In the world of professional road racing, tubeless tyres remain a novelty. The vast majority of pros ride traditional tubular tyres glued to tubular-specific rims, and while there have been notable instances of pros racing on tubeless, there’s been little evidence of a sea change in attitudes towards tyre technology.

It feels like we’ve been on the verge of road tubeless going mainstream on the consumer side for years. Every mainstream wheel maker now offers tubeless versions of its wheels and almost every big player in tyres has in some way jumped on board, albeit with varying levels of commitment.

This year, however, we’ve seen racers at the highest level of the sport competing on tubeless tyres: Fabio Jakobsen took stage four of the Tour of California and his Deceuninck–Quick-Step team has lined up at a number of races with bikes wearing Specialized’s new tubeless Turbo RapidAir, a tyre first spotted at the Tour Down Under on none other than Peter Sagan’s bike.

Alexander Kristoff triumphed at Gent–Wevelgem on tubeless Vittoria Corsa tyres, and a number of his UAE Team Emirates colleagues were riding the same setup at this year’s Tour de France.

Several teams seem to be dabbling with the technology, and some have dived in headlong. Elite women’s squad Canyon//SRAM and men’s Continental outfit Canyon dhb p/b Bloor Homes are both racing tubeless, the former on Schwalbe’s newly-revised Pro One, the latter on Maxxis Padrone tubeless tyres.

I asked a number of key players in the world of wheels and tyres whether tubeless will replace tubulars in the pro peloton, and the responses I’ve received suggest that while the industry is strongly behind tubeless and believes in the technology, we’re some way from a tipping point in the upper echelons of racing.

Standardisation across the industry may change that very quickly, but that remains to be seen. The bodies responsible for overseeing the wheel and tyre industry — ETRTO (European Tyre and Rim Technical Organisation) and ISO (International Organization for Standardization) — are in the process of issuing updates to the regulations governing the sale of tubeless tyres.

With potentially greater clarity for consumers and far fewer compatibility issues between different brands of tyre and wheel, this could be a very significant moment for tubeless, paving the way for more widespread adoption of the technology.

Thanks go to Continental, Hunt, Mavic, Schwalbe, Specialized, SRAM and Stan’s NoTubes for their assistance in researching this piece.

What’s the point of road tubeless anyway?

The purported advantages of tubeless are well-trodden ground, with manufacturers claiming lower rolling resistance and citing the convenience of having punctures self-heal when using sealant.

Without a tube, pinch flats cease to be an issue, so it’s possible to run lower pressures than you would otherwise, increasing comfort and grip.

Tubeless technology has taken over almost completely in mountain biking, at least in enthusiast circles. Inner tubes aren’t likely to be going anywhere at the lower end of the market where marginal performance gains take second place to everyday simplicity.

Tubeless has also made considerable inroads in the worlds of gravel and cyclocross, where tyre widths in the 32 to 50mm range dominate and the advantages remain clear-cut.

The case for road tubeless is more nuanced. While the same theoretical advantages apply on the road, it is debatable whether the average rider will realise those advantages.

Those who are plagued with punctures or who desperately seek lower pressures have a clear motivation to go tubeless, but if a conventional clincher setup satisfies your everyday riding needs, the case for sloshing sealant around is weaker.

The pitfalls of tubeless gone awry are enough to put many riders off, but the balance could tip in tubeless’ favour if new standards can alleviate concerns over mounting and seating tyres, as well as actual safety.

Tubeless really is faster

Lower rolling resistance is clearly an advantage that matters to racers, and there seems to be consensus across the industry that the best tubeless tyres really do roll faster than the best tubulars (and the best conventional clinchers).

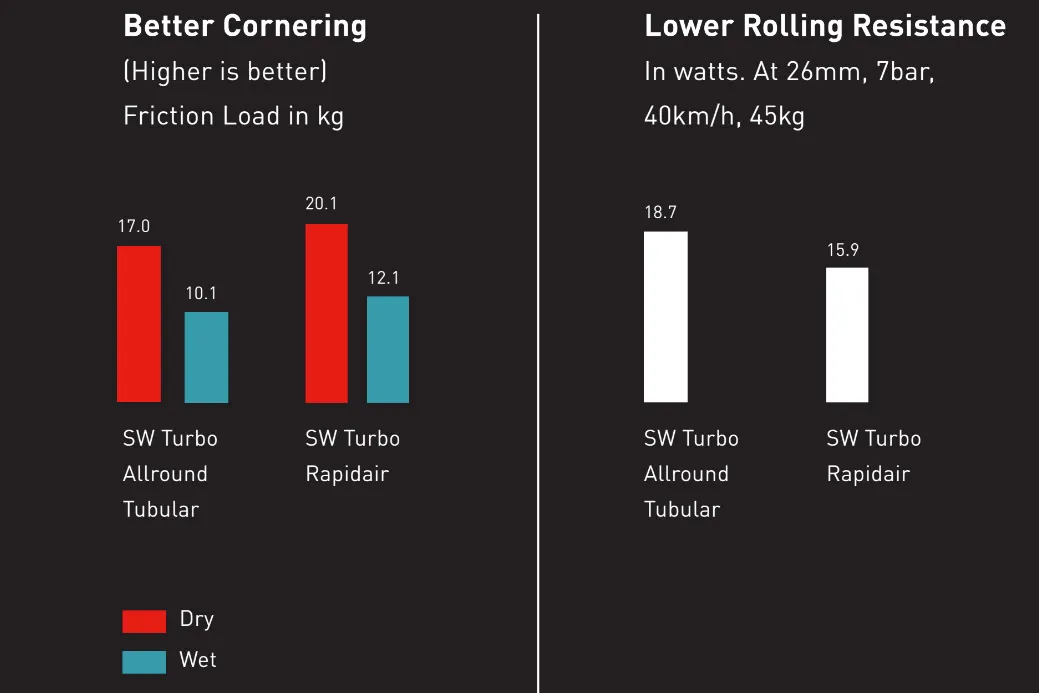

Specialized, for example, claims its newly launched Turbo RapidAir tubeless race tyre saves 2.8w at 40km/h against its tubular counterpart (in lab conditions with a 45kg load, at 7 bar / 101.5psi) while Schwalbe’s new Pro One is claimed to best the Pro One HT tubular by an astonishing 17 watts at the same pressure and the slightly higher speed of 45km/h. (The load wasn’t specified.)

And if you head to Bicycle Rolling Resistance and do some side-by-side comparisons, the tubeless options invariably win out.

What constitutes an apples-to-apples comparison is a little murky, however; particularly when pitting technologies as fundamentally different to one another as tubulars and tubeless.

The construction of the tyres is completely different and indeed tubulars and tubeless tyres of the same nominal width, from the same manufacturer, may measure up quite differently when mounted.

There are other variables too. Jan Heine of René Herse Cycles/Bicycle Quarterly — himself a long time proponent of super-supple wide tyres — isn’t anti-tubeless, but he is convinced that the use of sealant in tubeless tyres largely negates the supposed reduction in rolling resistance they offer.

Bicycle Rolling Resistance’s Jarno Bierman doesn’t agree. In a report published in 2014, he found that 30ml of sealant in a 25mm road tyre increased rolling resistance by just one watt at 36km/h — a penalty far smaller than the typical advantage tubeless tyres hold over their clincher and tubular counterparts.

For what it’s worth, when BikeRadar ran its own performance tyre lab tests with help from Wheel Energy back in 2017, the original tubeless Schwalbe Pro One trounced all of its standard clincher competitors with 25ml of sealant on board.

There is one huge caveat to all of this: we’re still talking about a tiny difference in performance here. Rolling resistance matters, but at bike race speeds it’s a small part of the overall picture, with the vast majority of a rider’s energy expended fighting wind resistance.

On that front, SRAM’s Geoff Przekop raises an interesting and perhaps rather overlooked point: “We have consistently measured that clinchers [including tubeless] are more aerodynamic than tubulars, starting way back with our Firecrest development more than 10 years ago.

“Of course, the specific results will vary depending on the individual rim and tyre designs, but we see very few exceptions to this trend when testing. Specifically, clincher tyres tend to outshine tubular tyres as yaw angle increases above 10 degrees — potentially due to the cleaner transition they exhibit between tyre and rim outer diameter.”

Ultimately, a pro’s job is to win races though, so if there’s a real performance gain — however marginal — they’d be a fool not to embrace tubeless, wouldn’t they?

Will tubeless replace tubulars in pro racing?

Tubeless tyres have been popping up at races since the mid-2000s. Michelin went so far as to introduce three tubeless road tyres for pro use back in 2004, but it appears the project was shelved because they were never sold to consumers.

Along the way, various lower-tier pro teams have ridden tubeless tyres and, much more recently, there have been some notable high-profile victories at the very top of the sport, such as Jakobsen's win at the 2019 Tour of California on tubeless and Kristoff's victory at Gent–Wevelgem on 25mm Vittoria Corsa Graphene 2.0 tyres.

Kristoff might have gone a little too hard on the Kool-Aid, however. Flying in the face of conventional wisdom, which sees most riders on tyres at least 28mm wide if not bigger, he rather optimistically stuck with the same rubber for Paris–Roubaix and saw his ambitions crushed by a series of unfortunate punctures, a demonstration of the fact that sealant can only do so much.

Compared to amateur riders, professional cyclists face a completely different set of pressures when it comes to tyre choice. Mechanical support is available whenever it’s needed in a bike race, but every puncture is a potential race-loser, so reducing the frequency of flats overall is paramount.

In theory, you can inject sealant into tubular tyres and gain one of the advantages of a tubeless setup. Indeed some teams have certainly done so for puncture-heavy races such as Paris–Roubaix, but tubulars have never been made with sealant in mind.

There’s no way to remove dried-out sealant from a tubular and, depending on the precise construction of the tyre, (some have an inner tube, some do not) sealing may be ineffectual anyway.

Safety is of course a major concern for pro teams, too — while tubulars are susceptible to rolling off rims if improperly glued, tubeless tyres are liable to blow off the rim if either the tyre or rim is out of spec or damaged.

Pro cyclists for the most part tend to err on the side of caution when it comes to equipment choices, at times resisting change. Remember how long it took for pros to use disc brakes? (Many still don’t.) And how, until very recently, the more old-school Euro teams routinely raced on 23mm tyres inflated to approximately one million psi, despite a growing consensus that slightly wider tyres (and slightly lower pressures) might actually be faster in the real world.

There’s no question that pros are paying more attention to tubeless, however. According to wheel maker Hunt’s Ollie Gray, the Canyon dhb p/b Bloor Homes Continental team voluntarily moved from an 80:20 tubular:tubeless split in 2017 to being 100 percent tubeless for the 2018 season.

He’s realistic about the technology though, acknowledging the fact that riders who puncture seriously on tubeless aren’t able to ride the flat tyre as they would with a tubular because there’s a danger that it might come off the rim.

Schwalbe’s Felix Schäfermaier thinks this will soon be less of a concern because tyres conforming to the incoming standards “will stay on [in the event of a puncture]”.

Gray also notes that tubulars are still the best option for pro cyclocross racers, but that “for us mere mortals… there are essentially no drawbacks to road tubeless” it’s “the right choice for 99 percent of purposes”.

There is a sense that tubulars have peaked, but that’s not to say they’re going anywhere anytime soon.

Other than Stan’s NoTubes, the brands I approached all continue to produce tubular wheels or tyres, and some of them are still making incremental improvements to their tubular ranges.

On the other hand, Specialized’s Oliver Kiesel and Mavic’s Maxime Brunand are notably frank about where their respective brands’ energies are now focussed. In essence, they say there’s no new investment being made in tubular tech; tubeless is where it’s at.

Kiesel is keen to emphasise that the ultimate goal is performance. His goal is not to promote tubeless, it’s to ask “what makes our riders faster?”

All of the brands I asked think that tubeless will become more common in the pro peloton, but even those who are heavily invested in the tech aren’t predicting an immediate takeover.

Continental’s Jan-Niklas Jünger believes that rather it will “give [riders] another option” while Schwalbe’s Schäfermaier is more categorical, saying of the pros: “they will change”.

Standards are coming

One of the biggest hurdles to wider adoption of tubeless road tyres has been a lack of standardisation across the industry, something our then tech ed James Huang lamented as long ago as 2008.

While you can generally count on consistent results if you stick within a given brand’s ecosystem (e.g. running Zipp tyres on Zipp rims), there’s no guarantee that a random tubeless road tyre bought in a bike shop will work well with the ‘tubeless-ready’ wheels on your bike.

In this context, working well means mounting easily on a rim, seating without undue trauma and remaining on the rim without burping or blowing off in the course of normal riding.

All that could be set to change as a major update to ISO 5775 — the international standard which governs bicycle tyre sizing — is due. According to Schwalbe’s Felix Schäfermaier, a new ETRTO standard has already been agreed and issued to manufacturers, with the ISO update expected to follow soon.

Major players in the industry have been working together to hammer out a set of definitions and norms that work for everyone and improve the situation for the people actually spending money on wheels and tyres. An established standard is a very significant milestone in the history of road tubeless.

(For some insight into the wrangling behind the scenes this has involved, tyre nerds may enjoy this frank open letter penned by Morgan Nicol of Challenge Handmade Tyres earlier this year.)

Talk of new standards sometimes provokes rending of garments in the public galleries, but this isn’t some vapourware bottom bracket design or a new axle that’s pointlessly very slightly wider, it’s potentially a fundamental re-writing of the rules that underpin tyre sizing and labelling, and the way that rims are designed to interact with them.

According to Stan’s President Mike Bush: “the goal of the standards is not to limit innovation but to create common ground with respect to what ‘tubeless’ or ‘tubeless ready’ really mean, how to measure and mark product to ensure compatibility, and generally ensure the end users have safe product to ride.

“The current product on the market is often safe and effective but given the myriad ways to approach the problem, not everything works together as it could or should.”

It’s clear that road tubeless is here to stay, but seemingly as ever, the takeover remains just over the horizon.