Earlier this week we expounded on the reasons why the new T47 bottom bracket standard shouldn’t be summarily dismissed as “just another damn standard to deal with.” In fact, it could become a solution for many — but probably not all — of the issues associated with creaky Press Fit 30 bottom brackets. While the design has merit, there are also significant issues that are likely to keep T47 from becoming the one bottom bracket standard adopted by the entire cycling industry.

Related: Six reasons to like the T47 bottom bracket standard

Here are five reasons why T47 won’t solve all of the cycling industry's bottom bracket woes.

1. Not right for every type of bike

T47 isn’t a panacea for every press-fit standard, and isn’t necessarily the right solution for every type of bicycle.

According to Mark Norstad of Paragon Machine Works, the go-to parts supplier for many custom frame builders, the T47 bottom bracket shell will come in at least seven different widths. While it appears that sourcing a T47 in one's preferred width won't be an issue for manufacturers, the overall dimensions of the design do pose challenges that make it a non-starter for some companies' full-suspension mountain bikes. That's because the overall dimensions of the T47 standard encroach on space used for suspension pivots.

Case in point: Santa Cruz Bicycles — a stalwart proponent of the tried-and-true 73mm threaded bottom bracket — doesn't see a point in the new platform and would have to redesign its lower suspension linkage in order to accommodate it.

"There's no doubt it would cause some packaging issues. Nothing insurmountable probably, but it's years and a total product line overhaul around it. And for what? Last I checked there were 30mm spindles for MTB use," said Joe Graney of Santa Cruz Bicycles.

Related: BikeRadar’s Complete Guide to Bottom Brackets

Santa Cruz is one example of a company that would have to redesign its suspension system to accommodate a T47 bottom bracket. That's not likely to happen

2. Not the ideal retrofit for creaky Press Fit 30 frames

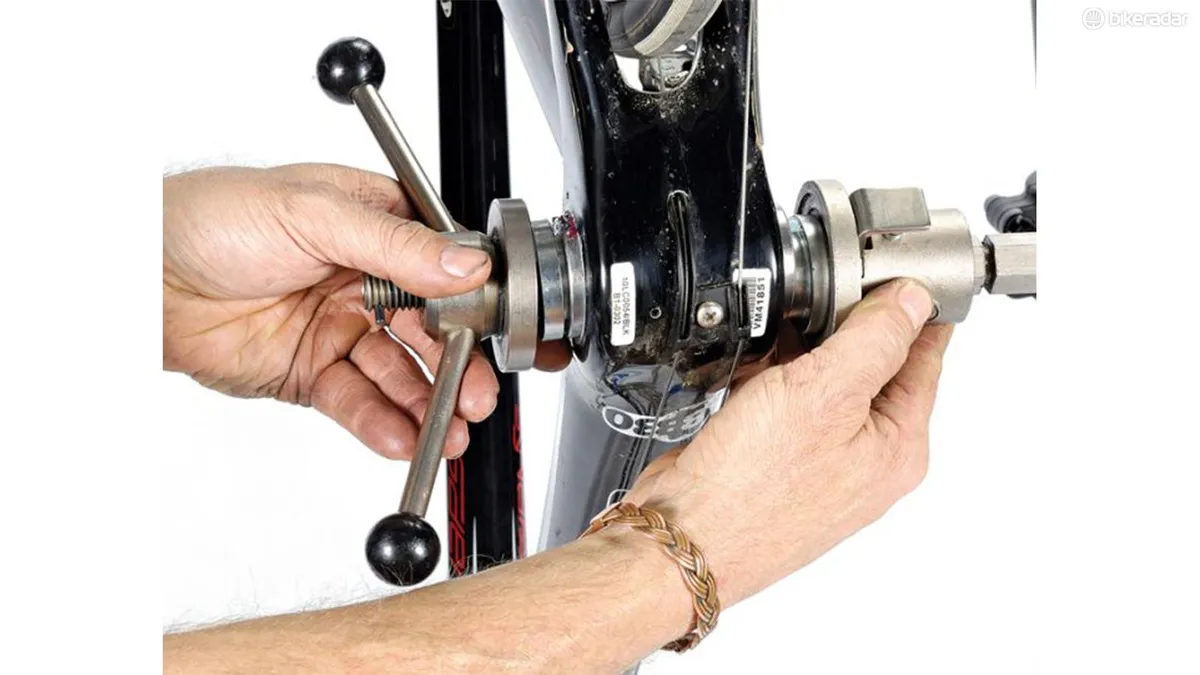

One of the benefits of the T47 standard is that it was designed with dimensions that are nearly identical to Press Fit 30 bottom bracket shells. In fact, it’s possible to cut threads into a PF30 shell in order to run a T47 bottom bracket, such as Chris King’s Thread Fit 30i.

There are several problems with this approach. First off, this will certainly void your warranty.

Cutting threads into a metal frame with a PF30 shell won’t be a cheap fix, either. Estimates vary, but it is possible that it could cost upwards of $500 to cut threads into steel or aluminum a PF30 shell, perhaps even more for titanium. Finding a shop with the expertise to do it properly will also be a challenge.

Moreover, creaky shells can already be silenced by aftermarket bottom brackets with cups that thread together, such as those from Praxis Cycles, Enduro, Wheels Manufacturing, and others. Even with ceramic bearings fitted, any of those options will be cheaper than cutting threads into a frame. They also won't void your warranty.

Last but certainly not least, if your frame came from the factory with an out-of-spec bottom bracket shell, demand a replacement!

The best remedy for a creaky PF30 bottom bracket isn't threading it for T47, it's using a expanding press-fit bottom bracket, such as this one made by Praxis

3. Weight gain is a real concern

One of the benefits touted by companies using press-fit bearings is that this approach allows the bearings to be pressed directly into carbon frames. Threaded systems require metal sleeves, which add weight.

While many riders would to be glad to have a silent bottom bracket in exchange for a small weight penalty, there are companies, consumers and professional athletes who want the absolute lightest, most competitive frames that can be produced. Depending on the type of press-fit system you're comparing it to, the T47 design could easily add 100g — nearly a quarter of a pound — to a frame.

This weight gain will turn some folks off from T47, particularly when the technology already exists to produce creak-free press-fit frames.

Which brings us to the fact that...

4. T47 is a solution to a problem that shouldn’t exist

Chris Cocalis is the owner of Pivot Cycles and a proponent of well-designed press-fit bearing systems. He points out that press-fit systems can work, so long as component and frame manufacturers actually adhere to a set of tolerances, like they do for headsets.

“We need to take a better look at press-fit and the overall tolerances. It’s not perfect, but there is a way easier fix than going to a new threaded standard. Cane Creek, FSA, and every headset and frame manufacturer adhere to the same tolerances for headset cup sizing and frame sizing. We do not currently have this level of standard for press-fit [bottom brackets].

"It’s not the system that is bad, but the implementation of the system to manufacturing on a larger scale that has not been handled well by several manufacturers and factories, which has given press-fit a less-than-perfect reputation. Manufacturers need to hold tighter tolerances just as we do for head tubes. Headsets get pressed in and there have not really been any major issues since the late '80s for press-fit headset cups. I think frame manufactures are improving their press fit BB tolerances as everyone has realized the critical nature of this interface,” Cocalis said.

If all manufacturers kept their press-fit tolerances in check, T47 wouldn’t need to exist

5. Years away from widespread introduction

To date, the handful of companies that are on board with T47 are all small, custom frame builders. This is because they have the ability to switch component standards with each frame they build. Contrast this high level of flexibility with the multi-year timelines of large manufacturers and you start to see that press-fit systems aren't going away any time soon.

Even if a large company such as Giant, Trek or Specialized saw merit in T47, it would be several model years from now before T47 bottom brackets could be incorporated into production bikes. In this same amount of time, it would take less effort, and less money, to reign in existing press-fit tolerances than it would to switch to an entirely new bottom bracket standard.

Final thoughts

While T47 is likely to become one among many competing bottom bracket standards, the introduction of a new standard designed to remedy issues that press-fit systems shouldn’t experience in the first place may push companies to be more precise in the construction of frames and components.

This trickle-down effect could mean that regardless of what bottom bracket standard your next bike uses, it’s more likely to be properly sized and silent.