Renthal might be famous as a motocross brand, but what goes on behind the scenes of the company’s successful mountain bike wing? Marketing manager Ian Collins spoke to What Mountain Bike about what downhill racers and trail riders have in common, why motocrossers are scared of mountain bikes, and why high-end production will boom in the UK.

On motocrossers rinding MTBs

“Motocrossers can’t do it, it’s amazing. You see them riding round a motocross track and they’re absolutely pinned. The bikes are so stable because of all the weight, you put them on a mountain bike and they’re scared because it’s so light and it reacts to the ground so much they can’t quite handle it. You don’t have to go downhill on a motocross bike, so that’s alien to them as well. Trees too.

“There are two of us at Renthal who are very focused on the mountain bike side of the business, but within the company there are a lot of us that ride and we have a regular Wednesday night ride – it’s a group of between four and seven people. Where we’re based we can ride into the Peak [District, UK] without touching a road.”

Renthal sr4 chainrings – first look

On product testing

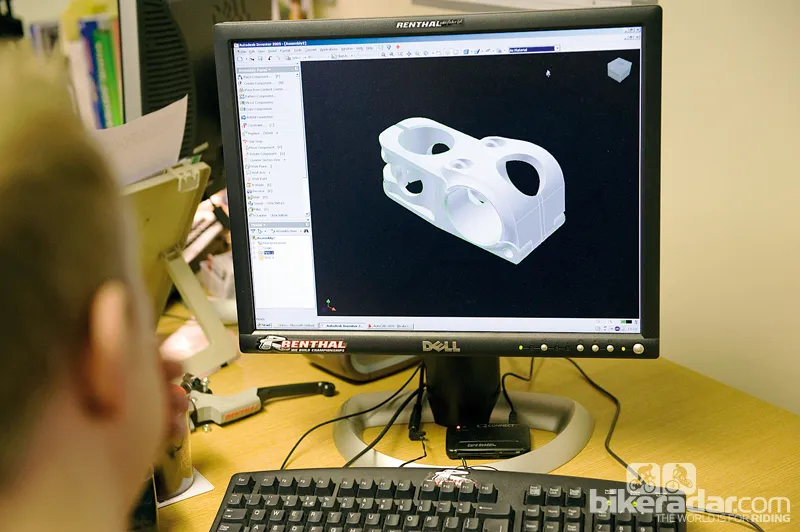

“Testing has to be a big part of what we do to make sure the product is right. We’re not a company that goes and buys an off-the-shelf product and puts a brand name on it; we like to develop something from the ground up. Everything has to be proved by us first.

“In the summer we did a load of data acquisition work. We used a handlebar that we strain gauged with eight gauges: that’s four each side, which we measured loads in the x and y axis. We then did repeated runs on a downhill course using a World Cup-level rider on a downhill bike and an intermediate-level rider on a trail bike.

“We found that the peak loads were the same between the two bikes, so where you’ve got a downhill bike with 8in of travel, the load that’s exerted through the bike on the bar is the same as that exerted through a shorter travel 5in bike going slower.

“We did a load of other data acquisition work based around cross-country, as we want to get an idea of what sort of loads go through an XC bike. We used a shorter travel bike, and a hardtail to see if that made any difference.”

Renthal began transferring their motocross expertise to the MTB scene several years ago

On manufacturing in Britain and whether we’ve lost the skills

“We will see more manufacturing in the UK because it’s getting to a point where it’s similar in cost to produce something here as in the Far East when you take into account duty and shipping, but I think that’s only going to happen at the premium end. At the lower end it will stay in the Far East, or perhaps other countries where labour is cheaper.

“Everything moves so quickly so you can gain that knowledge in new manufacturing techniques. Manufacturing is in a constant state of flux and development; you can just learn the new things that are more relevant to today than old-school mass production style.”

On what makes his job satisfying

“Seeing the brand flourish, to be honest. We always knew it was going to do well but in the last two years we’ve seen it grow exponentially, and obviously I’m at the centre of it, and there’s a huge amount of pride that it’s happening and going in the direction we want it to.”

For more information on Renthal products visit www.renthalcycling.com.

A version of this interview is published in issue 145 of What Mountain Bike magazine, available on Apple Newsstand and Zinio.