Titanium is a metal that has an atomic number of 22 and its chemical element symbol is Ti – which is fitting, as many people in the bike industry often refer to titanium as ‘ti’. This metal doesn’t weigh as much as gold, but like that precious metal it’s corrosion-resistant and can be lustrous in a refined state. And unlike gold or silver, titanium is as strong as steel when properly processed.

While gold has long been sought after as a precious metal, and iron was used to forge tools and weapons for eons, titanium is a relatively new metal. It was only discovered in 1791 by William Gregor in Cornwall, Great Britain. German chemist Martin Heinrich Klaproth rediscovered the metal about four years later, and named it after the Titans of Greek mythology.

The name is fitting because, for a brief time, it was the material of choice for the titans of the bicycle world. In the 1990s, titanium had its heyday as a viable high-end frame material. It was lighter than steel, stronger than aluminum and easier to work with than carbon fiber. Numerous manufacturers jumped on the bandwagon, but perhaps none of it would have happened had it not been for the Cold War.

“It is fair to say that Russia’s extensive use of titanium for military projects spurred modern day development of titanium,” said Mark Lynskey of Lynskey. “Russia’s development was centered around grade two or pure titanium, as they did not have sufficient sources of vanadium to strengthen the metal.”

Unlike carbon fiber, titanium can hold up fairly well on impactIt was in the 1950s and 1960s that the Soviet Union actually pioneered the use of titanium in military aircraft and submarines. But the United States was close behind, and throughout the Cold War titanium was actually considered a “strategic material” by the US government. So important was the metal to the military that large stockpiles of titanium sponge were maintained by the Defense National Stockpile Center, which was only depleted around the year 2000.

Military connections

Just as some of the fastest bikes were made with titanium in the 1990s, the metal was used in what still holds the record for the fastest military aircraft, and it was this project that gave birth to the development of the aerospace-grade titanium that made its use in bikes possible.

“The SR-71 Blackbird project in the US brought the 6Al-4V alloy to production levels,” Lynskey told BikeRadar. “The most direct advance for bicycles came in the development of the 3Al-2.5V alloy. Its primary use was, and still is, hydraulic tubing for commercial aircraft.”

Interestingly, the use of titanium in bicycles actually began during the height of the Cold War. “Titanium in the bicycle frame format has a long history,” said Jon Cariveau, spokesman for Moots. “Teledyne started making bikes made of titanium in the 1960s.”

The Teledyne Titan was one of the first titanium production bikes, along with models from Flema in Germany and Speedwell in the UK. These three brands all experimented with titanium in the late 1960s and produced commercial models in the early 1970s.

While the Flema Super might have been the first titanium race bike, the Teledyne Titan was likely the first mass-produced titanium bike, although not that many were made. One of the problems was the grade of titanium that was available in the commercial markets at the time.

“The first bikes were built of unrefined titanium,” said Cariveau. “There was no alloy at the time, so it was really a very soft material. The development of aerospace really helped make it a material that was usable in bikes.”

And just as the Cold War helped the development of titanium production and its use as an industrial material, the end of the battle opened the door for its use in commercial products.

“It is accurate to say that consumer use of titanium is trickle-down technology from military and aerospace developments, as is carbon fiber,” said Lynskey.

Competing with carbon

By the year 2000, titanium was a reliable alternative to steel in sporting goods, notably golf clubs and bicycle frames. But that other super-material, carbon fiber, also came into its own, taking the cycling world by storm.

“Carbon has without question become the mainstream material for cycling,” added Lynskey. “It’s very workable, able to be mass produced at relatively efficient costs, and has very good strength to weight properties. Titanium’s Achilles’ heel is that it is very expensive.

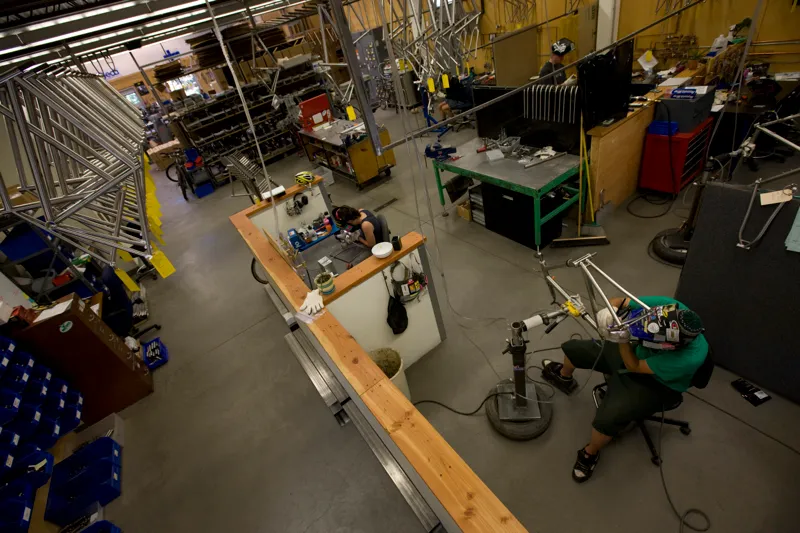

“As a raw material it’s very costly – you can buy a mass-produced carbon bike frame for about the same cost as the raw materials in a bike frame. It’s also very costly to work with in that much specialized equipment and uniquely skilled labor are needed.”

Moots, in Colorado, has built a loyal following for its titanium bikes

But despite these issues, titanium remains popular with certain riders, which is why companies such as Lynskey, Moots, Dean, Litespeed and Firefly remain in business today.

“Even with its cost constraints, titanium will always remain popular for cycling enthusiasts as it possesses the best balance of light weight, strength, durability and damping,” said Lynskey. “Aluminum and carbon fiber both are lightweight materials but fall short in durability and damping compared to titanium. The best benefit to a rider is – when properly designed – titanium can offer a very solid and stiff frame that is also very forgiving and comfortable.”

Moots’ Cariveau agrees and says that titanium has another advantage that’s often missed by those who watch the pros ride on carbon fiber in the major races.

“Carbon fiber is a really beautiful material. It is only going to get better, but when you’re looking at real world situations where you aren’t handed a new bike when you crash, you see the value in titanium,” he noted. “A bad crash on a mountain bike can just destroy the carbon fiber frame, and while it can be warrantied, you have to deal with stripping the parts and sending it back. Titanium can endure those spills that carbon cannot.”

The shape of things to come

Interestingly, the future of titanium could be in printed materials. While carbon fiber can be manipulated into shapes that require precise bending and welding, its strength is in its long fibers.

But because titanium begins life as a dust-like material – which is often found in sand, making Australia one of the largest suppliers of the metal – it likely has more of a future in 3D printing. It could mean that bikes designed on computers could have frames as aerodynamic as carbon fiber and as strong as steel but printed out and ready to ride.

“We have looked into this, and over the next few years we hope it will give us the ability to create more complex and aesthetically pleasing parts for bikes,” said Lynskey.