It’s fair to say that being a bicycle mechanic can be a difficult job. With a huge list of different maintenance tasks to perform it means that not every day is equal in the workshop.

Here at BikeRadar we had a word with our ex full-time mechanic, Jonny Ashelford, on the things that really yank his crank. With that in mind, here are eight ways to stress out your local mechanic.

1. Bringing in a filthy bike

The last thing a mechanic needs is to be covered in road grime, mud or even worse… a top tube that's still soggy with sweat. Some folk really do need to learn how to clean a bike.

2. Anything that involves internal cable routing

Yep, it might look slightly better but it’s a lot of time and effort for something that offers no real mechanical advantage. A real pet hate of Jonny's is the recent generation of disc-equipped road bikes with hoses that route through the fork.

3. Press-fit bottom brackets

We tried to press (ahem) Jonny further on this topic, but feared he’d get too upset. For an epic rant on press-fit bottom brackets refer back to this brilliant piece, I've had it with press-fit bottom brackets, from BikeRadar's former technical editor James Huang.

4. Chainstay mounted brakes

A nightmare to access and set up, these aero-friendly stoppers sure aren’t a mechanic’s best friend.

5. Tyre and rim combinations that just refuse to cooperate

Fact: some rims and tyres simply don’t go together well and others refuse to work at all, and that's before we add the new-school element of tubeless tyres.

6. TT Bikes in general

From fiddly fairings to the time-consuming assembly of aero bars and the aforementioned chainstay-mounted brakes, the time-trial bike is not a Friday afternoon task.

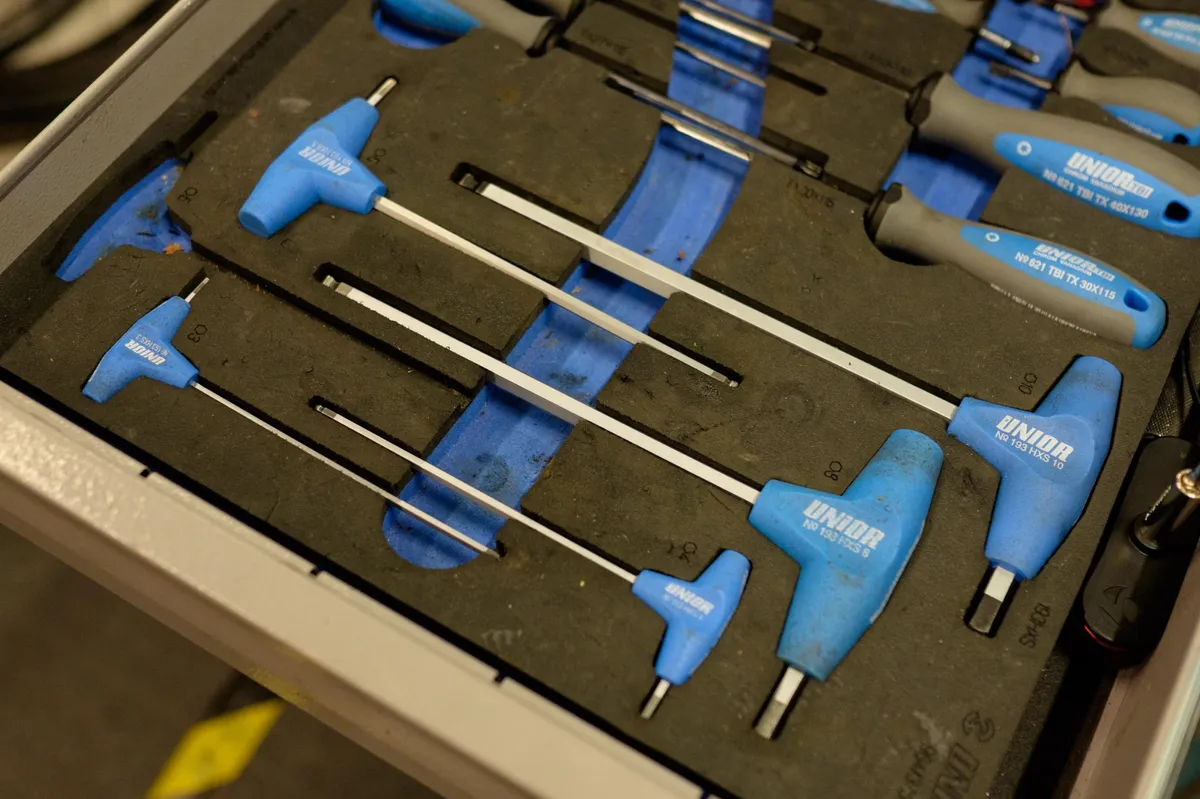

7. Asking to borrow their tools

This one's for those who are lucky enough to work alongside a mechanic. Should you be fortunate to gain access to a mechanic's toolbox, you best make sure you put anything you borrow back where you found it.

8. "Can you just…"

The phrase that precedes a task that's considered both quick and easy… but it never is.

Are you a mechanic? Have you got more to add to this list? Let us know using the comment box below…