, Jeff feels that using a 1.5" head tube also adds versatility. He says: "It allows the use of all three headset combos and adds a lot of strength in conjunction with the large-section mono top tube.”

Nigel Page sums up the differences in travel and geometry as follows: “In the 6in setting the bike seems to sit into its travel a bit more like a DH bike, which makes it more stable on the really fast and technical stuff. Whereas in the 5.5in setting it stays sat up a little more to blast singletrack.”

Nigel says he rode the bike down the Schladming World Cup downhill course in the 6in setting and was amazed to find he wasn’t a lot slower than on his DH bike. With the added bonus, as he says, that “I could have ridden back up again on the Tracer if I had the fitness!”

Chief Mountain Biking UK and What Mountain Biketester Guy Kesteven is equally full of praise for the Tracer VP, calling it “everything a modern trail mountain bike should be… remarkable in its ‘feels right whatever you do’ versatility, with superb suspension, and totally distinctive ‘doubles as art’ build quality.”

New Tracer VP frames at Intense's factory in Temecula, California

The near and distant future

Jeff is hopeful that the new adjustable long-travel Uzzi replacement will be ready for production in February 2009, with other new bikes following later in the year.

But his greatest hope is that the trimming of the herd will increase production to meet demand. “In the past this has hurt us, as people will only wait so long and understandably some ended up looking elsewhere. Meeting the demand, for mine as well as my employees and the customers’ sake, will therefore be my major goal for 2009 and beyond.”

The new Intense Uzzi with Rock Shox Totem forks