Trek’s race department is heavily tasked. This six-man team must support the company's professional race teams and individual athletes, and use those programs to test new products and make existing products better – because at Trek, they race what they sell, and sell what they’ve raced.

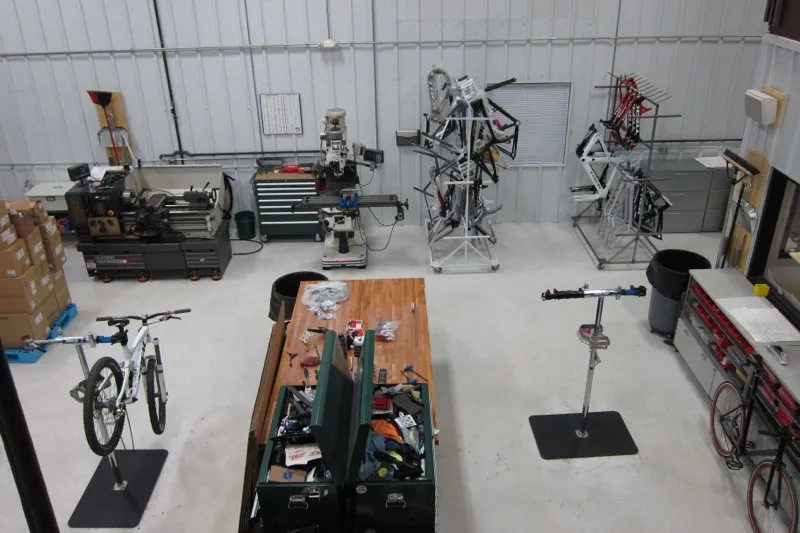

The team, who are a mix of engineers, ex-racers and mechanics, work out of a 3,000sq ft corner of Trek’s massive 205,000sq ft headquarters in Waterloo, Wisconsin. Every single one of the company's sponsored bikes runs through this 'Race Shop', from those used by K-Swiss triathletes, the C3 gravity program, Trek World Racing and the new RadioShack-Nissan-Trek road squad, to privateer athletes and outfits, like the new ODI-Trek squad.

Between them, these teams require roughly 1,000 frames per season, which range from the new carbon fiber Session 9.9 downhill bike to the super-fast Speed Concept triathlon and time trial machine, and everything in between.

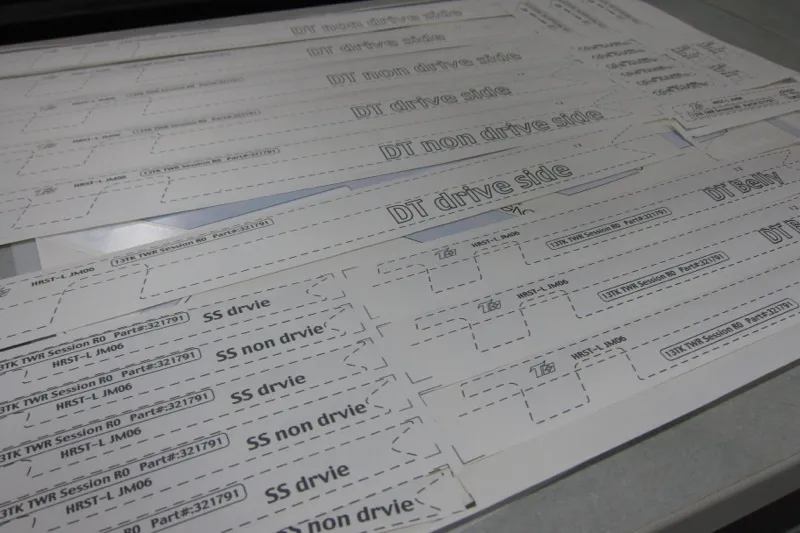

Slick colour scheme for the new RadioShack-Nissan-Trek Speed Concepts

The Race Shop was founded due to pressure from Lance Armstrong for better products during his Tour de France reign. “The starting point was the Lance rise, and what we needed to do to support that,” said Mark Andrews, the department's road and triathlon engineer. “Having dedicated resources to support teams became a huge asset.”

For years the race department was part of the Advanced Concept Group (ACG) and run entirely by Andrews and Scott Daubert, who then served as Trek’s 'Lance liaison'. The 'shop' was just a small corner in Trek’s prototype lab. Then, when Trek took on full equipment support of Astana in 2008, the department grew and the true Race Shop space was created.

The Race Shop has four work areas for building bikes

“We’ve always been best-in-class, with dedicated outdoor support and dedicated indoor support [for our race teams] that's superior to our competitors,” said Ben Coates, Trek’s former road team liaison and current road product manager. “It shows, at least to us, in the support and happiness of our athletes.

"In 2008, we signed up for Astana, and we were full clothing, full bike, everything, and it was a huge undertaking. At the end of that year John [Burke] and Joe V [Vadeboncoeur, Trek's vice president] talked about expanding our racing presence. We spent a bunch of time identifying what would limit us from doing it properly, and the dedicated space and people were the two hurdles that we had to overcome.”

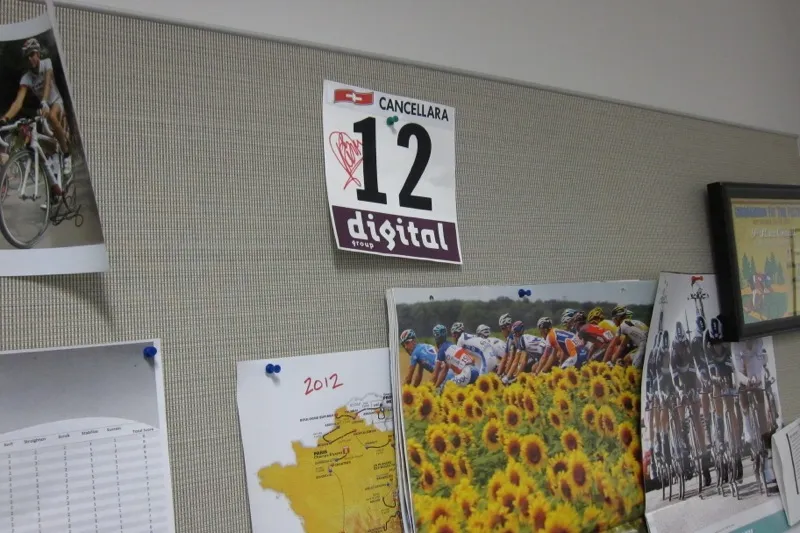

The Race Shop has quite the pedigree

While the department was founded to support Trek's headline road team, its directive – to be on-time and on-target with race team support that's second to none – transfers to all of the company's sponsored teams and athletes. The expansion of the Race Shop allowed Trek to take on Martin Whiteley’s Trek World Racing outfit and the C3 gravity program in 2010, and in 2011 a second top-tier European professional road team, in the form of Leopard-Trek.

“The additional teams were only possible, and successful, because we set this place up to support them,” Coates told BikeRadar. “You hear about a lot of teams having the disaster of not getting enough bikes fast enough, or new paint schemes, or new product, or stuff like that, and we really don’t have those problems.

The department has its own press and lathe

“Mark has a great connection with the manufacturing group and this room really operates as a leverage point. Ray [Waxham, mountain bike teams technician], Vance [McCaw, C3 technician], Matt [Shriver, team liaison] and Scott [Daubert] can walk up to anyone in the building and say, ‘I need something’, and then use their resources in this room to leverage our external [to the Race Shop but still within Trek] resources to supply and fulfill all those needs."

Making all of this possible are Trek’s on-site engineering, product management and 'halo' product production teams. Without that last resource – the on-site carbon factory and custom metal production – Trek’s race team support could never be as successful. Managing a similar Asia-based program would be harder, and infinitely slower. “In the event that we have an issue, it’s not just four guys back here in a room trying to solve it,” said Coates. “It’s a 'four guys who have the run of the company' kind of deal.”

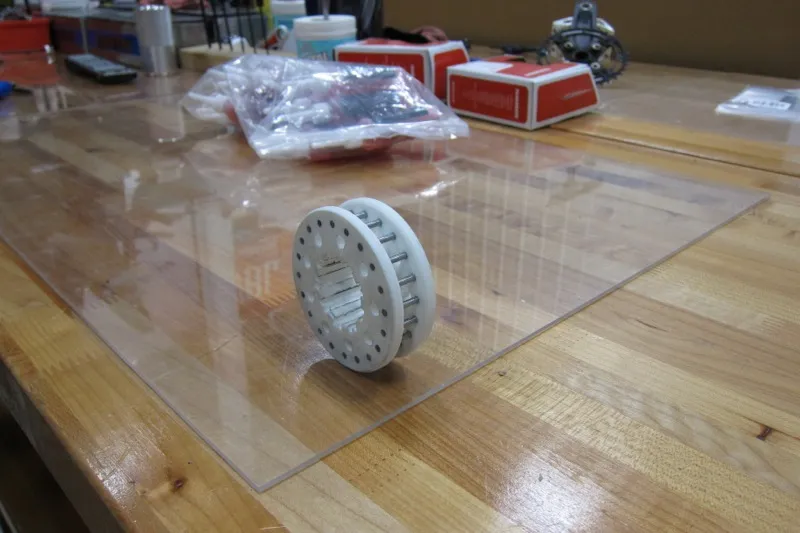

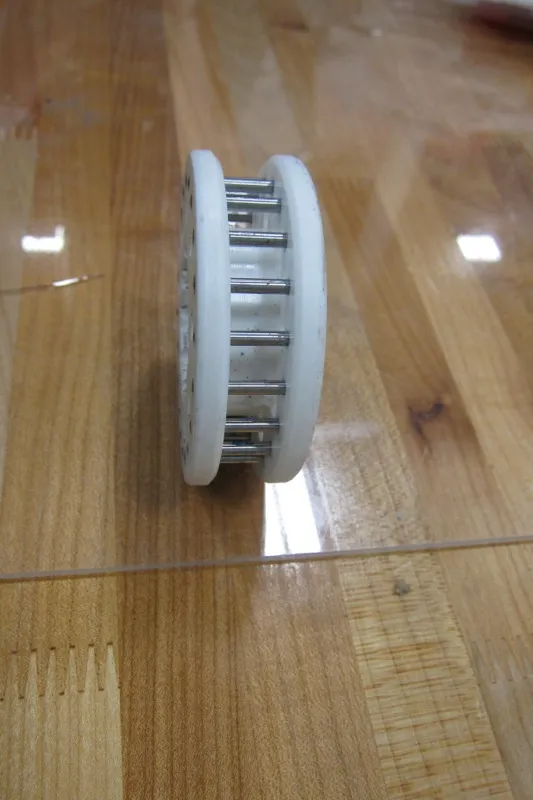

One of the Race Shop’s prototype aero downhill wheels

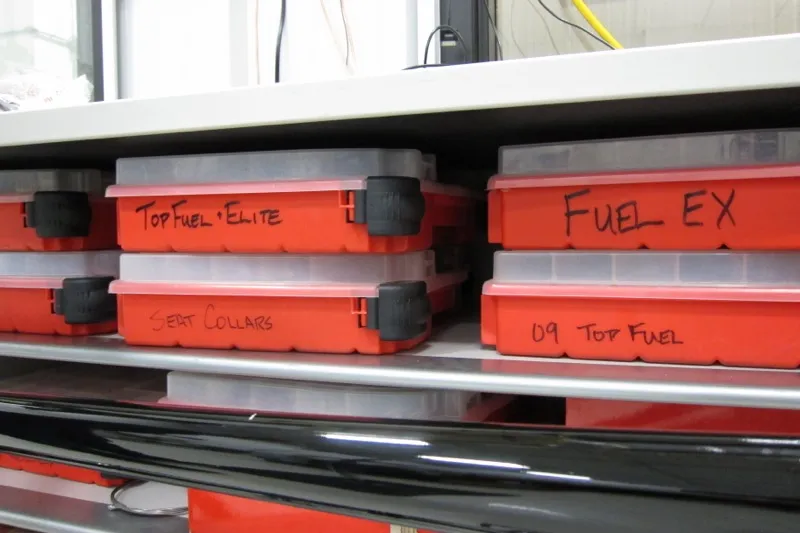

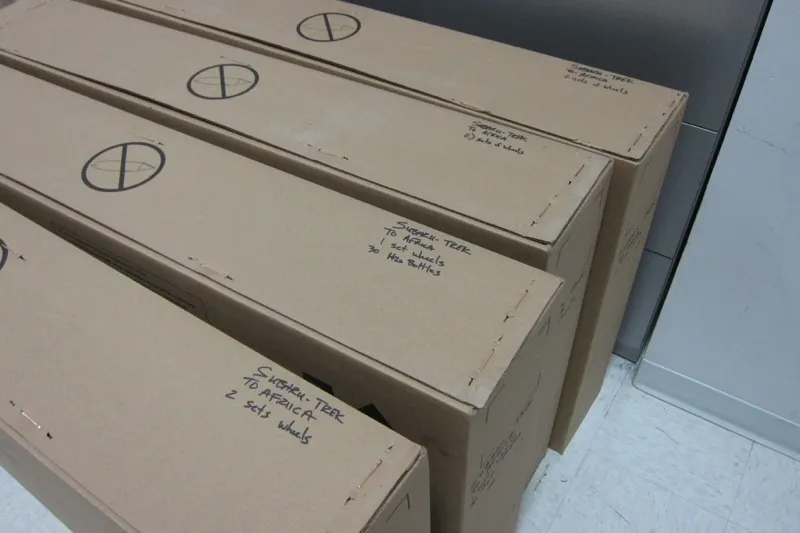

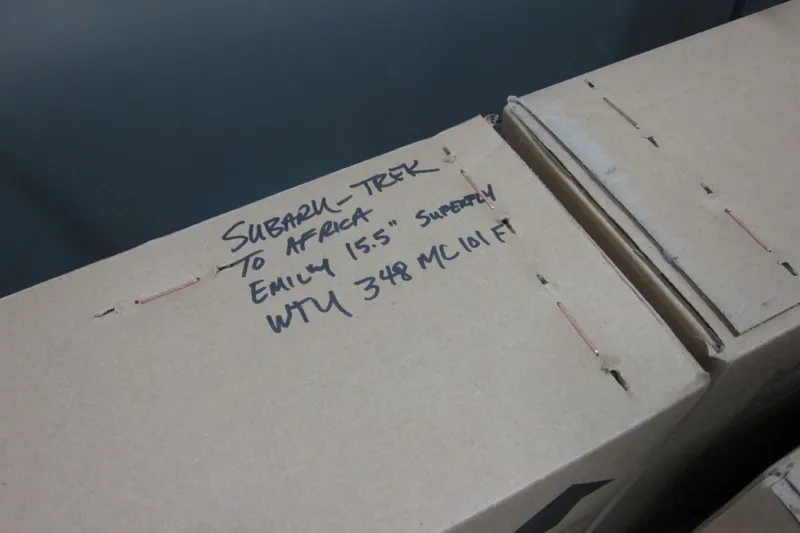

Of course, it's not all about custom products. There's plenty of more menial work to be done, too. “Simply putting the bikes in boxes can be a huge challenge,” said Coates. “Making sure they’re all painted properly, sized, have headsets in them [or any other parts], screws, nuts and bolts, and all that, is really what this place does; it makes sure that we deliver on time, on target, and that the support is second to none.”

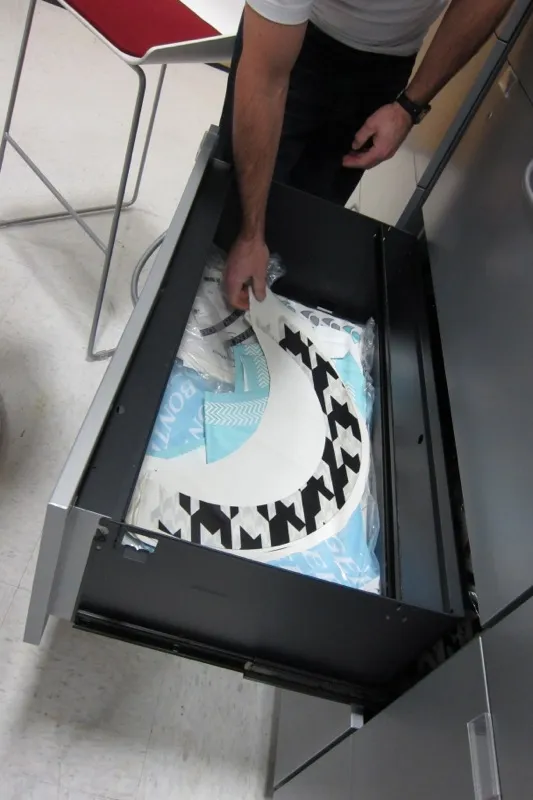

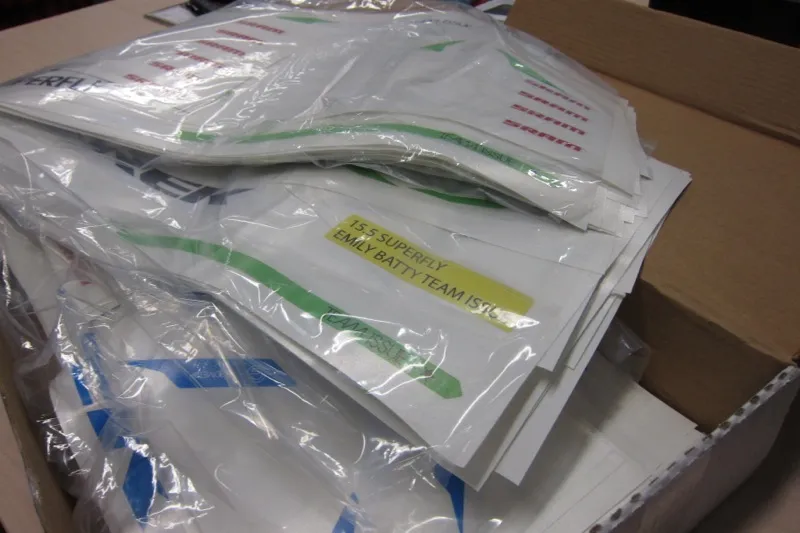

Case in point: the day BikeRadar visited the Race Shop, Matt Opperman and Jon Rourke, the head mechanic and team manager from Subaru-Trek, were there to pack and ship all of their team’s equipment for the first UCI World Cup mountain bike race of 2012 in South Africa.

A Subaru-Trek Superfly ready to be transported to South Africa

The fun stuff

It’s not all spinning wrenches and packing cardboard, though. The Race Shop facilitates all kinds of special team projects. It’s a playful environment and you can tell Andrews, Waxham and McCaw have a fair amount of fun doing their jobs. Recently, Waxham made some custom horizontal dropouts so he could build Frank and Andy Schleck a pair of fixed-gear Madone training bikes.

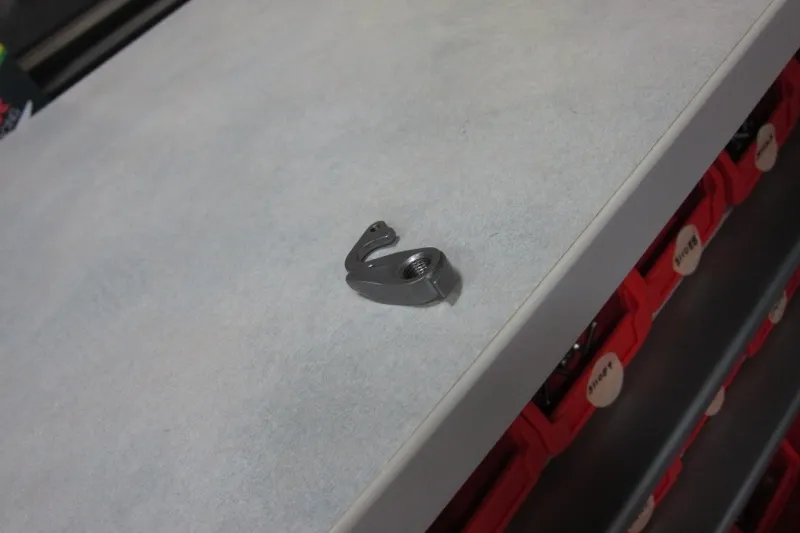

“They [dropouts] are actually from our T1000 track bike,” he said. “And it allows them [the Schlecks] to have a bike that fits just like their race bike, but have a fixed-gear training tool. We did two 58cm bikes for them in the same team colors; they were kind of cool looking once they were built up. Those are the little side things and little tweaks that we’ll do to production stuff, if there’s a request.”

The Schlecks' custom Madone dropouts

The engineers also build their own custom projects just to stay sharp and creative. Andrews is known for his custom bikes for his two girls, and Waxham has become interested in the fixie scene. “It’s great to be able to have stuff at your fingertips,” said Andrews. “Ray has been doing a lot with fixies and belt drives. I like the kids' bikes. It’s just, ‘I want to try this’ [type projects]. Anyone can make a regular bike but [we like] taking it to the next level. Like, we did a bike for Shaun Bradley, who’s 7ft 6in, a few years ago.”

Other projects can range from prototyping shock linkages for the gravity teams – Ross Schnell needs these because he runs RockShox rear shocks instead of the stock Fox dampers – to playing with different derailleur hanger materials. Recently, the Race Shop played a part in the Madone 6.9 SSL’s swap from an alloy to carbon front derailleur boss, as well as other odds and ends like this.

One of Andrews' pet projects

Andrews built this mini carbon hardtail for his daughters, who've since outgrown it; those cranks are carbon and just 145mm long