Here at BikeRadar, we love all things bike, but there’s always going to be a component, part or problem that particularly irks us.

Our mountain bike tech gurus have picked their pet hates and explained why they think these shouldn’t still be problems we have to deal with.

From mud that shouldn't be sticking to our bikes' paintjobs to tyres and tubes that are still susceptible to punctures, and a plethora of confusing ‘standards’ that make swapping components almost impossible, we want to see improvements across the board.

If you think bikes are just boring these days – recall the meme 'it looks like a Session' – or you think they’re just too hard to work on, you’re not alone.

Keep reading to find out more.

Alex Evans: blighted by punctures

Punctures have haunted me since I started riding just over 25 years ago.

Despite impressive advances in technology elsewhere, tyre and rim manufacturers still haven’t found a foolproof way of keeping mountain bike tyres inflated.

Granted, balancing weight, durability and – crucially for mountain bikes – tyre grip and feel is tricky, but none of this should preclude keeping air where you want it.

But bike brands and tyre manufacturers don’t make life easy for themselves.

All too often, descent-focused enduro bikes or electric mountain bikes are fitted with lightweight rubber that's prone to slashes, pinches and getting rolled off the rim.

Of course, chasing headline weight figures is great for marketing, and maybe speccing lighter tyres reduces the bike’s purchase price.

In the long run, though, they’re doing their customers a disservice, if those customers need to replace a punctured tyre with more appropriate rubber at a hefty cost.

Brands seemingly continue to struggle with design too, adding material where it isn’t needed and taking it away where it is. Some tyres have thick, supportive, puncture-resistant sidewalls, but the rubber beneath the tread pattern is thin and quick to slash.

Others have a more balanced construction, but I’ve still slashed, pinched and destroyed countless tyres like this.

Inner tubes are no better. Illogically, their extra material doesn’t enhance puncture resistence – running tubes is a sure-fire way to flat.

Touted as the puncture panacea, tyre inserts are claimed to all but stop air loss, help you run lower pressures, reduce carcass deformation and protect your bike’s rims.

In my experience, they don’t.

Yes, they reduce pinch flats, but tyres are still prone to slashes, and don’t get me started on how bad inserts feel when you’re running lower pressures.

Tubeless sealant also sucks.

While I’ll agree its inefficiency varies, if the hole is big enough – usually more than 2mm – that runny liquid is just getting thrown all over you and your bike rather than plugging the rupture.

In my eyes, tyres that rely on pressurised air to work aren’t fit for purpose.

If brands diverted some of their R&D money away from fancy electronics and carbon fibre to create a truly un-puncturable tyre, they’d have hordes of people queuing up – me included – to give them money.

Luke Marshall: mud-repelling paint

I’m going off on a bit of a tangent, casually meandering into wishful-thinking territory.

What could possibly need improving in the mountain bike industry? I’m not here to throw shade, just to spice things up with a whimsical wish – what if there was a paint that could magically ward off mud?

In the UK winter, cleaning bikes is almost like a second job. Wouldn't it be brilliant if that became a thing of the past?

Here’s my dream scenario: your bike comes out of a muddy adventure looking as clean as if it just had a spa day. A little bounce to shake off the loose bits, a spritz for the drivetrain, a quick wipe-down and boom – good as new.

Sure, there are products claiming to do something similar, but what if this mud-repelling feature was ingrained in the paint or surface treatment itself – a forever kind of frame-finishing property that didn't fade away?

Still, we shouldn’t forget the eco-friendly properties of this magic chemical. It would, of course, be non-toxic, biodegradable, environmentally friendly and sustainable.

Plus, it would prevent mud from playing messenger for potential tree diseases to prevent the spread around our favourite riding spots.

I can't help but feel a tad sorry for the traditional bike-cleaning brands we’d no longer need, but hey, in the world of tech evolution, there are winners and losers.

So, here's my dream – clean bikes for everyone, for life, without leaving a trail of environmental guilt. Not too much to ask, right?

I’ll get my bucket!

Tom Marvin: make standards standard

This isn’t the first time I’ve gone off on a rant about this, but my absolute pet hate with the bike industry is the never-ending proliferation of standards.

Recently, I’ve built a few bikes from the frame up, using some new parts but mostly odds and sods found in my garage.

This has led to last-minute phone-a-thons around Bristol’s bike shops trying to find parts, mismatched bolts and adaptors that hurt my perfectionist brain. Then there are multiple assemblies and disassemblies as I try and get things fitted in the right way to have a working bike.

I’m far from a natural mechanic and, truth be told, anything where I have to swing an Allen key is a chore rather than something I actively enjoy.

A large part of this is because the bike industry seemingly cannot agree on standards.

Why is it that to fit a crank, I need to consult a table where the grid is denoted in codes and measurements?

There are three different spindle diameters, multiple ways of squeezing a bottom bracket into a frame and a whole host of marginally different tools required to do so.

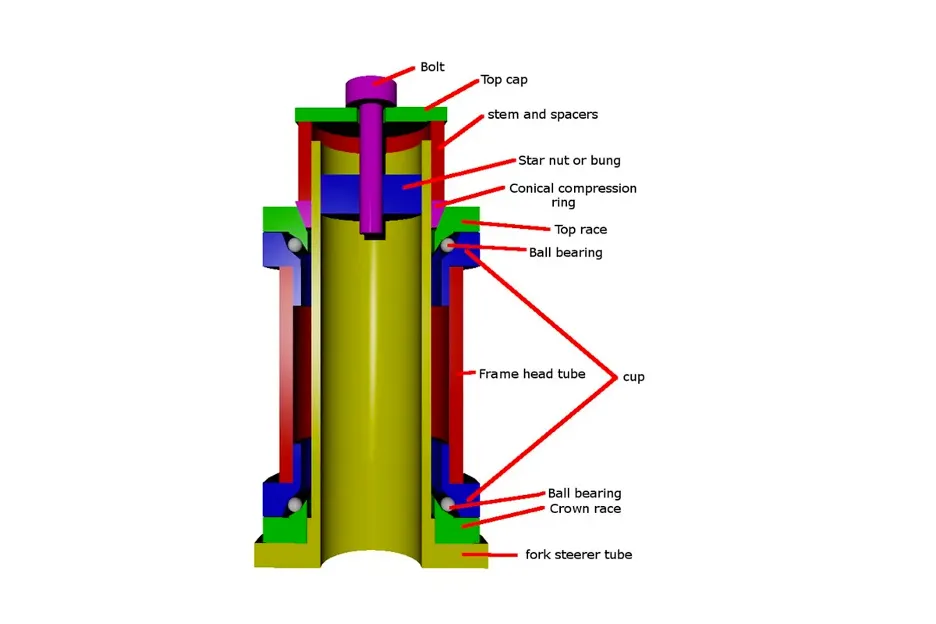

Why do the likes of Cane Creek and Hope need to supply a confusingly vast array of headset bearings, cups, top caps and wedges?

Why, even, are there four – yes, FOUR, different seat-tube diameters?

Each manufacturer no doubt claims to believe its chosen ‘standard’ is the best for the job – I’m not here to argue that that’s not the case.

However, if I was in charge, there would be one headset standard (I don’t care if your ZS52, LS, XYZ is 1.2 per cent better in the lab), cranks (and chainrings) would fit on bikes without needing a doctorate in chainline geometrics and everyone would stick with 34.9mm seat tubes.

This proliferation does not make our lives easier and it does not make our bikes appreciably better.

Bike shops are left unable to help because it’s impossible to stock every variation of every component, contributing to the demise of the bricks-and-mortar shop.

The result is, my blood pressure goes through the roof. The only benefit I can see is it drives plenty of traffic to our fabulous complete guide to bottom brackets and ultimate guide to headsets (two articles that simply should not need to exist).

The one thing the industry has got right? The Universal Derailleur Hanger.

Tom Law: modern mountain bikes should have more personality

Is it just me, or are so many new bikes really boring? It has genuinely been a while since I was super-excited about a newly released bike.

Yes, I’m in a very privileged position where rarely a week goes by without a press-release being shared around the office or a new bike being discussed for a video on our YouTube Channel. One could argue it's easier for me to go snow blind from looking at bikes day in, day out.

But the last time I looked at one and said, “Wow, that’s really cool!”? It’s been a while.

Canyon’s GeoBend springs to mind, as does the Scott Endorphin shown at EuroBike last year.

What do these bikes have in common? They are concept bikes. Bikes we, the public, can’t buy.

As a car buff, as well as a mountain bike nerd, I love seeing concepts that stand out a mile off, offer something new in terms of styling, or just look cool for cool's sake.

I just find so many bikes nowadays are… clinical – devoid of any personality.

We read the claims of 10 per cent stiffer here, 7.99 per cent lighter there, but I want to hear more about how the lines have been inspired by a wind that blows through a mountain range, or sun glistening through an area of outstanding natural beauty.

Where are the flowing, artistic shapes that marked out the likes of the original Ibis Mojo, Rocky Mountain’s ETSX or any number of Yeti’s DH prototypes from the mid-2000s?

So many bikes are just cookie-cutters of one another. Three bikes I threw a leg over in 2023: the Specialized Epic, Canyon Lux and Rocky Mountain Element would, if painted purely black, be practically indistinguishable from one another.

So please, bike brands, bring back some style and individuality to the world of mountain bike design. We’ve all had enough “Looks like a…” comments to last a lifetime.

Will Soffe: make MTBs easy to work on

Modern mountain bikes boast amazing technology and inventions that make life easier and more rewarding for the rider. But what about when those bikes need servicing, or something breaks?

Working on your mountain bike is a hugely rewarding pastime.

Whether you’re doing the basics such as fixing a puncture or changing your bottle cage, or fettling technical components such as the inner workings of a suspension fork or rear hub, working on your bike forms a bond between rider and machine, and can create joy and contentment.

So what is the bike industry doing to foster this special time spent getting intimate with your steed? Well, in my opinion, not enough.

I want to see servicing and repair planned into the heart of bike design. At the moment, while many bikes show incredible user-friendliness for the rider, they don’t exhibit the same forethought and planning toward the bike mechanic.

I would like to see the menace that is headset cable routing end, and ideally a return to more servicing-friendly external routing, where possible.

Yes, yes; I know this subject has been done to death, but honestly, spraying hydraulic fluid from a disconnected brake hose over the inside and outside of your frame (and your workshop) is enough to make even the most seasoned mechanic wince.

Please could it become the accepted norm that all bolts used to tighten a loose headset are the same size?

If the top-cap and stem-clamp bolts all took the same tool (a 5mm Allen hex for example), it would make this routine job just a little bit more satisfying.

And brake manufacturers, please can we see a lovely threaded bleed port on the top of all hydraulic brake levers?

There is an art to refitting a bladder membrane below the reservoir cap on a freshly bled brake, but honestly, could we just do without the hassle and use a threaded syringe instead?

Not enough care fitting that cap and the bike comes off the uplift with spongy brakes – and ain’t nobody got time for that!

So please, bike manufacturers, take note: think of the bike mechanics when you design MTBs, we will all thank you for it.