In recent years, carbon fiber clinchers have gained in popularity as they deliver on a big promise: the light weight and performance of an all-carbon-fiber wheel previously only available as a tubular, combined with the convenience of a clincher.

There is only one problem: extreme braking can — in certain instances — cause certain rims to fail. The high heat from extended, high-intensity braking can soften the carbon brake track, and the internal pressure from the tube causes the brake track to bubble out.

When presented with this fact, wheel companies are quick to retort one of three ways:

- this problem has been solved

- this problem only existed with other brands’ carbon clinchers

- this problem only arises if you’re negligent and/or aren’t an experienced rider

Nonetheless, at least one event has taken notice. Levi’s GranFondo has 'strongly discouraged' the use of carbon clinchers at the upcoming 5,000-plus-person event in Santa Rosa, California, after a handful of riders experienced wheel failures in past editions.

Event director Greg Fisher is careful to be diplomatic.

“We’re not against carbon clinchers. I don’t want to be the event that’s pointing fingers at manufacturers. That is certainly not my intention. The bike industry makes so much great stuff; sometimes as riders we forget our responsibility to check or properly use our gear,” Fisher said. “But, we want people to be informed.”

Fisher said the handful of wheel failures at Levi’s GranFondo could have been caused by a number of things. “Maybe it was a problem with carbon clinchers made five years ago. Maybe it was user error. Maybe it was faulty user maintenance. But the situation was that the heat build-up from braking combined with outward pressure caused catastrophic failure a few times, and really spooked some riders.”

Fisher also pointed out that Levi’s GranFondo is a technical course, with a number of steep, winding descents.

Wheel companies test and refine

Most wheel companies will acknowledge that in the past some carbon clinchers did pry open at the brake track with hard, extended braking. But all wheel companies say they have since done extensive testing on the subject, and have improved the brake track through better resins, treatments or other solutions. Some companies specify the exact type of brake pad to be used. Using a non-Reynolds brake pad on a Reynolds wheel, for example, voids the warranty.

We talked to Zipp, ENVE, Williams, Easton and Reynolds about their carbon clinchers.

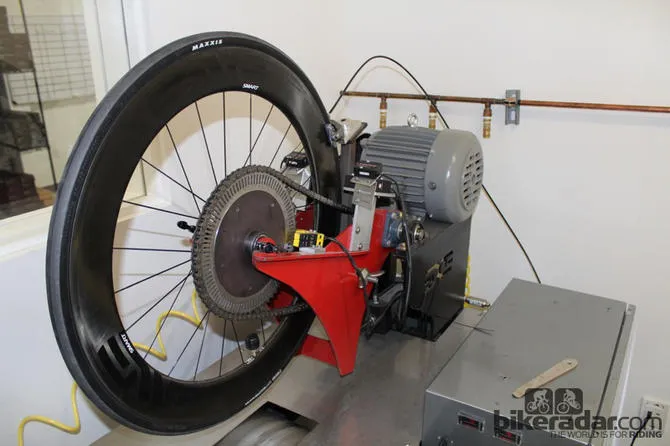

Based in Ogden, Utah, ENVE built a brake-test machine in 2010. To calibrate the machine, ENVE employees used Thermax heat measuring strips on the inside of test wheels when out riding long descents. They found the average heat created on a carbon brake track is about 200 degrees, said test engineer Brent Pontius, and “at most 300-350.”

As a motor-driven belt drive spins the wheel on the test machine, ENVE brakes the wheels with between 400 and 600 watts of power, for up to five minutes. This test generates about 250 degrees of heat on the rim.

ENVE's brake track testing machine

Pontius said that such braking will add about 11-13psi to a tire as the air inside heats up and expands.

To fail the test, ENVE looks for a ten-thousandth of an inch variance in rim width. When carbon clinchers fail on the road, the rim will usually bulge out much wider than that, enough to create a big pulsing effect as the wide section moves through the brake calipers. In worst-case scenarios, the tire will come off. Pontius says that in years of testing a variety of brands’ wheels, he has never actually seen a wheel actually completely break apart.

[BikeRadar’s anecdotal evidence aligns with Pontius’ findings. Two BikeRadar staffers — both 185 pounds — have experienced heat failure on carbon clinchers. And as a staff we have certainly seen and heard accounts of others. In all cases — even the rarer ones where a flat tire immediately resulted — the wheel stayed generally intact, though warped and/or cracked.]

“With the implementation of this test, our product has improved a lot,” Pontius said. “We now have a zero-return rate on the carbon clinchers.”

This year ENVE implemented a five-year warranty.

At Zipp, carbon clinchers come with a rider-weight limit, starting at 225lbs on the 303 wheels and up to 250lbs on the 404 carbon clinchers and the 808 models.

“We know of far heavier athletes riding the wheels every day without issue, but they tend to be good bike riders and even though they exceed the recommended weight limit are not hard on the wheels,” said Zipp’s technical PR manager David Ripley. “From an overall safety awareness standpoint we have to draw a line in the sand, and our stated weight limits are that line. The only other warnings are that the wheels require a carbon specific brake pad; preferably ours as we can control the testing and know data as it pertains to their properties and limitations. And lastly, that tire pressure does not exceed 125psi, which is pretty standard within the industry.”

Ripley said Zipp has not had a wheel returned for heat failure.

Similar to Zipp, Williams Cycling sells its carbon clinchers with a weight limit, ranging from 190bs for the System 38 up to 225lbs for the Sytem 58 and System 85.

“Early on many companies had trouble creating products that were durable enough to handle the intense demands of braking on a carbon clincher rim,” said company president Keith Williams. “We believe technology has developed to a point where quality solutions exist. Through development of special resins and new brake pad formulas, Williams has made huge strides in addressing those demands. Our latest generation carbon clinchers have only been in the market for a few months, but so far we have not had a single issue.”

At Easton, engineers built a machine similar to ENVE’s in concept. Early on in the carbon clincher evolution, Easton tested heat forces with a data acquisition system on a bike. They sent riders out with a 100-pound weight in a backpack, to descend a two-mile hill. Then they replicated those forces on a test machine.

“Every brand broke apart on this machine,” said Easton spokesman Mark Riedy. “Then Easton created ThermaTech with an outside vendor that provides a layer of heat protection.”

Easton carbon clinchers now do not have a weight limit. “For Easton, there is no asterisk,” Riedy said.

At Reynolds, carbon clinchers do not come with a weight limit. Reynolds marketing manager Rob Aguero admits that the wheels — if intentionally pushed hard enough — can be made to heat fail, but insists that this just doesn’t happen in regular riding or even professional racing.

“Last year AG2R rode our clinchers through all the grand tours – with no heat failure on a single wheel,” Aguero said. “And look at how many crashes there were, how many wicked descents there were.”

Reynolds does not have a single metal brake track in their line-up. These are the new Aero series wheels

Aguero said Reynolds’ heat failure rate is “less than 1 percent.”

“I’m not going to say we haven’t seen heat failure, because we have seen them,” he said. “A few people have figured out how to heat fail a wheel. Or, they have used an incorrect brake bad. Like any sport, cycling can be dangerous. Choosing your equipment is important to the level of athlete that you are.”

More so than words, Reynolds’ product line-up speaks for its confidence in carbon clincher technology — there isn’t a single metal brake track in the line-up.

“If you’re slightly squeamish and visiting somewhere for the first time, say you’re coming from Midwest and heading out to an event like [Levi’s GranFondo] for the first time, you probably shouldn’t try a carbon clincher for the first time,” Aguero said. “To me it’s like outlawing aerobars on something like that. It’s a control issue.”

“We believe our carbon clinchers are good for everyone, as long as they have some experience,” Aguero said. “We bet the farm on it.”