Component giants SRAM are generally characterized as an American company based in Chicago, Illinois and rightfully so – that's their main base of operations, after all. However, they've diversified into a decidedly global entity. These days, nearly all of their drivetrain development is done in a lesser known – but arguably more significant – facility in the German industrial city of Schweinfurt, about two hours outside of Frankfurt.

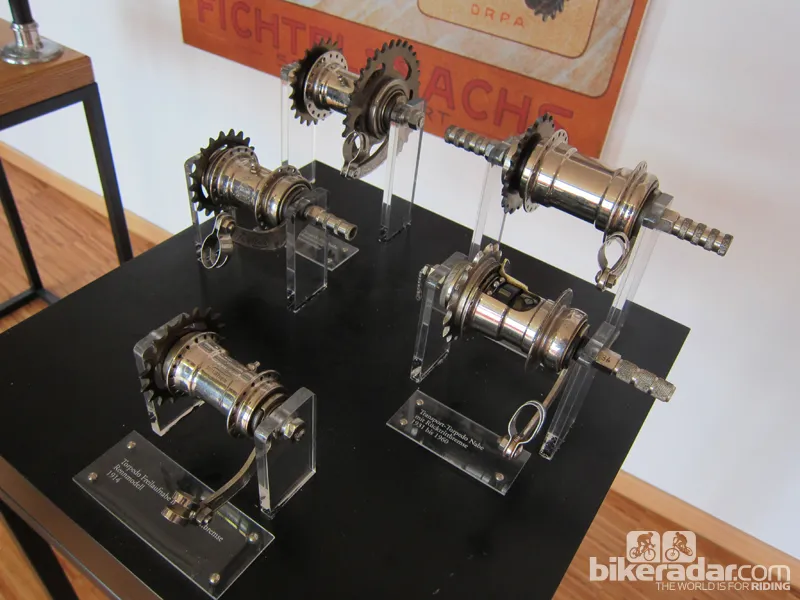

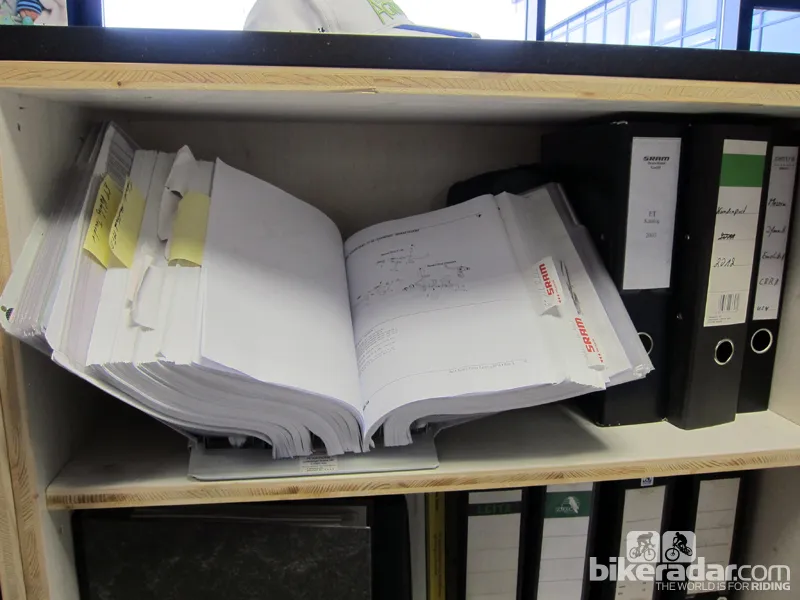

SRAM built the facility in 1998, shortly after acquiring Sachs Bicycle Components. Back then, the 17,000m2 (183,000sq ft) building was primarily used for the production of internally geared hubs. That aspect of the business has since moved overseas so it's now home to about 180 employees and serves as SRAM's main mountain bike and road drivetrain development resource – in fact, most of the new SRAM Red group was designed and engineered here, not in Chicago.

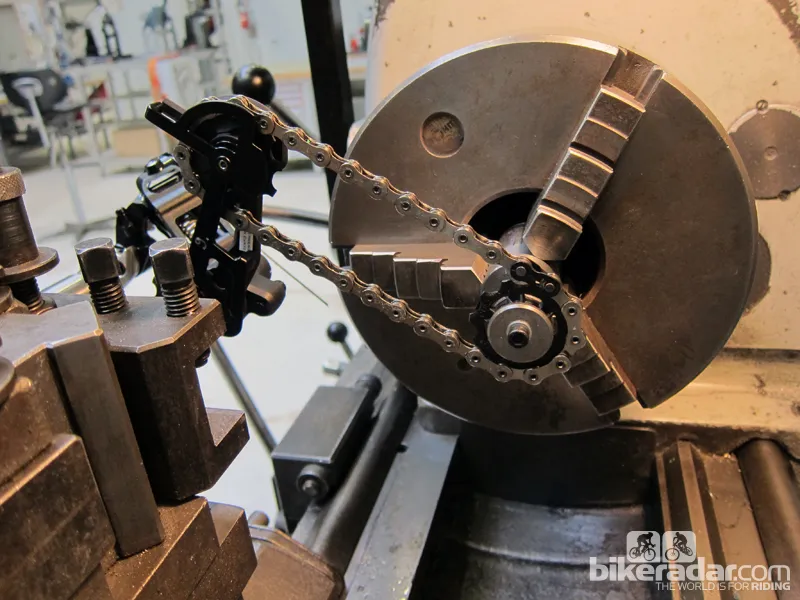

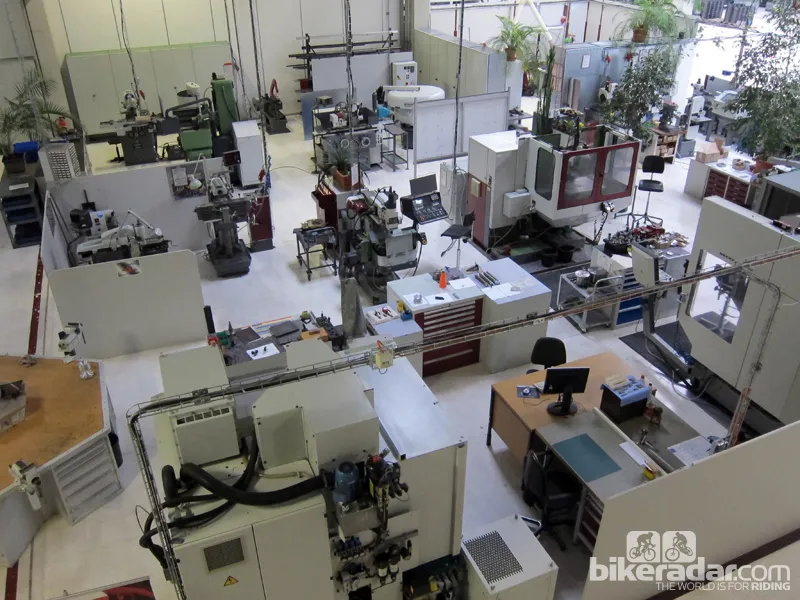

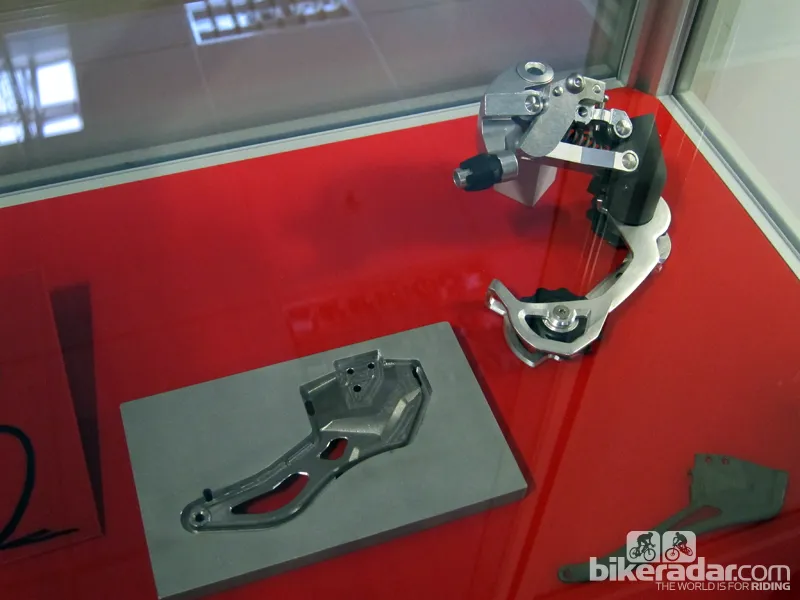

The company's engineers don't just design new components here, however. There's a full machine shop and prototype facility to build new concepts in-house as well as a sprawling test area for both validating ideas and confirming the durability of production components. Virtually every major drivetrain component SRAM makes can be tested here, including internally geared hubs, traditional derailleurs and shifters, chains and complete wheels.

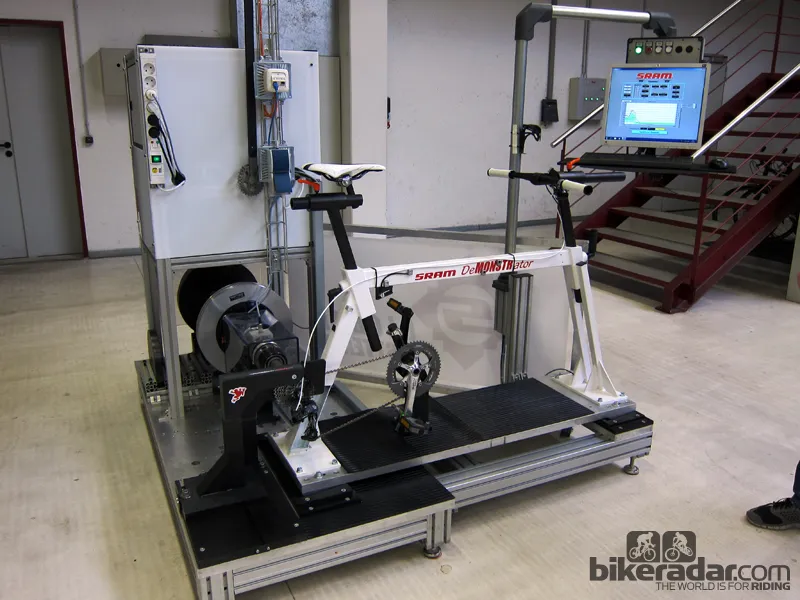

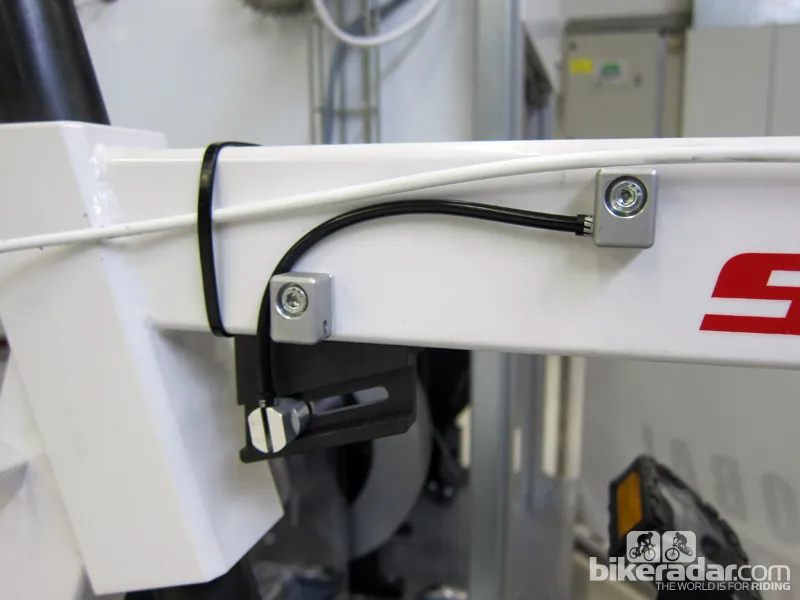

Much of the test equipment is as you'd expect: rotating machinery to pack on mileage with computer controlled shifts, environmental chambers for torture testing components in extreme conditions, and various pieces of hydraulic gear for measuring fatigue life and failure points. Also included in the inventory, however, is a bike set up with a mountain of data acquisition gear (SRAM engineers not only measure empirically how often people tend to shift but even what gears are used most often) plus a high-speed camera to better gauge shift performance.

Unable to load media

Drivetrain testing at SRAM's Schweinfurt headquarters

Recently, SRAM have been converting part of the Schweinfurt facility into more of a support hub, with the creation of a new Dealer Services Direct base to serve the German, Dutch, French, British and Scandinavian markets. Shops can send items directly to Schweinfurt for service when needed and there are six benches and five mechanics on duty at any given time, plus a dedicated parts inventory (we even spotted a damper for an old RockShox Duke Race).

"If we have spares, we'll work on it," SRAM European MTB PR and communication co-ordinator Simon Cittati told BikeRadar during our visit. According to Cittati, DSD mostly services forks and brakes in about a 50/50 split – shops are generally reasonably comfortable handling the rest on their own.

The final main portion of the building is dedicated to SRAM's European race shop – the base of operations for SRAM's road, mountain and cyclo-cross sponsorship and event support. Team and athlete inventory is staged here before shipment and there's an enormous bay big enough for SRAM's gigantic race support rig. Prior to major outings, SRAM's support staff will dock the trailer here – indoors – load, unload and reconfigure as necessary, and then head back out the door.

All in all, there's a lot more going on inside than the modest exterior would suggest. SRAM are still a US company but after spending some time in Schweinfurt, it seems that it'd be safe to say that they're a German one now, too. Check out our image gallery for a tour of the facility.

The courtyard of SRAM's drivetrain development facility in Schweinfurt, Germany includes a pump track