Hookless rims have been a topic of much debate in recent years.

Manufacturers of carbon rims are increasingly adopting hookless rims, citing performance benefits such as lower weight, improved aerodynamics and reduced manufacturing complexity (and therefore lower production costs).

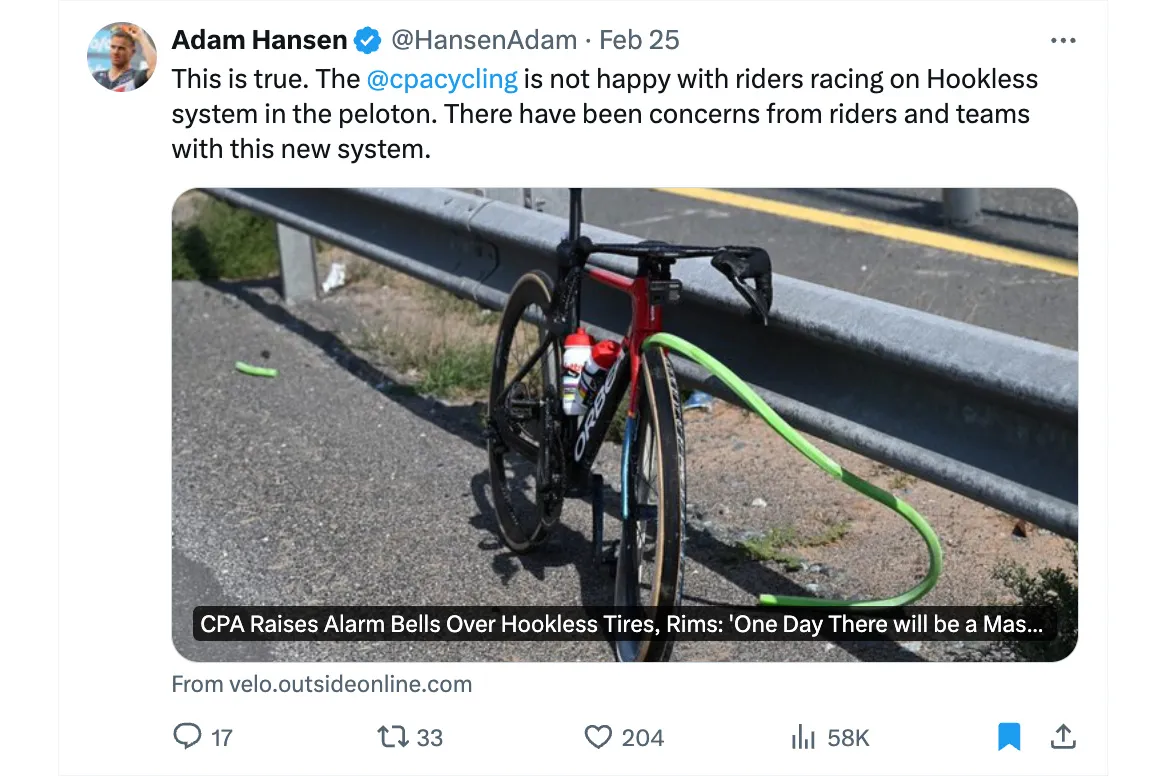

Last week, though, on stage five of the 2024 UAE Tour, Thomas De Gendt suffered a high-speed crash while – seemingly – just riding along.

Following the incident, De Gendt’s bike was photographed standing by the side of the road, the tyre detached from the rim, tubeless sealant everywhere and a broken Vittoria Air-Liner tubeless insert tangled in the fork.

Whether this was a cause or consequence of the crash remains unclear, but many have already pointed the finger of blame at De Gendt’s wheels, a set of Zipp’s 353 NSW carbon wheels with hookless rims.

As a reminder, hookless rims are tubeless-ready rims that lack bead hooks – the protruding edges on the inside of a rim that help retain a clincher or tubeless tyre bead.

Thankfully, De Gendt was able to continue racing largely unscathed, however, the incident raises a few questions as to what happened – and what it may mean for wheel and tyre tech.

28 February 2024 – Vittoria releases statement concerning De Gendt’s crash

Since this article was published, Vittoria has released a statement seeking to clarify details of De Gendt’s crash.

According to the Italian tyre manufacturer, the failure was a result of De Gendt’s front wheel impacting a rock and breaking the rim.

The crash was, Vittoria claims, “unrelated” to the fact De Gendt was using hookless rims.

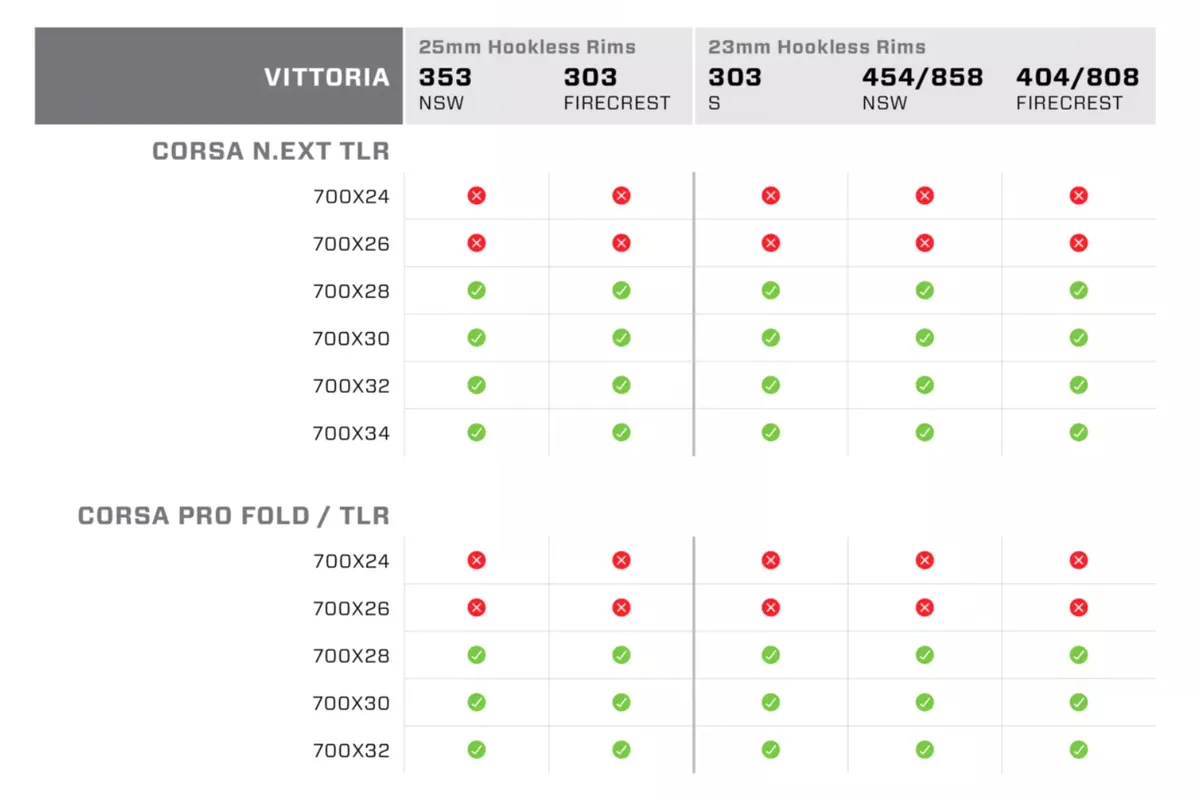

Vittoria’s statement also sought to reaffirm the compatibility of its 700 x 28c Corsa Pro TLR with hookless rims, saying it underwent extensive testing during development, including with Zipp’s 353 NSW wheelset.

Hansen speaks out

Speaking to Velo in the aftermath, Hansen was unequivocal on what had caused the crash, saying “his tyre came off, the safety foam inside got caught in the fork and that locks up the front wheel”.

The next day, Hansen posted a link to the Velo article on X/Twitter, adding: “This is true. The @cpacycling is not happy with riders racing on Hookless system in the peloton. There have been concerns from riders and teams with this new system.“

Dan Bigham, a performance engineer at Team Ineos-Grenadiers (and former UCI World Hour Record holder), then retweeted Hansen’s post, adding “History will not be kind to road hookless”.

For his part, De Gendt seemed less sure, posting, “I would like to know what I hit with my front wheel” on X/Twitter and asking whether anyone had images or footage of the incident.

Could hookless rims be unsafe for use in professional road racing, or perhaps in cycling altogether, or might there be more to this story than meets the eye? Let’s investigate.

What we know – and what we don’t

Though Hansen was definitive about the reason for De Gendt’s crash, it’s not totally clear what caused the incident.

The grainy video footage available appears to show De Gendt’s front tyre detaching from the rim during the crash, but it’s not clear whether he hit an obstacle or suffered a puncture prior to crashing.

We do know De Gendt was using 700 x 28c Vittoria Corsa Pro TLR tyres on a set of Zipp 353 NSW wheels, with Vittoria Air-Liner tubeless inserts.

We also know De Gendt’s teammates were using similar, if not identical setups, with Vittoria Corsa Pro TLR tyres on Zipp hookless rims.

Beyond that, though, there’s much we don’t know.

We don’t know, for example, whether De Gendt suffered a sudden puncture in the moments leading up to the crash that caused a rapid loss of air pressure.

The tubeless insert is supposed to help keep a tyre attached to the rim in these scenarios, but it’s possible there was failure with that piece of kit too.

Likewise, we don’t have details of De Gendt’s tyre pressures. Both Zipp and Vittoria stipulate a maximum tyre pressure of 72.5psi / 5 BAR when using hookless rims. Is it possible De Gendt was running tyre pressures over this limit?

Given his bike would have been assembled by highly experienced professional mechanics, it seems unlikely, but of course, it’s not possible to rule this out (perhaps the gauge on their track pump or air compressor is out of spec, for example).

Could De Gendt’s tyre have been inflated to close to the maximum pressure in the morning (when it may have been cooler) and then been tipped over as the day heated up?

Potentially; though, while it was clearly warm that day (all of the riders were wearing summer cycling kit), reports from the race don’t mention any kind of extreme heat, so this also seems unlikely.

Perhaps more likely is De Gendt hit an obstacle, which caused a sudden spike in tyre pressure and a catastrophic blow-off.

Ultimately, though, we simply don’t yet know exactly what caused this incident. The footage we have isn’t clear enough.

It’s also possible this was just a freak incident caused by a failure somewhere in the rim, tyre or insert system. None of De Gendt’s teammates suffered similar issues that day, after all.

Was De Gendt using an unsafe rim and tyre combination?

One of the key concerns surrounding hookless rims in recent years has been regarding tyre compatibility.

In situations such as this, it’s natural to ask whether De Gendt could have been using an unsafe or unapproved rim and tyre combination, perhaps in pursuit of improved performance.

For its part, though, De Gendt’s team, Lotto Dstny, told Cyclingnews its rim and tyre combinations are “100 per cent in the rules”, and that it follows all guidelines on this topic from the UCI and its wheel and tyre sponsors, Zipp and Vittoria.

Indeed, Zipp specifically lists the 700 x 28c Vittoria Corsa Pro TLR as compatible with its 353 NSW rims, on its Hookless Road Tyre Compatibility Guide.

If they haven’t exceeded the maximum permitted tyre pressure, it looks as though De Gendt and his team have done nothing wrong in this instance.

However, the issue becomes complicated by the latest ETRTO and ISO (International Organization for Standardization) standards for hookless rims. These guidelines state the minimum nominal tyre size for a 25mm internal width rim is now 29mm, not 28mm.

Hunt, for example, notes it capped the internal width of its latest SUB50 Limitless wheelset – which uses hookless rims – at 23mm in order to adhere to these updated standards.

Vittoria says its Corsa Pro TLR tyre is approved for use on hookless rims in a size 28c or larger, but doesn’t offer any guidelines as to internal rim widths on its website.

Zipp maintains its 25mm-wide rims are fine to use with 28c tyres, per its compatibility guidelines.

Speaking to Cyclingnews last year, Zipp said: “We know there have been enough wheelsets ridden in the past several years with the 28c tires on 25mm rims to prove that the combination is safe and delivers many proven performance benefits.”

Clearly, then, there are conflicting opinions on this topic, and an unhelpful amount of grey area.

After all, how many consumers regularly check the latest ETRTO or ISO standards?

Margin for error

Perhaps, no one did anything specifically wrong, but this is a case of exceeding the margin for error.

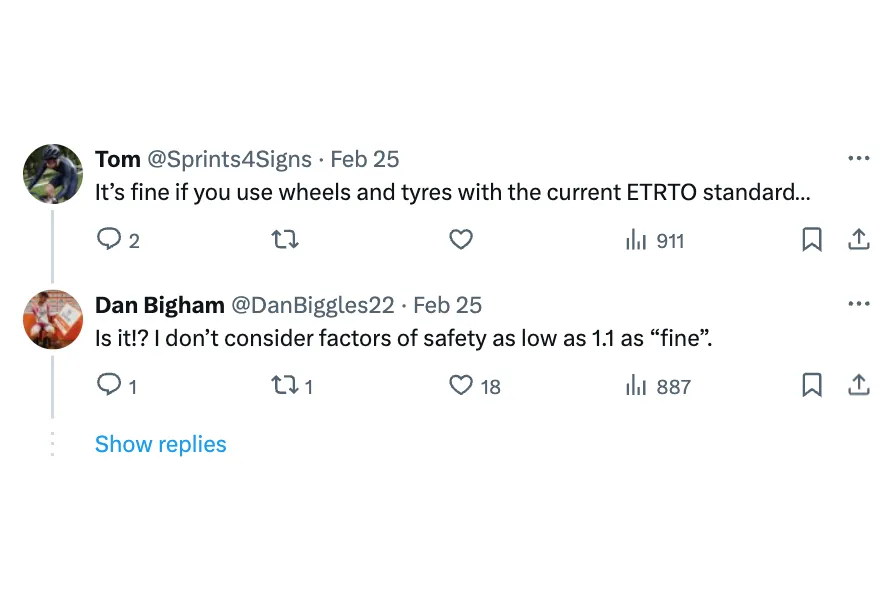

In response to another user on X/Twitter, who said, “It’s fine if you use wheels and tyres with the current ETRTO standard…”, Bigham said: “I don’t consider factors of safety as low as 1.1 as 'fine'.”

A ‘factor of safety’ typically describes the strength of a system in relation to its intended use or load, or in other words, its margin for error.

Though it's not clear exactly what Bigham is referring to, a safety factor of 1.1 relating to the maximum permitted tyre pressure on a hookless rim would, for example, equate to 79.75psi / 5.5 BAR (1.1 x 72.5psi / 5 BAR). This gives the rider a margin of error of 7.25psi / 0.5 BAR.

De Gendt’s setup appears to sit in some sort of grey area – approved by the manufacturer of his wheels and tyres, but potentially not by the ETRTO or ISO.

Does the crux of this issue lie in the lack of – or an insufficient – margin for error, then?

Again, it’s difficult to say, without further clarification of the incident itself and De Gendt’s specific setup. Perhaps it was on the limit of what’s technically safe and a freak incident pushed things far enough over the limit to cause a failure and resulting crash.

Would wider margins of error have prevented this incident? Potentially, but without a clear understanding of what caused this incident it feels impossible to say for sure.

Have we been here before?

This isn’t the first time we’ve seen issues with tubeless tyres in the professional peloton.

Last year’s edition of Paris-Roubaix, for example, also saw a number of riders suffer tubeless failures with tyres dismounting from rims.

The thing is, though, bicycle tyres dismounting from rims in professional road racing isn’t anything new.

Proponents of tubular tyre systems often tout the ability of a tub to stay attached to the rim in the event of a puncture (because the tyre is glued onto the rim), but I’m old enough to remember riders who had tubular tyres roll off their rims after the glue failed during hot races.

I’m even old enough to remember being too afraid to use tubular tape instead of glue, in case it ever happened to me.

Likewise, clincher tyres and rims paired with inner tubes – which some WorldTour teams are still using – also won’t remain securely attached in the event of a puncture.

So what options do we have?

Hooked rims alone are clearly not the solution. If riders aren’t using tubeless inserts – and there’s no UCI rule stipulating they must be used with tubeless tyres – then a hooked rim won’t help keep a flat tubeless tyre on a rim any better than with a clincher one.

One of the riders who suffered a tyre blow-off in the Arenberg trench at last year’s Roubaix was a Team Bahrain Victorious rider running Vision Metron wheels, which feature hooked rims, for example.

Perhaps the best solution is hooked tubeless rims with tubeless tyres and inserts, with two potential failsafes against blow-offs.

DT Swiss, for example, told BikeRadar it doesn’t produce hookless road rims because it believes hooked rims are safer, especially since it doesn’t make tyres and it can’t control the decisions consumers make.

Where do we go from here?

Life was certainly simpler before the advent of hookless rims, as the thorny issue of tyre and rim compatibility reared its head.

However, many here at BikeRadar (myself included) have ridden – and continue to ride – hookless rims and tubeless tyres without such issues.

Indeed, when my colleague Warren Rossiter tested the Zipp 353 NSW wheels in late 2021, he paired them with a set of 28c tyres and suffered no problems.

Does that prove such equipment is safe? Clearly not. Maybe it is, or maybe Warren was just lucky not to suffer any incidents that pushed the limits of that combination. As I keep saying, it’s difficult to be sure.

While significant progress has been made on improving compatibility and standards in this area, clearly there are grey areas and uncertainty remains.

Having a situation where a major wheel manufacturer (Zipp, in this case), and the ETRTO and ISO, provide conflicting information on compatibility to consumers is clearly not ideal either.

The responsibility ultimately lies with the cycling industry to reach a consensus about what is and isn’t safe, and to communicate that clearly to riders, bike shops and mechanics.

I’ve written about this topic at length in the past – in my long-term review of a Giant TCR Advanced Pro 2 Disc, for example – and as I’ve commented before, the benefits of hookless rims may be obvious to manufacturers, but the benefits for riders are far less so.

As with the recent Shimano crankset recall, riders – professional or otherwise – are being left in the dark as to whether the equipment they own (or are considering purchasing) is safe to use, and are faced with confusing information regarding compatibility and best practice.

Unless the cycling industry can get a firmer grip on this issue, the hookless compatibility story looks set to rumble on for the foreseeable future.