Last year I wrote a column outlining some issues with creaky press-fit bottom brackets, and proposed a few tips and solutions to help fix the problem. As another year draws to a close – another year filled with rider complaints about seemingly endless press-fit ordeals – I'm revising my position. Crappy press-fit bottom brackets should not be the end buyers' problem; they are the manufacturers' problem, and it's high time we all send that message loud and clear. If your frame is out of tolerance and causing squeaking, the manufacturer should replace it.

I don't have reservations about the concept of press-fit cups. The idea of a tight, interference fit is perfectly sound. It's been successfully used for many years in bottom brackets and elsewhere, and my personal experiences have generally been quite positive.

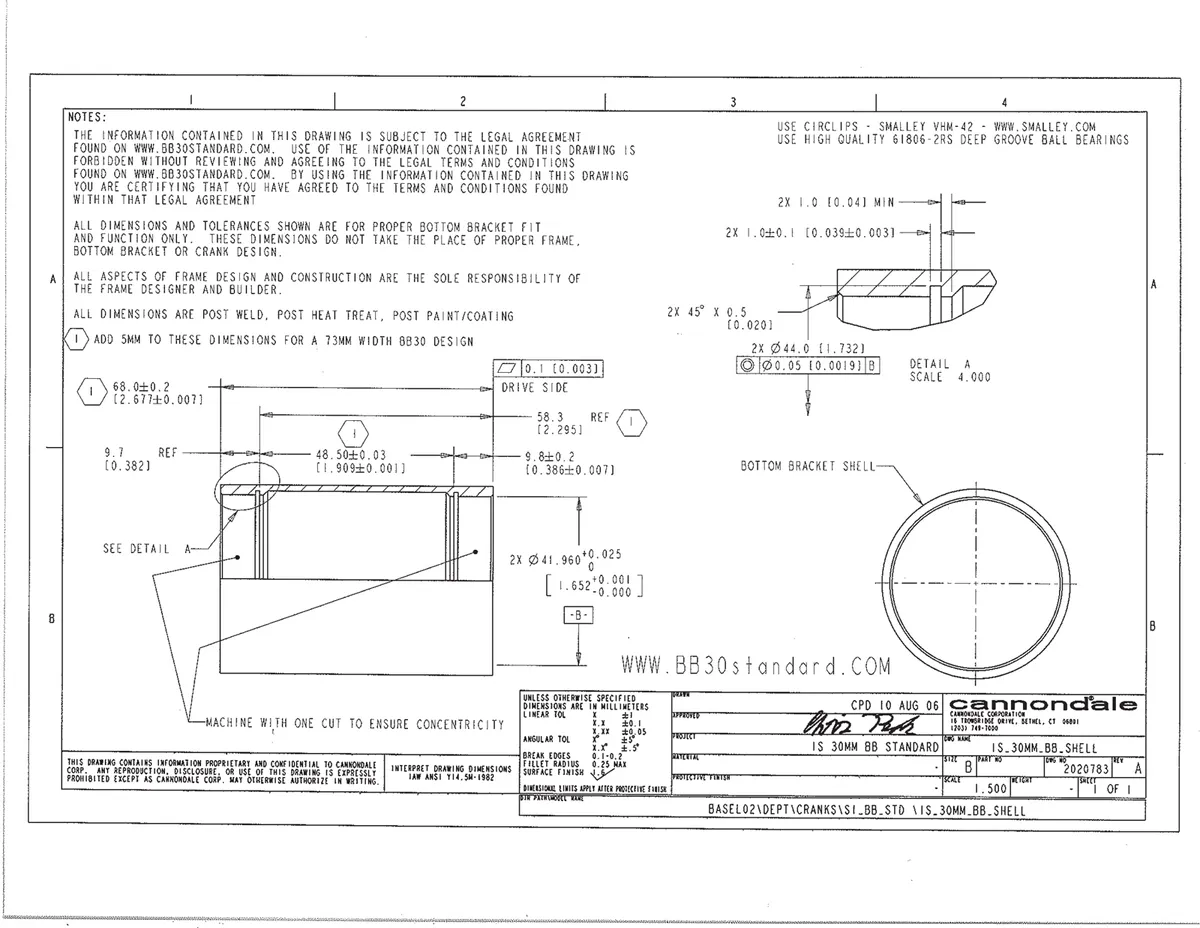

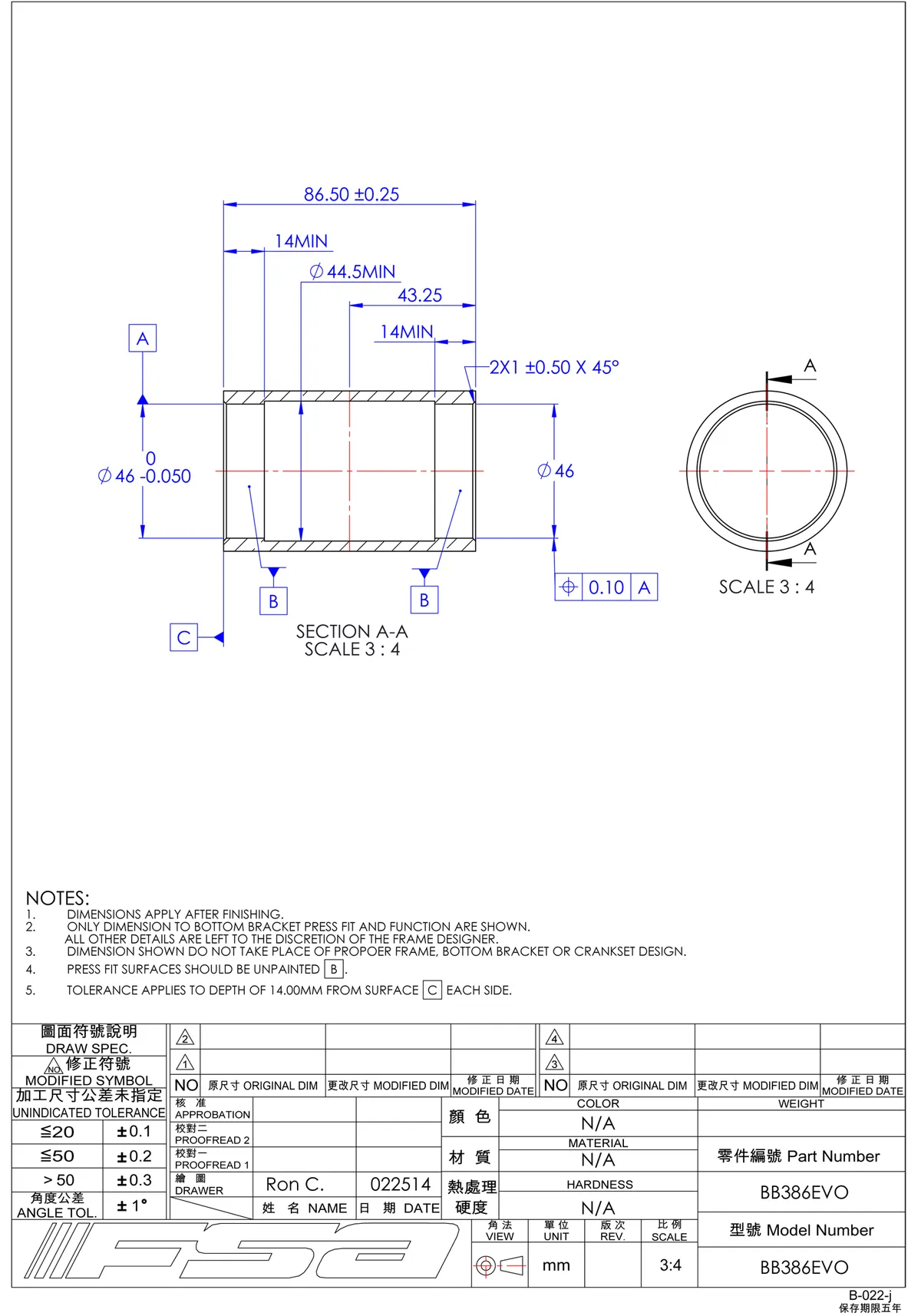

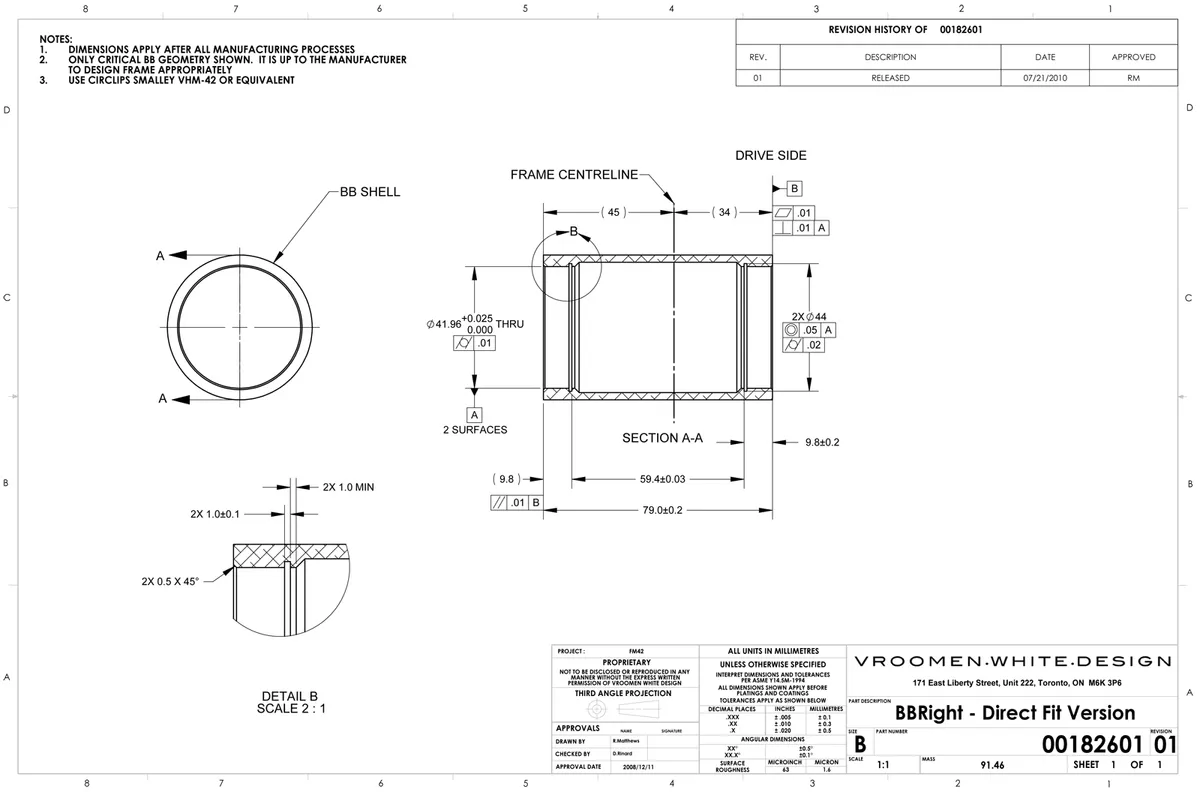

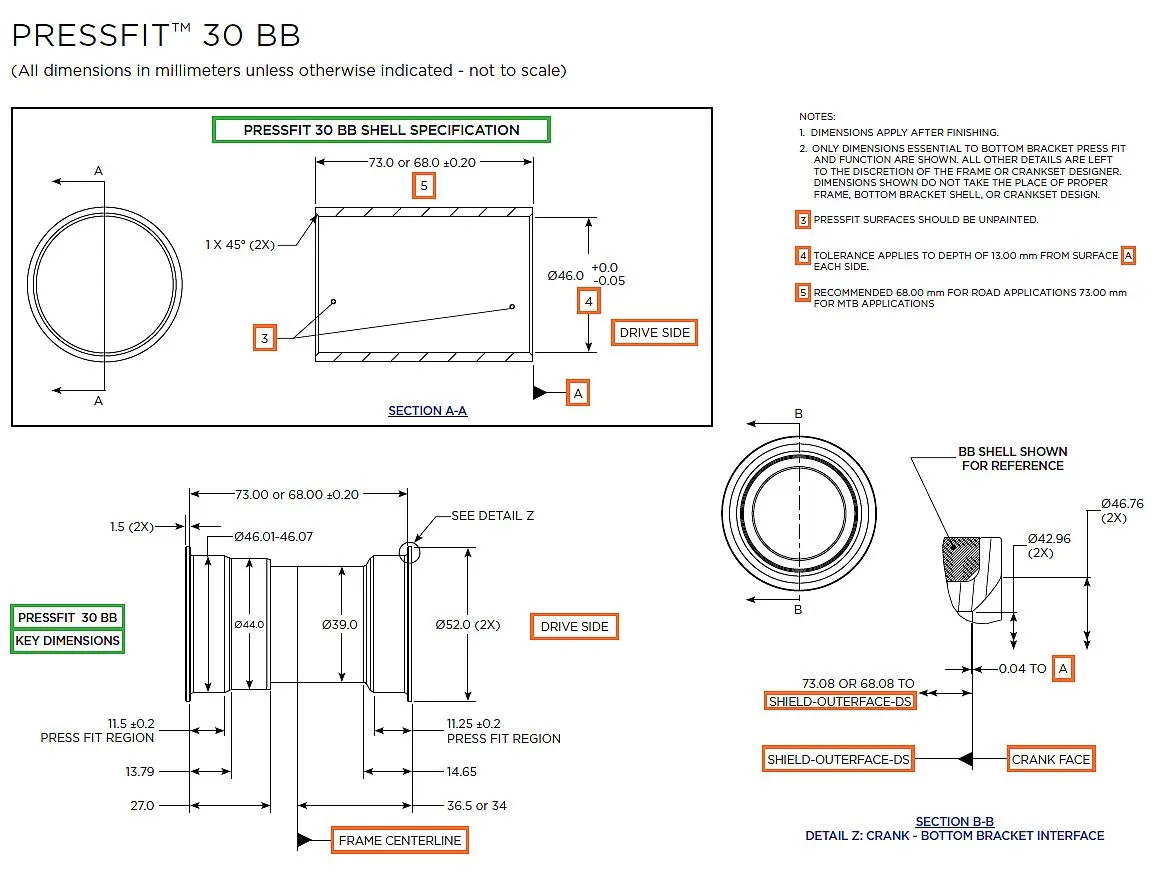

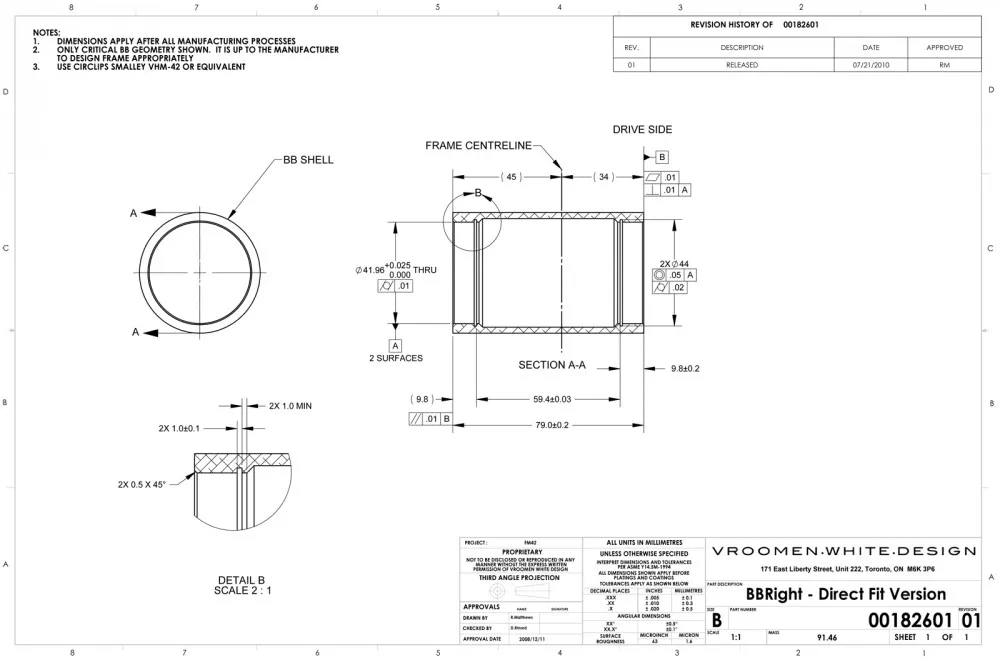

The issue is sloppy manufacturing, loose tolerancing, and quality control processes that are full of holes. If you're one of the unfortunate many who've been plagued with persistent – and seemingly incurable – bottom bracket issues, check to see if your frame is equipped with any of the systems for which I've provided official dimensions below. Then, find yourself some accurate calipers and measure your shell to see if it adheres to those numbers. If it does not, take it up with the frame company.

Related: Complete guide to bottom brackets

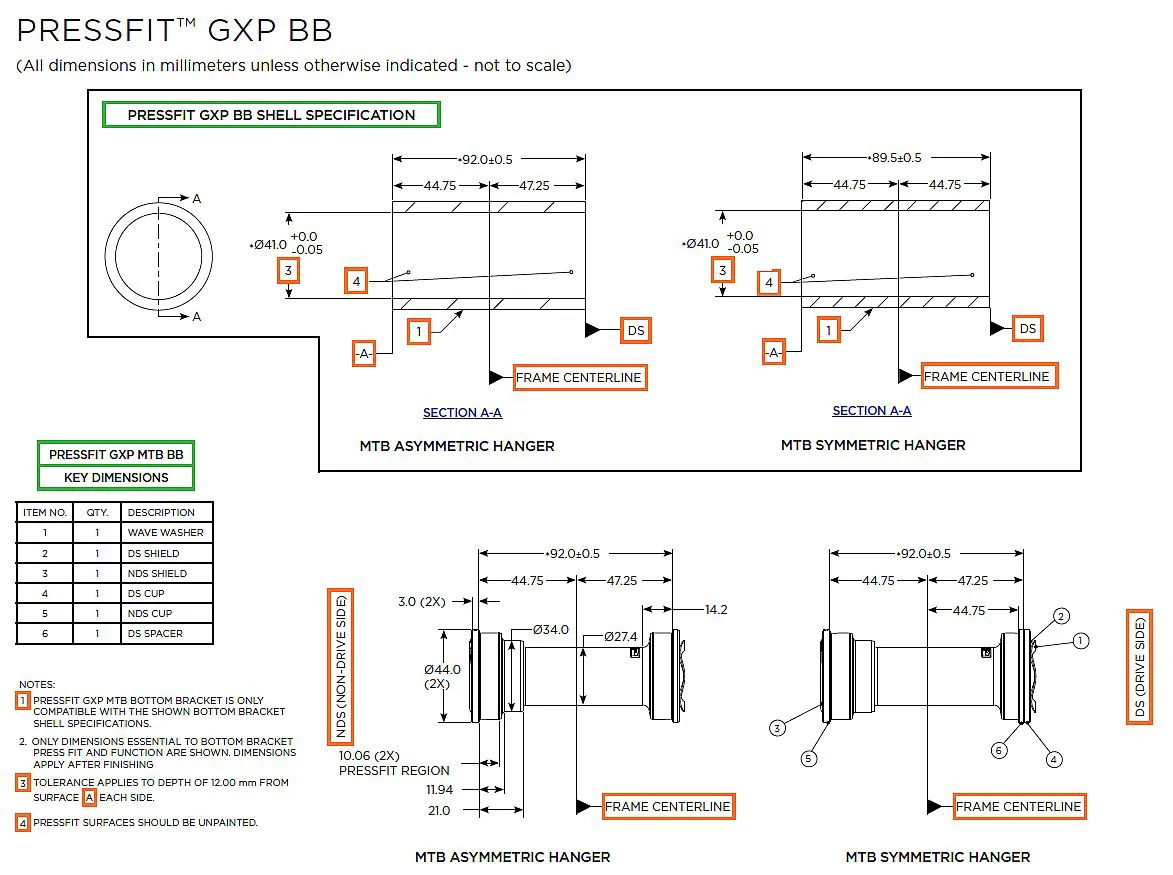

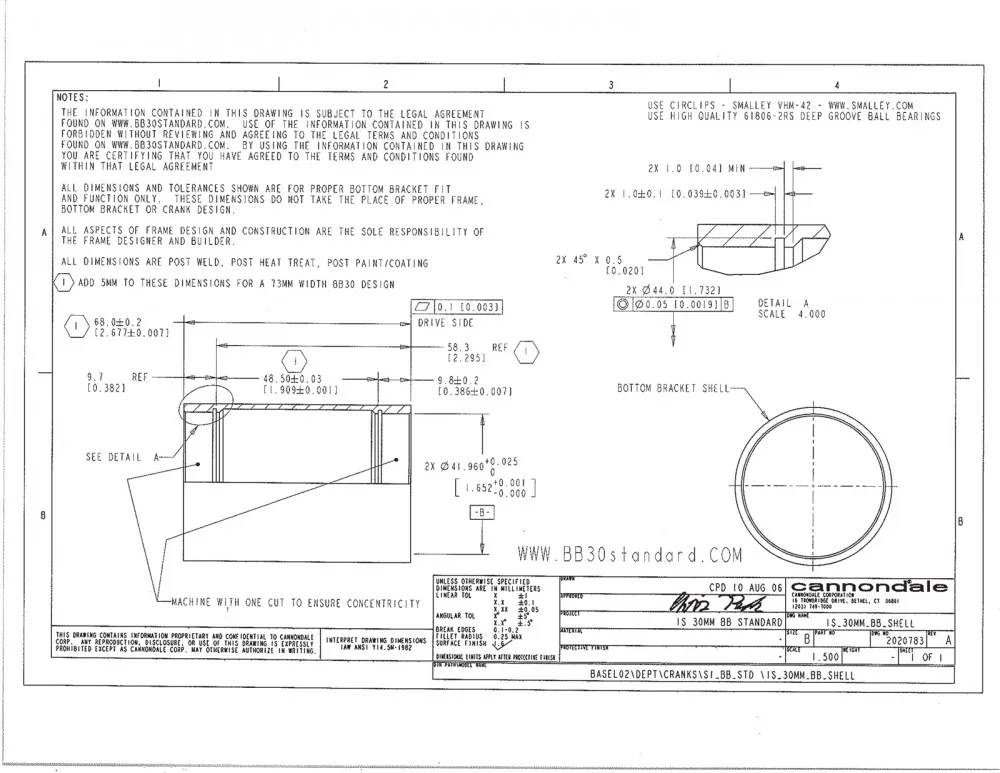

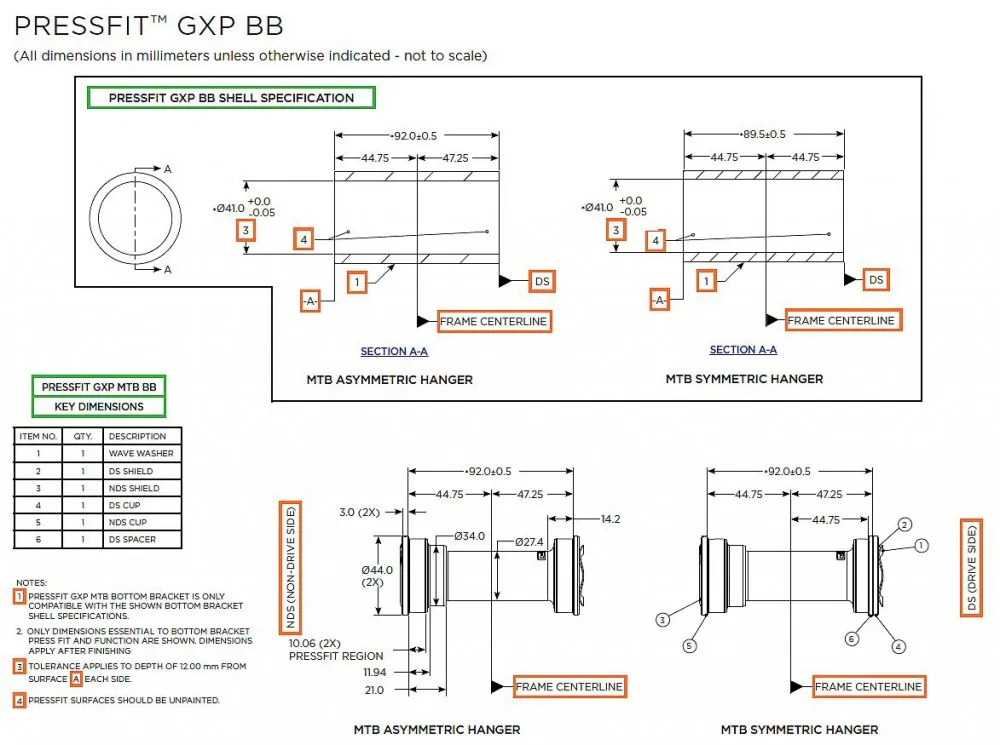

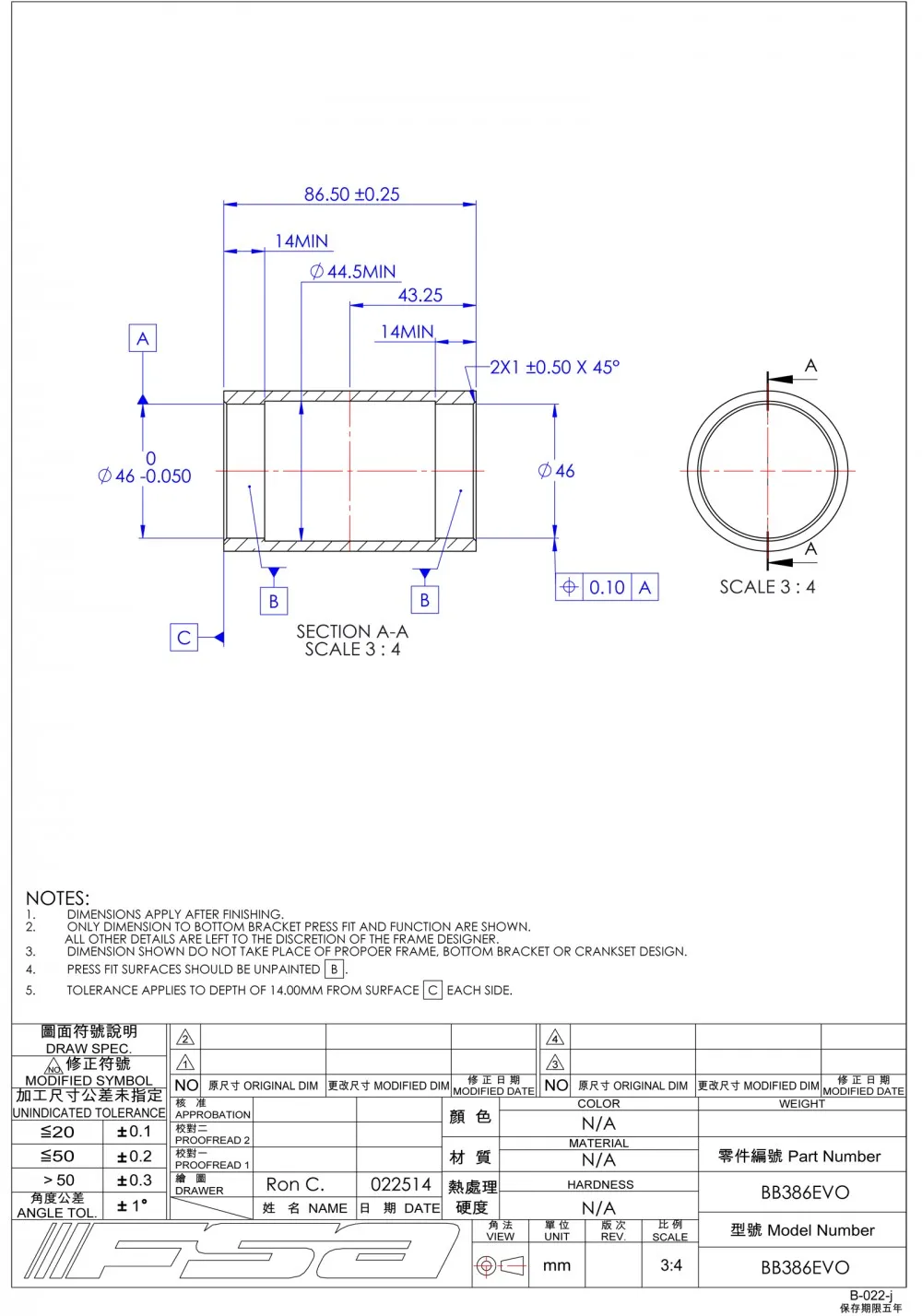

I did a little bit of research and collected prescribed bearing shell dimensions for BB30, PressFit 30, BB386EVO, BBright and PressFit GXP. Trek declined to share manufacturing dimensions for its proprietary BB90 and BB95 designs. Shimano apparently — and surprisingly — does not offer suggested dimensions for its press-fit cups, instead leaving frame builders to figure them out based on the official dimensions of its bearing cups. One would hope that the final dimensions mirror SRAM's PressFit GXP document since the cups are interchangeable.

In many cases, components companies specify precise dimensions for bottom bracket shells

"Shimano does, as indicated in your article, only provide the dimensions of our bottom brackets," said Shimano PR representative Nick Legan. "It is up to the frame manufacturers to determine the best frame dimensions from there. This is because, as I’m sure you know, of the high level of variability with difference frame materials and construction processes."

"SRAM gives a measurement/dimension doc to follow and Shimano does not," echoed Adam Haverstock of Praxis. "So it's all left to subjective interpretation of the engineer/factory to what dimension/tolerance they want to build to. Inherently, some bottom brackets fit better in some frames than others due to this. It's a nightmare to be honest."

Regardless, prescribed tolerances are there for a reason: they guarantee that the end product will function as the designers and engineers intended. In the case of press-fit bottom brackets, the inner bore of the shell should be ever so slightly smaller than the exterior of the bearing cup. Moreover, the left and right bores should not only be round but also concentric and collinear with each other. When all of that works out as it should, what you get is a union of parts that will essentially make the cup one with the frame.

If your frame doesn't measure up as it should, you shouldn't have to put up with it on your own

This sort of thing does happen in real life. The Van Dessel Aloominator aluminum 'cross frameset I tested last season, for example, had a properly bored bottom bracket shell into which I installed a set of stout, machined aluminum PF30 bearing cups from Wheels Manufacturing. The cups pressed in nice and tight (like a Chris King headset in a high-quality metal frame for you fellow mechanics out there) and I had no problems with creaking or bearing durability.

When those tolerances aren't adhered to, however, it sets off a cascade of problems – and the burgeoning crop of patchwork fixes that exist to address the issue highlights how common those problems are. For example, Praxis Works' excellent collet-type adapter bottom bracket expands circumferentially outward against the shell to actively secure itself in place while thread-together designs from Wheels Manufacturing and Wishbone forcibly sandwich the shell in between the cups in an effort to keep them from moving. A more radical design from upstart company BBultimate, on the other hand, sure seems like it'll fix creaking issues but its bonded-in design is semi-permanent and requires an air hammer to remove from your frame.

So there are third-party solutions. But regardless, third-party solutions shouldn't need to exist in the first place if frame manufacturers were doing their jobs properly.

If everything is manufactured as intended, we shouldn't be dealing with creaking as much as we are currently

Frame warranties almost always include a clause that covers "manufacturing defects". If yours falls outside of those guidelines, it's my opinion that your frame wasn't made properly to begin with.

Put another way, you're sitting on a lemon – and in this case, no amount of sugar is going to make it taste good.

So what should you do about it? Demand a correctly made version of what you bought. Given that press-fit bottom brackets are usually touted as a higher-performance alternative to traditional threads, you likely spent a lot of hard-earned money on your bike. It therefore seems perfectly reasonable to me that bike companies should provide what's been promised. If the shell dimensions really aren't what they should be, your bike is defective and you're entitled to one that isn't.

Time to crack out the calipers

This opinion will ruffle a lot of feathers, including bike shop staffers who shouldn't have to waste their time on these sorts of things to begin with, and especially the offending bike companies, whose preeminent goal is often to boost profit while decreasing costs.

Frankly, I'm just over it and you should be, too. Fight back, insist on better, and make your voice louder than that creaking bottom bracket you're so sick and tired of hearing. Send emails, write letters, make phone calls, post to social media outlets and on cycling forums. If you absolutely know you're in the right, be a major PITA until you're heard – and tell them I sent you. Good luck.

James Huang has been writing about bicycle tech since 2005 but also has more than 14 years of experience as a shop mechanic. In that time he's seen plenty of fantastic gear and technology but also a lot of things that flat-out piss him off. You can follow the 'Angry Asian' on Twitter at @angryasian.