One hundred years ago, Orbea were manufacturing gun barrels at their factory in Mallabia, Spain. Having switched from barrels to bicycles in the 1930s, they now have two facilities making their product – one in Taiwan for high-end carbon bikes, and one in Portugal for their less expensive models.

In order to offer bikes at competitive prices, Orbea no longer manufacture anything in Spain, but their Mallabia base still plays a key role in getting product to the showroom floor. Essentially a large-scale paint and assembly shop, every Orbea bike makes its way there to be painted, prepped and assembled before being shipped to dealers worldwide. A 120-strong workforce responsible for these finishing touches can ship up to 750 bikes out the door each day.

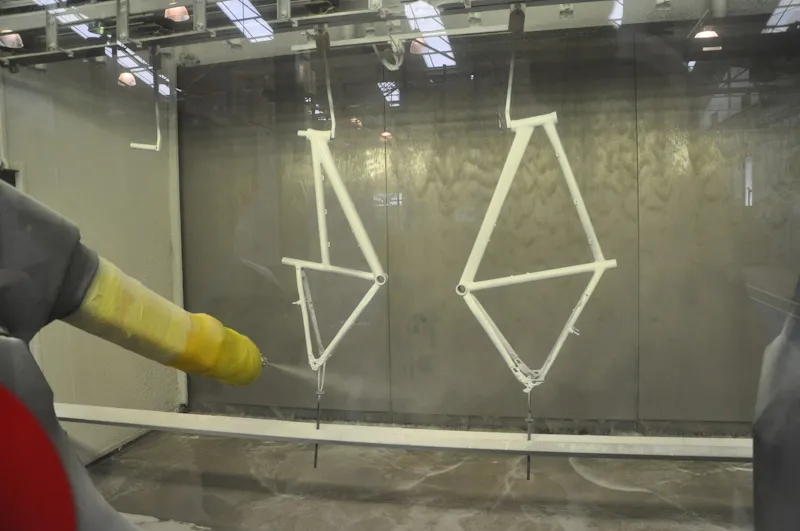

A pricepoint hardtail is sprayed with its clear coat by Orbea’s automated paint system

Orbea shoot for a turnaround time of three weeks from the time a bike is ordered to the time it's shipped, and until a frame is ordered, it hangs in the Spanish facility unpainted. High-end frames are hand-painted whiler lower-end ones are run through an automated painting system that Orbea claim is “eco-friendly”. Once painted, decals are applied and the frames make their way to the assembly lines.

This entire section of the Orbea facility is dedicated to decal installation

Higher-end frames usually require a bit more attention to detail, with customizable My Orbea build kits being installed in an area similar to a bike shop. The rest are still hand-assembled, but make their way down a meters-long conveyor belt, stopping at individual workstations for parts and packaging, before being taken off the line and put into a shipping box.

The majority of Orbea frames are assembled on this conveyor-assisted line

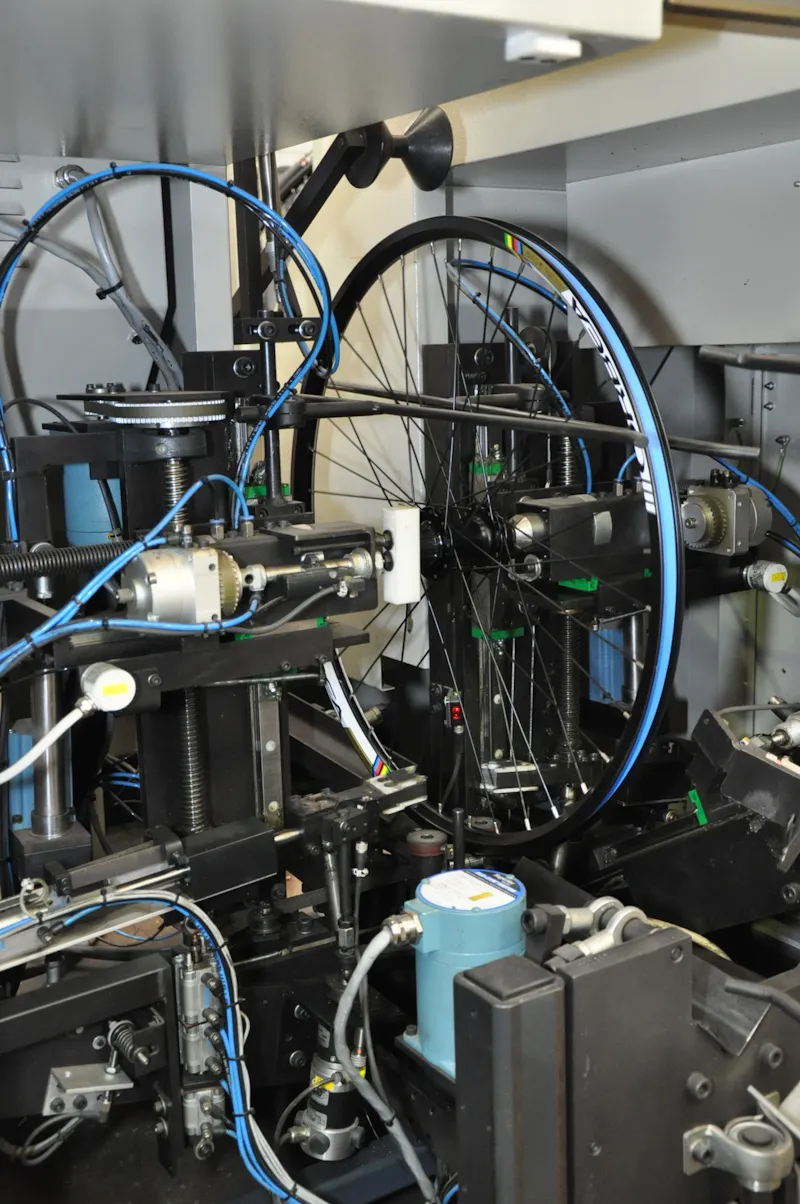

Another 80 Orbea employees work in the building’s offices, bringing the 100 percent employee-owned facility’s head count to just shy of 200. One area of particular interest is their in-house testing facility, which Orbea claim is the only one of its kind in Spain. Carbon frames are put through 18 different strength tests and must pass stress tests that exceed CEN standards; this stringent testing enables Orbea to issue a lifetime warranty with most of their frames.

Orbea do their own in-house frame testing