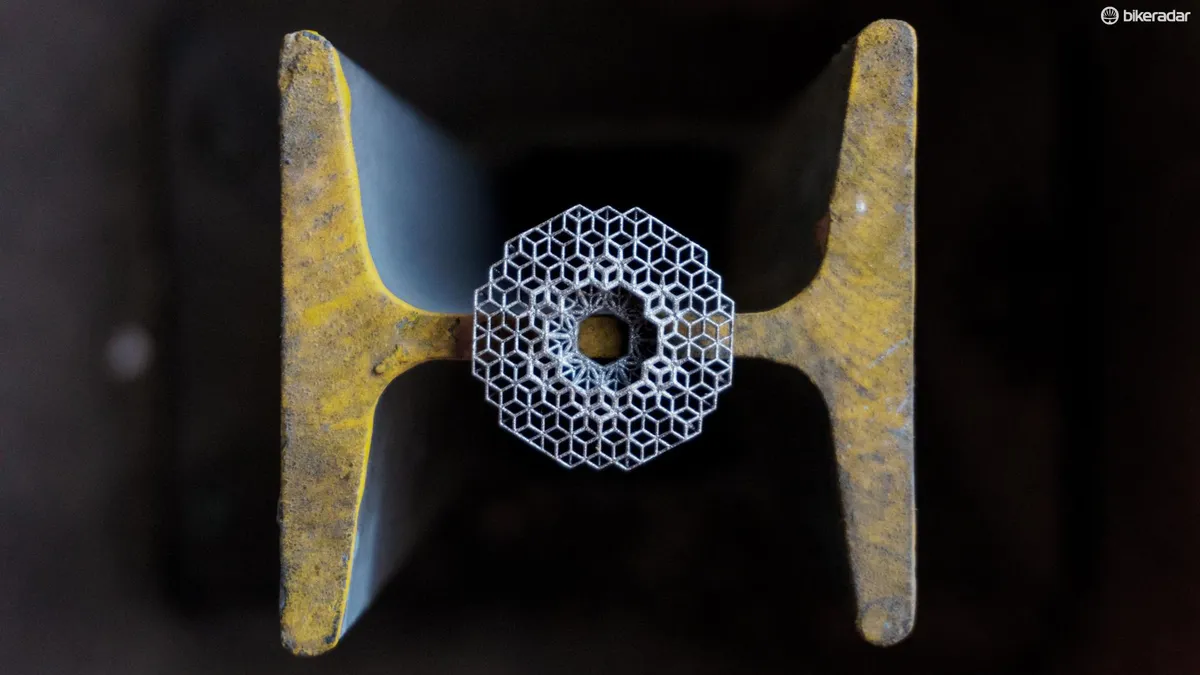

This $140 3D printed titanium top cap is almost certainly the most outrageously expensive option on the market.

However, the heady cost does not diminish my enthusiasm for this oh-so-lovely tidbit that, as well as looking nice, I think may just give us a glimpse into the future of manufacturing.

The top cap is the first production-ready product from Addition Performance Components.

The new brand is the brainchild of Spencer Wright, an alarmingly prolific young man who is an expert in industrial design, additive manufacturing and a former custom bike builder.

He also manages an incredibly interesting newsletter for “people working on real problems in the physical world” that is well worth subscribing to.

Designed in nTopology Element Pro — a piece of fancy CAD software for optimising and designing lattice-based structures that Spencer helped design — the cap is printed from titanium 6AL4V using laser metal powder bed fusion.

As fans of drilium love to quip, there’s nothing lighter than a hole. Given this top cap is more hole than not, it should come as no surprise that it comes in at a feathery 4g.

The top cap has that typically matte and slightly rough texture of 3D printed titanium, which feels great in the hand — thumbing it while it has sat on my desk for the last few weeks has yet to grow tiresome.

I don’t think anyone, not least Spencer, is going to claim that this top cap does the job of being a top cap significantly better than a regular one.

Instead, it’s better viewed as a lovely, albeit expensive, design exercise that may just be a glimpse into the future of bicycle construction.

Where else may this technology be used?

Alongside the top cap, Spencer has also been working on a stem that is constructed in roughly the same manner. We actually posted about this stem on our Facebook page back in 2017 and the reaction was… mixed.

Speaking more generally, I can see this lattice-based construction becoming increasingly used on bicycles and in wider applications as It allows for super strong structures that use material very efficiently.

With 3D printing technology also becoming more accessible by the day, it may even reach a point that producing parts in this way may be cheaper than traditional methods.

Reynolds has certainly been exploring the possibility of using 3D-printed lattice structures for frame parts in its own investigations as well as in collaboration with Mirada Pro. I have no doubt that other mainstream manufacturers are too.

In the meantime, I will continue to admire Spencer’s work and watch Addition Performance Components very closely.