Cassettes have become more and more expensive as the number of gears has increased and the quest for saving weight continues. But Zuma Innovation has a patent that could radically reduce the cost of replacing worn components.

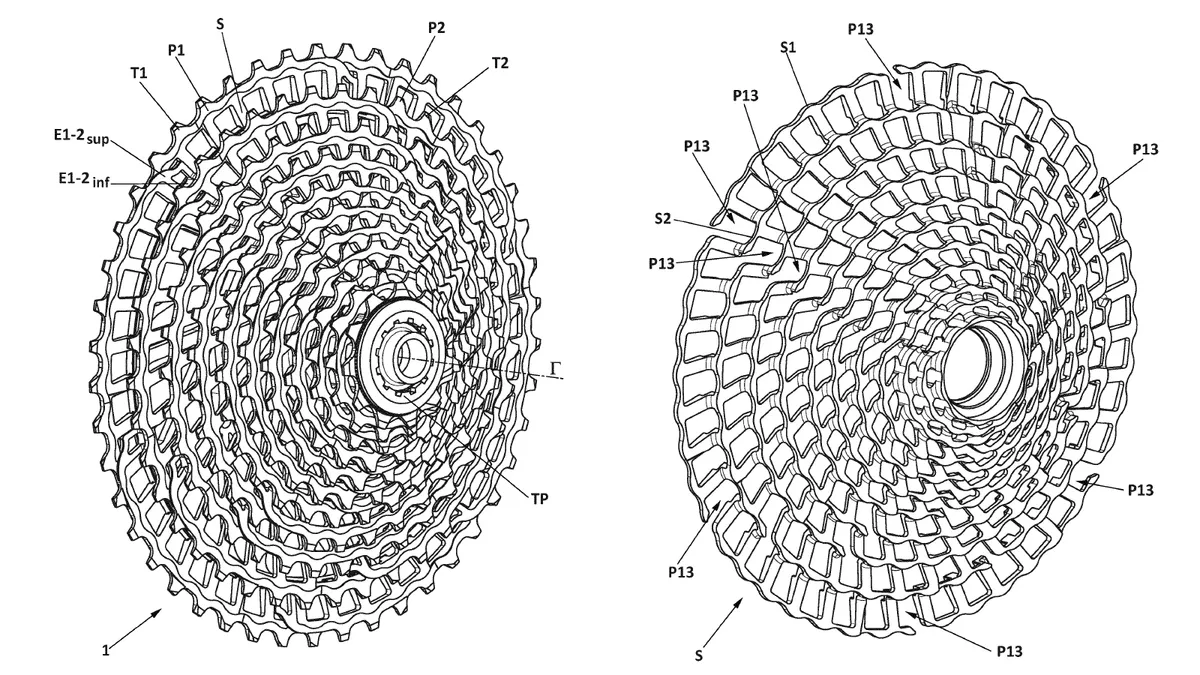

Modern high-end cassette-design often sees complex machining or a mix of exotic materials to achieve wide ranges and an acceptable weight.

High-end SRAM cassettes feature a cog cluster that is machined from a single block of steel (except the largest aluminium cog), whereas Shimano uses a lightweight carbon-fibre spider with pinned cogs.

While the engineering is impressive, once the cassette is worn out there’s not much you can do other than replace the whole unit. This is frustrating as it’s only really the teeth that are worn.

Get your cogs on

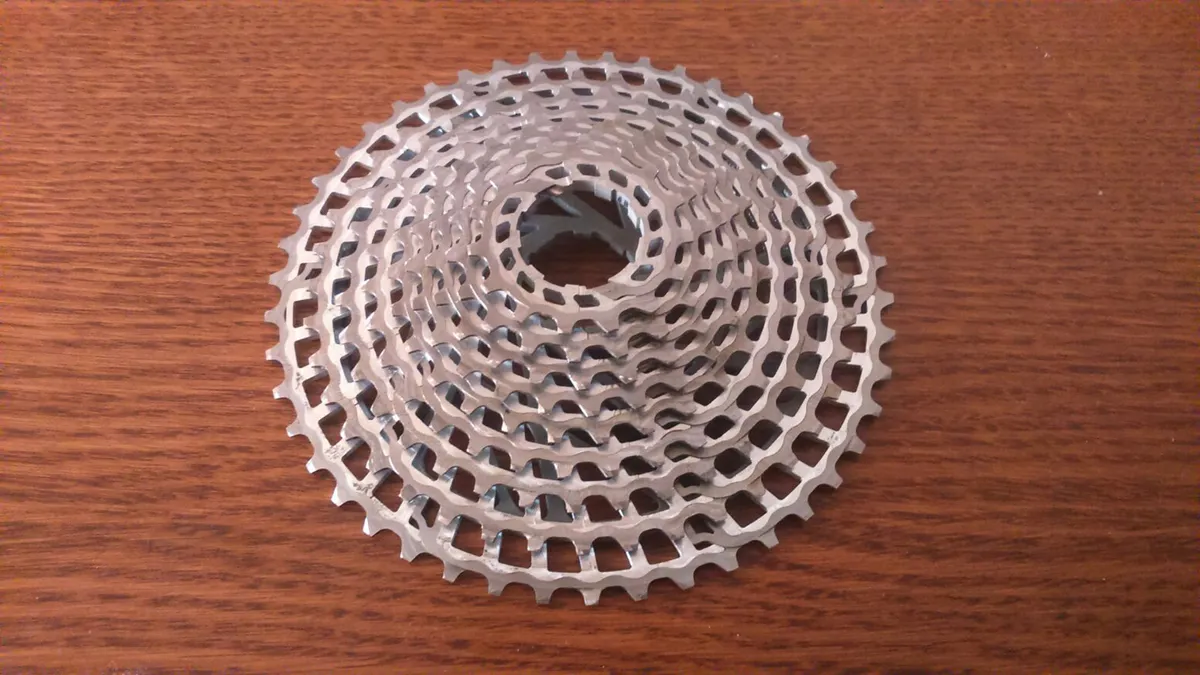

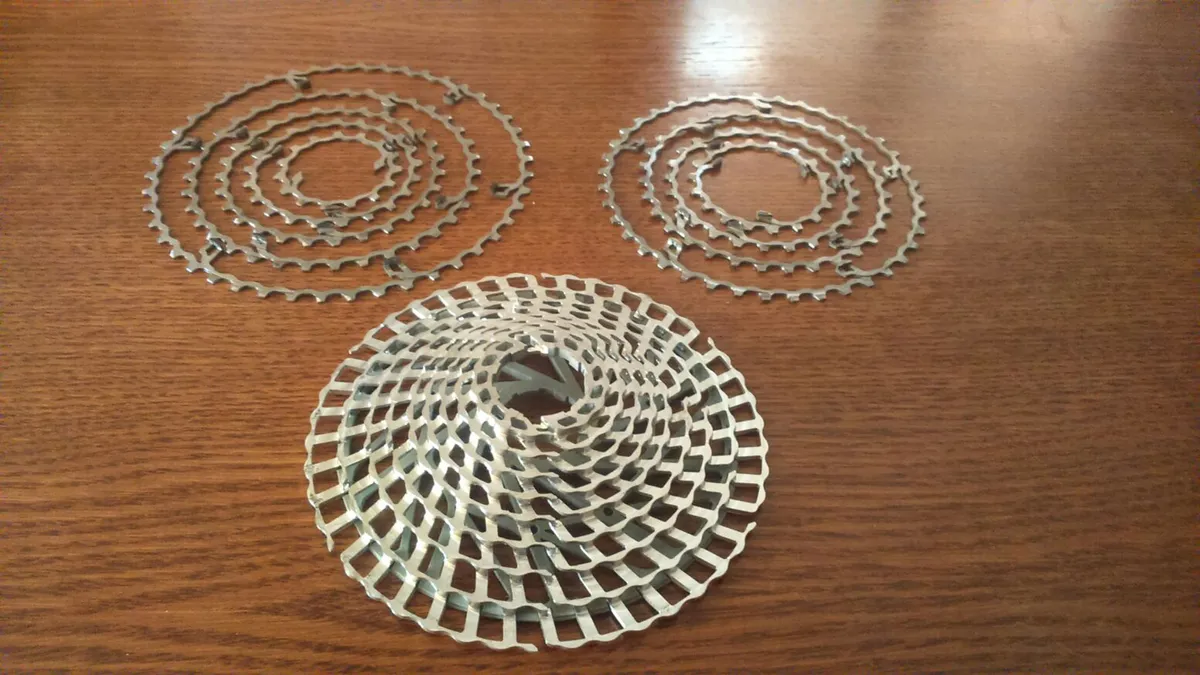

The patent outlined by Zuma Innovation aims to change that, offering replaceable steel cogs that slot on to a lightweight carrier. That means that the complex part of the cassette — the machined carrier — doesn’t have to be replaced. It will be a one-time cost when buying the cassette.

The steel sprockets are manufactured separately. Due to the relatively simple form, they can be stamped — a process that is already widely used for existing cassettes. This process provides high productivity and, in turn, should help reduce the cost of production.

Of course, steel adds durability and unlike many cassettes today, Zuma’s design proposes a steel (rather than aluminium) sprocket for the largest cog too.

Put your metal where it’s needed

The outlined design aims to benefit from the favourable characteristics of each material used. That means the carrier can be optimised for weight, while the consumable sprockets can be optimised for durability and cost. This aims to provide the best of both worlds, yet in a configuration that will help save costs in the long run.

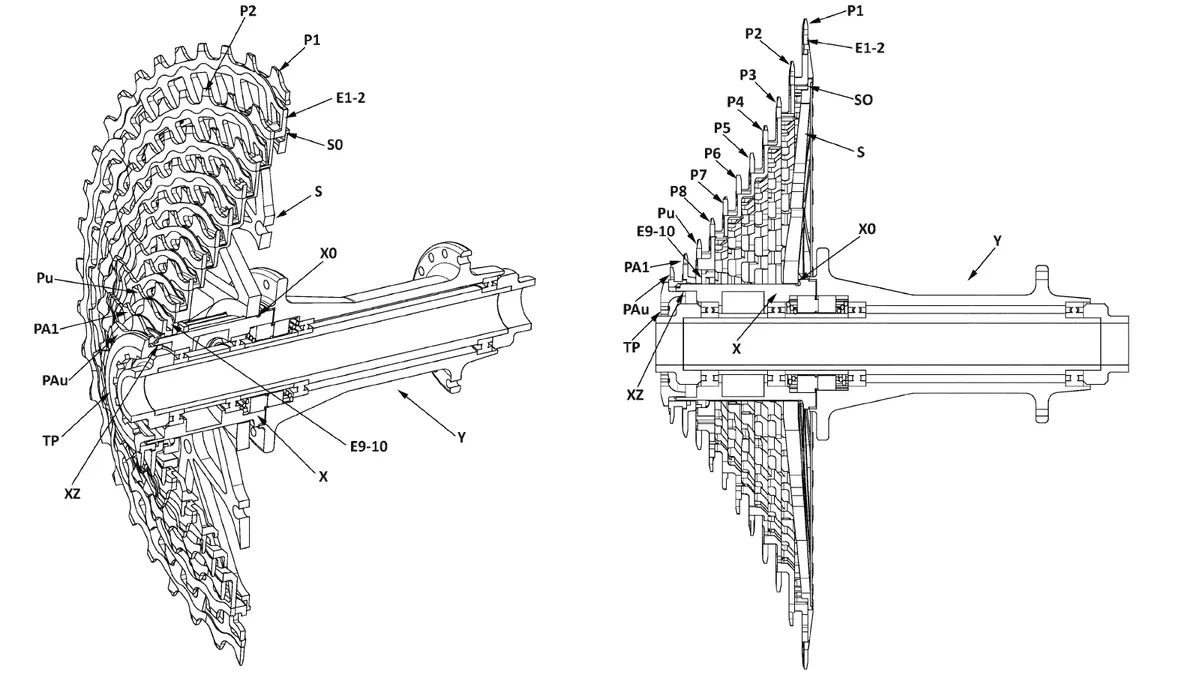

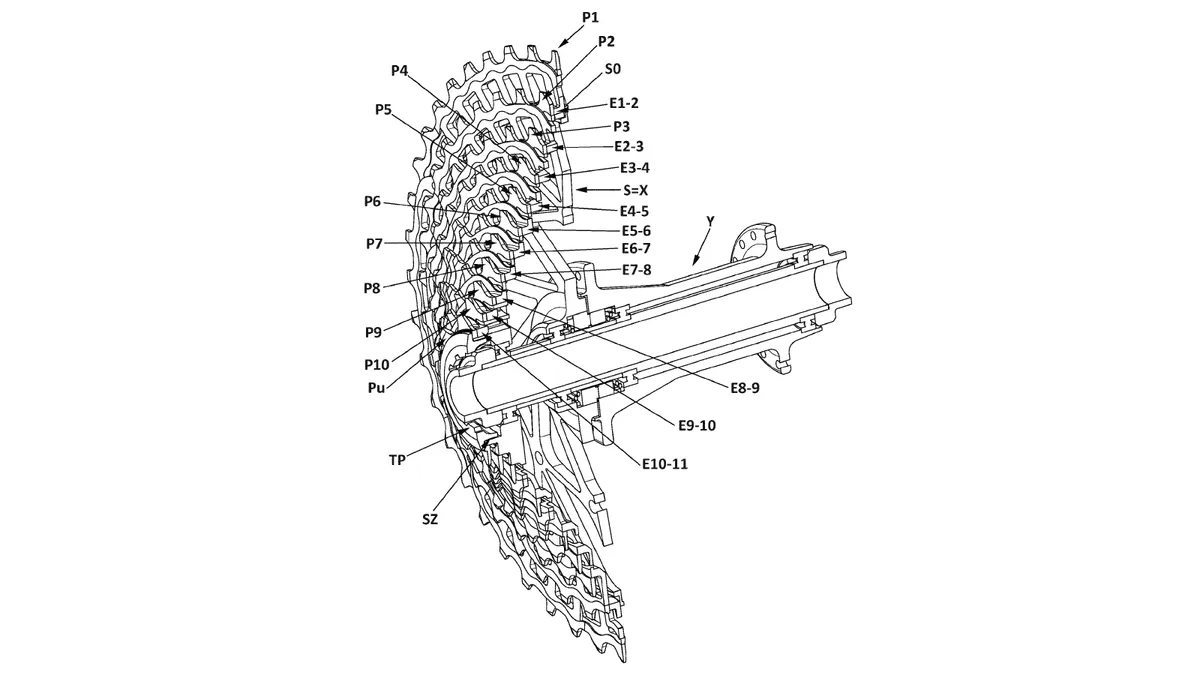

The carrier

The carrier is the load-carrying element that transmits torque to the wheel. Making up a significant part of the structure of the cassette, it is optimised for low weight.

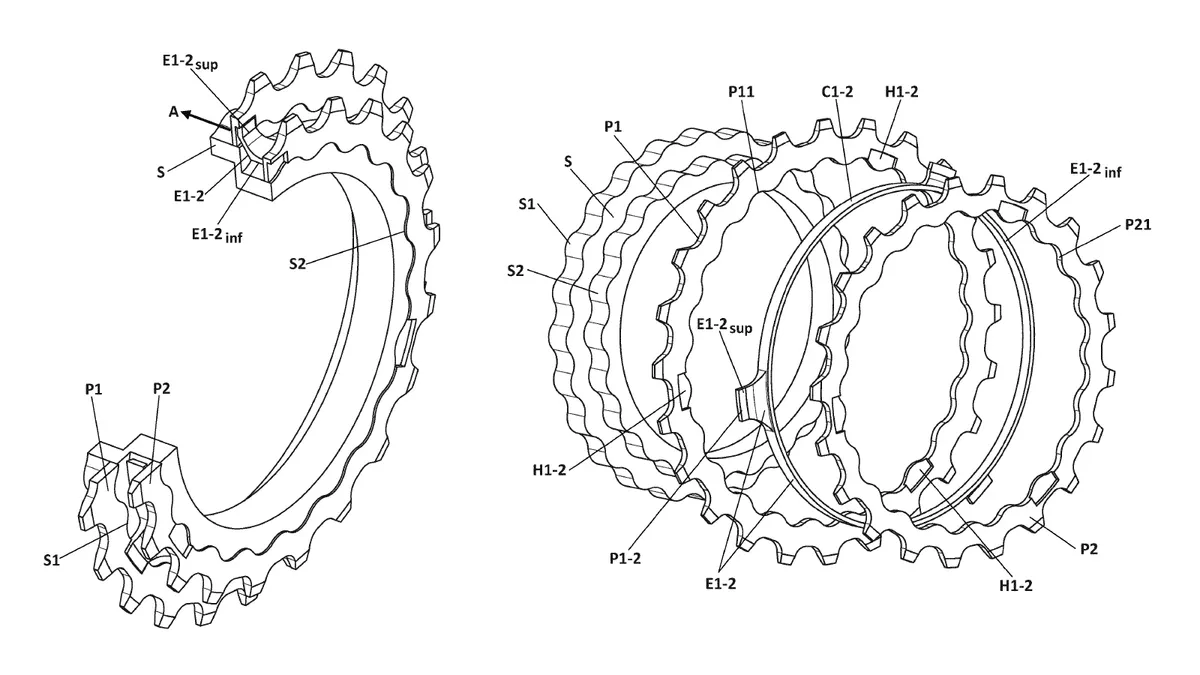

The main structure is essentially a hollow shell similar to the X-DOME structure found on SRAM cassettes, and the critical part of the carrier is the interface between steel cog and lightweight carrier. This must provide a secure mount for the mounted cogs while withstanding the torque input from the mounted sprockets.

Given that the carrier is likely to be made from a lightweight material, such as aluminium or magnesium, it would need to be carefully designed to avoid the steel sprockets biting into or marking the mounting surfaces — this is a similar concern on lightweight alloy freehubs.

It is also key for this interface to remain in good condition, given that it is intended to be used indefinitely as cogs are replaced with use.

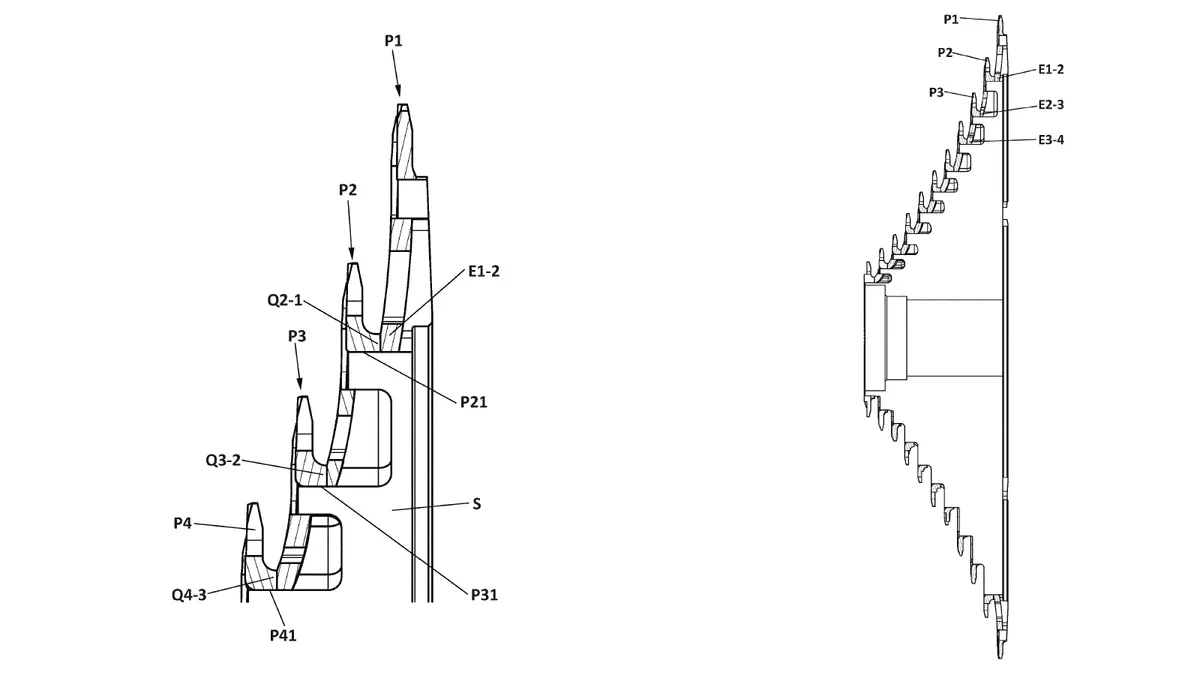

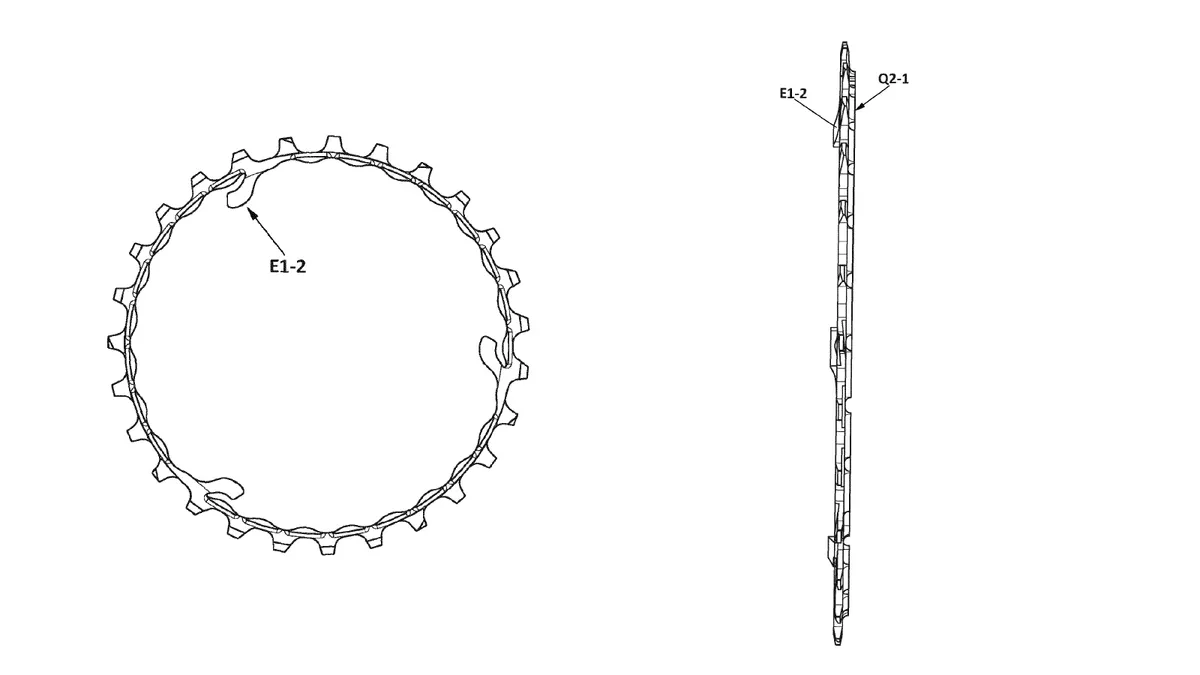

The configuration proposed sees the interface designed as a wave, providing a large surface area for the radial force to be transferred and spreading the load effectively across the surface of the carrier.

The geometry of the interface should also effectively lock the sprocket in place when a load is applied, further preventing any lateral slippage.

The sprockets

Despite the removable sprockets, the cassette needs to act as a single structural unit while riding. With the cogs fixed rotationally to the ‘wave’ interface on the carrier, the Zumo design uses a standard cassette lockring to apply an axial preload. This is transmitted from the smallest sprocket, all the way up to the largest to hold everything securely in place.

This is achieved by the unique shape of the removable cogs.

Legs (E1-2) mate with the relevant point on the carrier (S2). An axial protrusion (E1-2 inf) contacts the sprocket below, resulting in the preload being transferred through all the sprockets.

In the case of the largest sprocket, the leg hits a stop (S0) which fixes its axial position at the top of the cassette. These preload abutments also act as shifting ramps for the chain. All potential wear from shifting is taken by the steel sprockets rather than the carrier. These legs become less pronounced as the sprockets get smaller further down the cassette, but serve exactly the same purpose.

A key part of the sprocket design will be ensuring it has a large enough base width, to provide a large surface area to prevent marring of the carrier. This would also help prevent ‘rocking’ of the sprocket on the carrier.

The extension Q2-1, provides a wider base but also maintains accurate spacing between the cogs, creating an offset from the cog above.

Finally, at the bottom of the block, the patent suggests that spacers could be used between the smaller sized sprockets to transfer the preload. This is likely due to the limited space in this area making it easier to use a slightly simpler design.

Works on existing freehubs…

The novel cassette design works with a standard freehub.

In the patent, the two smallest cogs don’t actually sit on a carrier, but instead mate directly with the freehub. This is similar to many other cassettes where the smallest cogs are too small to fit on a spider and are attached separately.

...or a new-fangled integrated one

However, there’s another more interesting proposal here too. The patent suggests the traditional freehub could be replaced by an integrated carrier. The steel sprockets could then be mounted directly to this.

This makes a lot of sense and is a logical progression of the design. It would also save significantly on weight, with no traditional freehub body required. There is also no reason why such a design could not be retrofitted to existing hubs, as the overall dimensions would not really be subject to change.

Interchangeable freehub bodies are common, and this carrier would effectively be just another option.

I’ve seen something similar from Hope in the past, albeit with the whole cassette and freehub assembly in one unit.

That could result in an even more competitive ‘system’ weight, considering that the prototype version of the non-integrated cassette is a claimed 275g for the 11-42T and 318g for the 11-48T version.

The replaceable cogs could also allow a small amount of customisation of gear ratios (within reason). There seems to be no reason why, within the tolerances of the sprocket mount diameter, each step couldn’t be provided in several different tooth numbers.

Design challenges

A main challenge could be ensuring the interface between carrier and sprocket spreads the load evenly to avoid the steel cogs biting or marking the softer carrier material. This would be the key factor that affects long-term durability of the carrier, but is not an unprecedented engineering problem.

There is a similar interface from Miche, which is designed to allow fixed track sprockets to be changed easily. This provides obvious real-world proof of concept for the idea.

The forces acting on the individual sprockets would also need to be carefully considered, to avoid any lateral slippage.

That’s especially the case in lower gears (larger sprockets) where the chain angle will result in a component of force pulling the cog towards the outside of the wheel (towards the smallest cogs, for example).

It will be important to ensure there is no shifting of the sprockets due to (potential) elasticity or flex in the legs. Likewise I envisage inward bowing of the sections between the legs, which have no direct preload holding them in place.

Zuma claims to have optimised the cog carrier interface to avoid these issues. The wave interface creates high friction when the sprockets are under tension from the chain, preventing them from slipping due to any component of lateral chain force.

In use, the sprockets are essentially held in place by friction, when no load is applied the preload on the arms keeps everything in place.

In addition, it is likely important to consider side-to-side ‘rocking’ of the sprocket on the carrier. Zuma Innovation claims this is not a problem due to the low cog height. I also imagine it has tried to maximise base thickness to increase support of each sprocket.

This novel design does bring with it some potential complications. However, I have no doubt careful consideration of the interface, preload points and dimensions of the sprockets can eliminate such issues.

From prototype to product

Indeed, given that Zuma Innovation has a working prototype, I see no reason why this idea can not make it to being a commercial product.

Clearly, given the complex machining SRAM does on its high-end cassettes, manufacturing the carrier for this design is possible. Indeed, the 7075-T6 aluminium alloy Zuma Innovation is using for its prototype carrier is likely easier (and therefore cheaper) to machine than SRAM's one-piece steel cassettes.

Likewise, using stamping processes to form sprockets is a well-established practice.

Details such as the design of shifting ramps are aspects that are already well understood in the industry, as is the design of the freehub mounting.

There is also no reason why the design can’t be adapted to different freehub body standards, but I am particularly interested in the integrated carrier concept outlined in the patent.

Zuma mentions a target price for a full cassette at somewhere between XT and XTR level, and a full set of replacement cogs (11-speed) at half that price.

Can you help?

While I'm rather keen on this design, it will be interesting to see if it does indeed provide all the performance of a high-end cassette with much lower long-term maintenance costs — it could be a great success…

Zuma Innovation is currently looking for manufacturing partners to turn this concept into reality.

For more information and to get in touch, you can visit Zuma Innovation.