As well as being an enormous physical challenge for the riders, Grand Tours pose an equally large logistical task for the teams and their support staff.

For three weeks, the work practically never stops for chefs, mechanics and soigneurs.

Bikes and team vehicles need to be cleaned and maintained every evening, and riders need to be cared for to extract maximum performance.

Everyone also needs to be fed multiple times per day, of course.

After stage 18 of the 2023 Giro d’Italia, we had the opportunity to take a peek behind the curtain at the Movistar Team hotel.

While the riders recovered from a long day in the mountains and prepared for the next stage, work continued for the rest of the team.

We also spoke to the team’s principal directeur sportif, Max Sciandri, about how the team organises itself and the riders to extract the maximum performance possible from the unit.

Clean and check everything

After a transfer from the stage finish to the team hotel of about an hour and a half, there’s still plenty of work to be done.

One of the main jobs for team staff post-stages is to clean and maintain both the team bikes and all of the team vehicles.

Cleaning the bikes is essential not only for looking professional, but also so the mechanics can give the bikes a once over for any problems or potential issues.

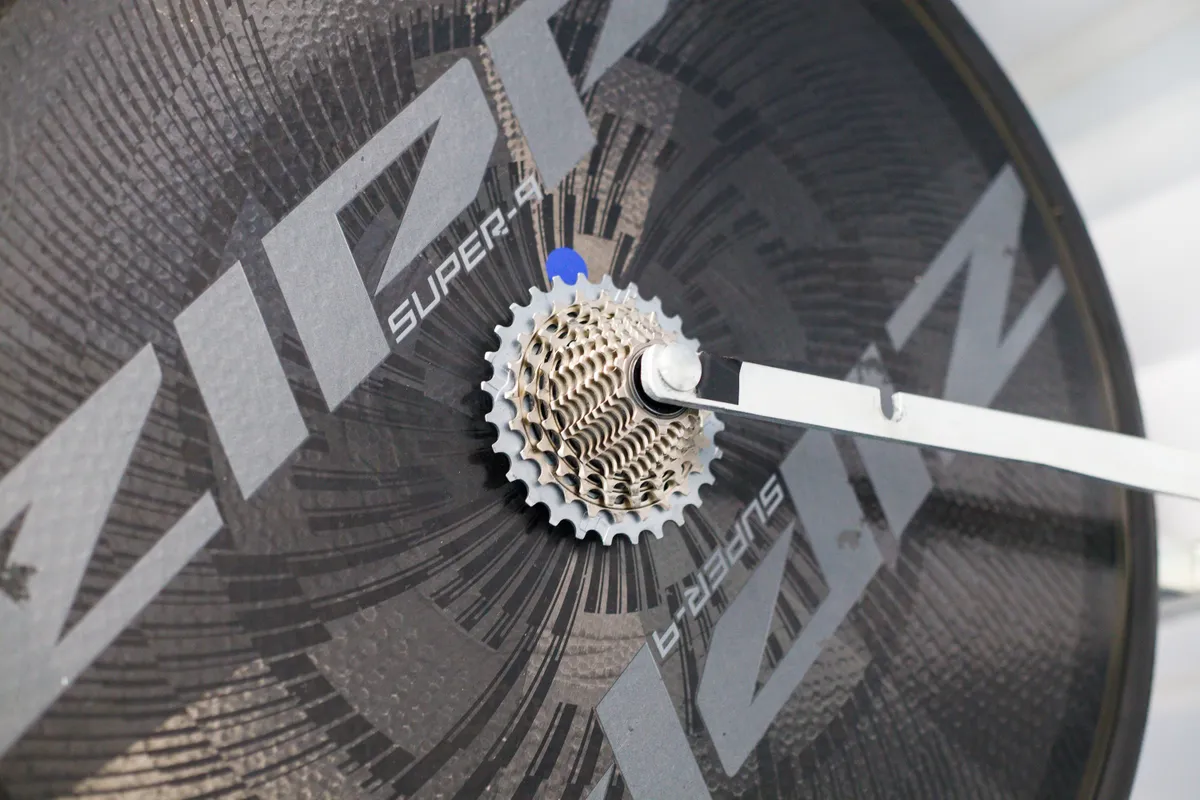

Depending on the stage profile for the following day, the mechanics will also swap gearing sizes (typically by changing the rear cassette), or fit different tyres, if the parcours demands it.

Given tubeless tyres have largely taken over in the pro peloton these days, it was also no surprise to see mechanics popping tyres off rims to check sealant levels and give wheelsets a top-up, if required.

Though it might seem excessive to your average cyclist, who perhaps cleans their bike once a week or so, Sciandri points out “this is the pinnacle of the sport”, and the team doesn’t want to leave anything to chance.

While most home mechanics make do with a standard track pump or tubeless inflator, the Movistar Team mechanics have an air compressor to make things as easy and efficient as possible.

As you’d expect, the mechanics’ truck was full to the brim with expensive road bikes and wheelsets, from the Canyon Aeroad CFR to the Ultimate CFR climbing bike and Speedmax CFR Disc TT bike.

Teams need to be prepared for almost any eventuality, and are often a long way from their service course. This means all spares need to be carried on the road.

After washing, the individual bikes are left to dry on a rack outside of the mechanics’ truck before being stowed away safely for the night.

The team bus also gets a clean every night.

At this Giro, Movistar Team had one of its older team buses for the riders. Granted it was no National Express coach, but it wasn’t quite the Team Sky Death Star of legend either.

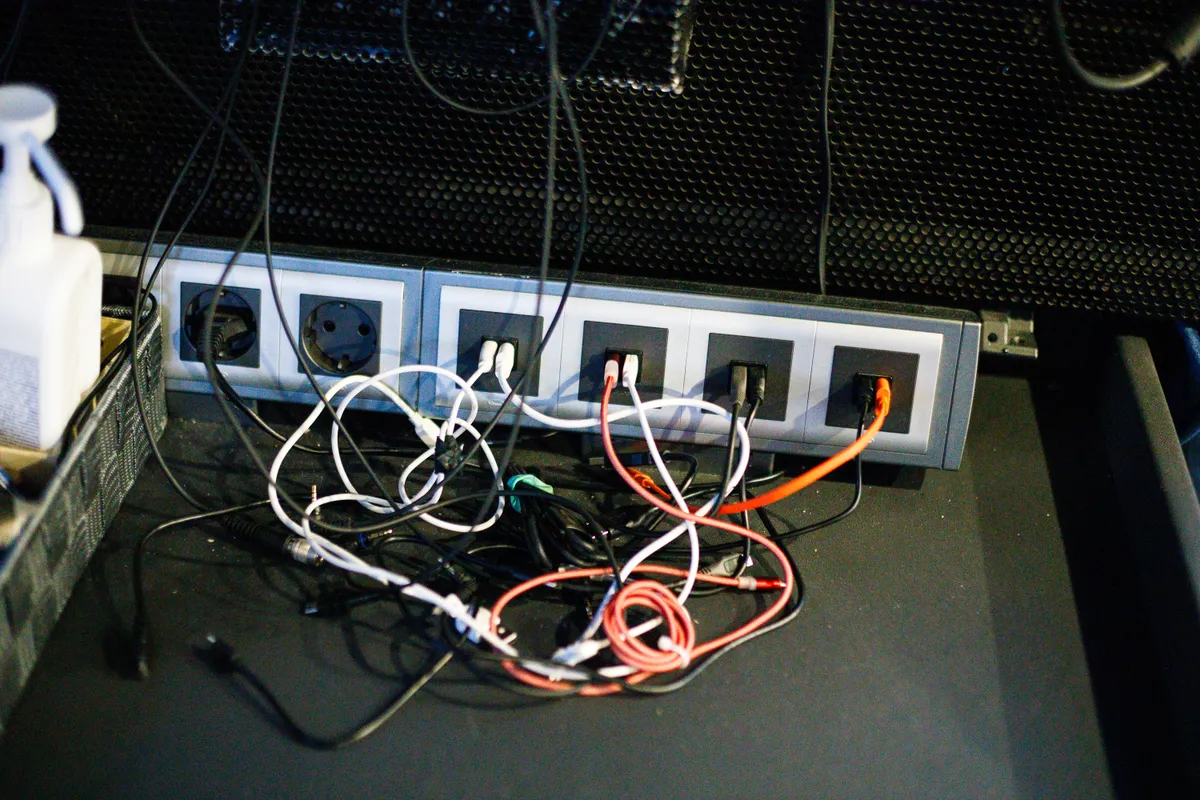

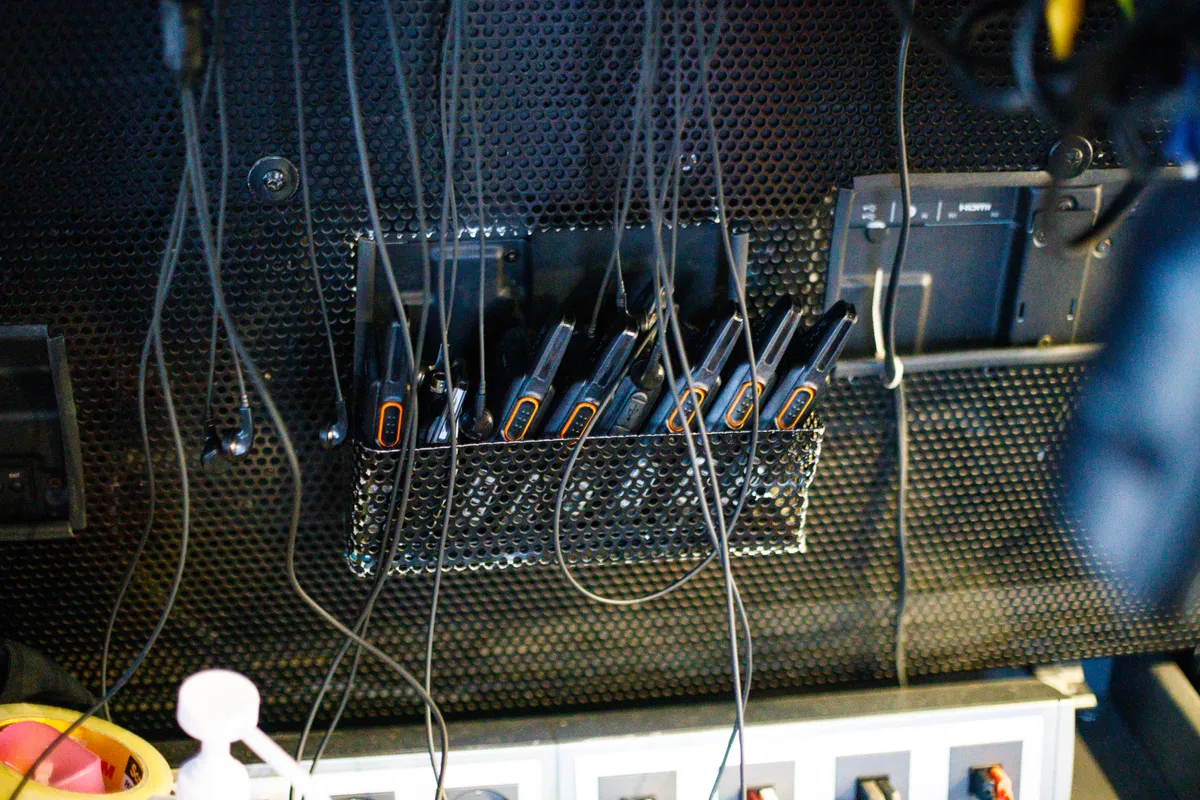

Still, though, it seemed a perfectly comfortable place to get to and from team hotels and stage starts/finishes. It had all the features you’d expect, such as comfy chairs, showers, places to charge devices and store kit and, of course, a coffee machine.

Speaking about his management style, Sciandri says “every director is different, but I trust my departments… and I let them work. I oversee stuff, but I don’t interfere in their jobs.”

Likewise, when it comes to equipment choices, Sciandri notes his many years as a professional rider and sports director give him a wealth of experience that he’s always happy to offer to riders.

At the end of the day, though, “it’s their [the riders'] choice – they have all the information on hand to know what gear to use”, so unless riders ask specifically for advice on the topic, he’s happy to leave them to make their own decisions.

Counting calories

Like an army, a cycling team rides on its stomach.

Given this, the team chef, Lorenzo Pajares, and kitchen truck are just as important as the mechanics and their truck.

The challenge for a cycling team chef is to make food for the riders that is appetising, easily digestible and provides the right nutritional balance to fuel and recover from the enormous demands of Grand Tour racing.

With the widespread adoption of power meters across the pro peloton, it’s much easier to calculate accurately how many kilojoules riders are burning during each stage.

From this, teams can work out how much the riders need to eat to recover from each stage and fuel for the coming days.

The kitchen truck also carries another coffee machine (you can’t have too many of these when you’re a European cycling team), plus a fridge with beers and a bottle of sparkling wine, just in case the team has any wins to celebrate (such as Einer Rubio’s win on stage 13 of this year’s race).

When we spoke to Lorenzo, at around 7.30pm after stage 18, he was busy preparing dinner for the riders.

The riders, Sciandri notes, would have already had a recovery drink and some food on the bus back to the hotel, post-stage (typically some rice with some lean protein, such as tuna).

Because it’s a Spanish team, the riders prefer to eat dinner fairly late, around 8.30pm to 8.45pm. Staff, though, Sciandri said, wouldn’t be eating until 9.30pm.

The next day

For Sciandri, one of the most important evening tasks is to check plans for the following stage.

Planning mid-race feeding points, for riders to take food and bottles from team staff at the side of the road, is also crucial because riders won’t always be able to go back to the team car in the race convoy to get what they need.

There was also, Sciandri said, “another hour-and-a-half transfer to stage start” to consider the following morning, meaning there would be another early start to the day for the team.

Like a travelling circus, the team would also move everything on to the next hotel too – as would the other 21 teams in the race.

Though the racing unsurprisingly dominates the headlines, the amount of work and planning that goes on behind the scenes of a Grand Tour is staggering.