There are enigmas, and then there are bike designer Brent Foes and suspension guru Charlie Curnutt Jr. Their unique hand-in-glove relationship led to the development of both platform damping and 2:1 shock ratios.

Marcus Farley talks to Brent Foes about this remarkable working relationship. But first, he talks to Foes about his first foray into the world of commuter biking.

2010 Pasadena Crown City commuter

The new commuter bike seems, on the face of it, like a huge departure from Foes’ full-suspension norm. "But it comes from the same basic engineering principles that have allowed me to build in variant qualities of ride with the same chosen materials," he says.

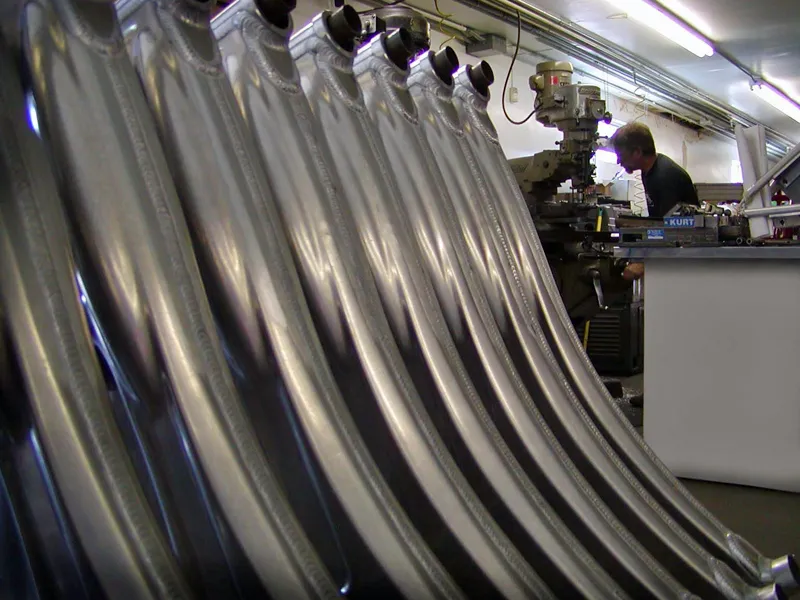

"Optimising the shape of hydroformed aircraft-quality aluminium monocoque, then mating it, with hand-crafted welds, to strong but light Easton 6061 aluminium double-butted tubing with our Foes-designed and milled CNC’d connectors.”

Foes is keen to pitch the bike to the customer who wants “a really special, handmade-in-the-USA commuter bike”. His own design brief was simple: “The way I designed the bike made no concessions on acceleration. In city conditions, a bike must be not just light but agile, and have a subtle small amount of give that makes it comfortable.

“The interesting thing that we found as we developed this frame is that even the very expensive aluminium commuter frames felt pretty much like riding around on a coffee can – hollow, 'thunk-ish', crude.

"But our monocoque frame created the perfect combination of lateral stiffness for acceleration and small bump compliance for comfort that I was looking for. The bike is no beach cruiser. It is a responsive city bike for the enthusiast who wants a more upright, retro position.”

Foes decided to shy away from drop bars as, in his experience, “serious commuters find that the road bike position makes it difficult to see traffic and other city hazards, while a more upright position is comfortable and reveals better sightlines".

UK pricing is expected to be around £1,300-£1,400 for a complete bike with aluminium fork, bar and seatpost, or £1,500-£1,600 with a carbon fork, bar and post. Complete bikes will cost $2,099 and $2,599 respectively in the US, with the frameset at $11,99.

2010 full-suspension

Foes only makes changes when he thinks they are absolutely necessary. For example, for 2010, the only change to the popular 2:1 FXR 'aggressive mountain' bike is that it will be available with an optional 150mm x 12mm through-axle rear and a floating brake mount.

The big news is that he is ready to unleash his take on the big-wheeled 29er market, the B-29. “It will feature our 2:1 rear leverage ratio, have four inches of travel and be one stiff son-of-a-gun!” Expect more news soon on this new addition to the Foes line-up, which is set to be unveiled at the Interbike show in Las Vegas in September.

For the not-too-distant future, he’s also working on a new 2:1 DHS Mono downhill bike. “I don’t have anything fleshed out yet, and I don’t want to tell you a whole lot before some test mules have seen a lot of dirt, but I will say that it’ll be lighter and easier to work on," he says. "Oh… and it’ll be a sick-looking design!”

The Curnutt connection

Foes' association with the Curnutt family goes back three decades. “I knew Charlie Curnutt Sr when we were racing trucks in Baja and the South-West, and Curnutt shocks were the way to go if you wanted to win in the desert," he says.

After Foes switched his attention to mountain bikes in 1991, the first person he thought of to make a rear shock for his frame was Charlie Sr. “But he thought it would be better to speak to his son, Charlie Jr about this project," says Foes. "Junior was building shocks for peewee off-road motorcycles using his patented cavity system. Charlie Jr said this technology would be ideal for a bicycle. We spent close to four years developing this shock to work on my frames.”

The fruits of those labours were so successful that the results are still mimicked by competitors today and, while Foes and Curnutt still work closely together on improving the shocks’ overall performance, they believe that they “have not been able improve on the original platform of the piston-cavity technology” that they worked on over a decade ago.

Foes' relationship with Curnutt became even more important when Charlie Jr wanted to bring his ideas about lower leverage ratios to Foes' designs. “We found that by lowering the rear suspension ratio to 2:1 we would reduce stress on the frame overall, and with the lighter spring rates needed we could reduce shock stiction," says Foes. "Working closely with Charlie on a purpose-built shock for this new design was the key factor in its success.

“Usually when a manufacturer comes up with an idea for a new design it must accommodate the existing shocks on the market. We work the other way around – we build the shock the way we want it and then build the frame around it. This has allowed us to build suspension qualities – like stable platform – into the shock and retain the use of the single-pivot design.”

Sticking with the single pivot

Foes’ continued use of single pivot designs is purely functional. He believes that it is "the stiffest design, bar none". "Mating it with the 2.1 shock ratio, we have eliminated the need for multiple pivots, links, dog legs or anything else that wants to flex,” he says.

So, does that mean stiffness is more important than how the bike tracks the ground? Foes says it is important to distinguish between stiffness and small bump compliance/plushness.

"Perhaps it’s just my vernacular, but I speak about frames and their elements in terms of ‘stiffness’ and suspension in terms of ‘compliance’, as well as platform, damping and bottoming resistance," he says. "To me they are not the same thing, and confusing the two can lead to confused handling, acceleration and braking.

"This is one reason why we try to design our frames around a high-performance shock and fork, and not the other way around. We try to build in lateral rigidity – stiffness, if you will – into the front triangle, rear triangle and the connection between them. Then, the entire suspension – placement of the single pivot, shock, fork and leverage ratios – can be optimised for the type of riding the bike will see.

"These two different things, frame rigidity and suspension compliance, done well and working in tandem create a high-performance bicycle."

Factory team

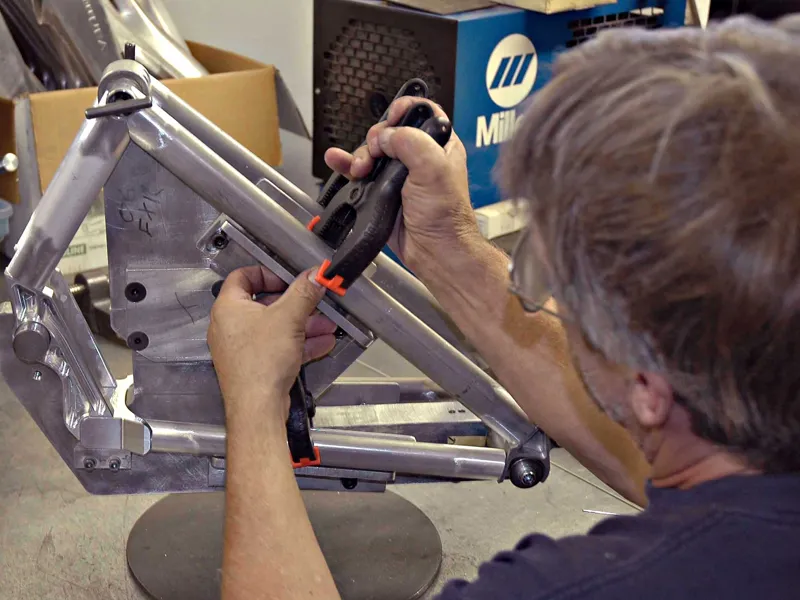

Foes Racing is a small, tightly knit team based in Pasadena, California. Foes hand-fabricates his frames and shocks with the support of a three-man team: an engineer, a master machinist who makes connectors for frames and a Curnutt-trained shock builder.

He has two master welders whom he intermittently employs, but for the most part if you buy a Foes frame, Foes himself welded it. He makes sure to weld every single monocoque top tube.

In terms of support staff, there is a head technician – who assembles and straightens frames, and prepares everything that leaves the facility – and a brand manager – who acts as general manager – plus some clean-up and shipping guys. Keeping everything ticking over is marketing director Margot Core.

Form over function

As an ex-racer, Foes says he builds bikes from a racer's perspective. “I got into bike building because I like to be hands-on in fabrication work, trying new ideas, challenging others and working on suspension," he says. "This comes from years of building off-road trucks and racing them. It’s the same show – just a different venue.”

So, what does Foes feel that bike racers want? “To me, serious competitors want the highest function, longevity and least amount of maintenance from their equipment – even at the cost of its form."

However, that is not to say that form isn’t important to him. “Over the years, I have found it to be very easy to develop striking designs around the technology that works the best,” he says. The secret, he believes, is not to fight the function.

"I just let the design inspire me to create something beautiful around it," he says. "My philosophy hasn't changed much from when I first started 17 years ago. I like a frame that is rigid, simple (in the number of pivot points) and built around a high-performance suspension. I prefer to use monocoque designs because it serves these points well – its strength, weight and ability to take on any shape being excellent.”

Credit crunch

Foes comes across as an incredibly positive guy. His enthusiasm and passion is evident in everything he does. He’s definitely your archetypal glass-half-full type, keeping up his positive outlook even when we discuss the credit crunch.

“I know everybody is feeling the hard times right now but you know that we’ll work our way out of it and get back to normal," he says. "I still work just as hard as I always have, and I try to think positive – things could be worse.”