More than 20 years after Colnago began carbon-fiber frame production, the Italian company has released the C60 with a few unique design elements, including a “ThreadFit” bottom bracket shell that features a closely-machined steel insert, and soon, a disc-brake model with co-molded dropouts that integrate a caliper mount and a fork with a thru-axle system based on Manitou’s Hexlock15.

Beyond the routine claims of a wider and stiffer frame, there are a few remarkable things going on with the new C60. The family-owned company got a jump on the industry giants in 2012, releasing the first road machine with fully hydraulic braking and electric shifting. That bike, the C59 Disc, also came with mechanical drivetrain options, and featured the same star-shaped tubes as Colnago introduced in 2010.

The C60 blends Colnago tradition with some surprising new twists.

The tradition

Back in the day, ornate steel lugs were a point of pride for craft builders like Ernesto Colnago, whose company built bikes for many of the biggest names in the sport. While some companies retained the modular, plug-n-play technology of tubes and lugs in the transition to carbon, others embraced monocoque or tube-to-tube technology. While Colnago has gone this route with its Asian-made bikes, it has firmly held the line with carbon lugs for its Italian-made bikes like the C60. (Click here to check out some of the amazing bicycles in Colnago's museum.)

“This is our technology, our history,” said Colnago frame designer Davide Fumagalli. “We have some advantages; we can better check the thickness and pressure on all the tubes to ensure uniformity. This is stronger, and repeatable.”

A raceable but comfortable ride has long been a Colnago goal. While some companies have designed some models to be low and stiff with others that are high and comfortable, Colnago has endeavored to make a comfortable race bike. In recent carbon bikes, that means a stout head tube junction, and chainstays that are internally ribbed for lateral stiffness but tapered toward the dropouts for vertical flex.

While some of the design technology is relatively new — Colnago only moved completely to CAD and FEA design for early prototypes with the C59 — the act of building bikes is anything but for the 60-year-old company. Ernesto Colnago got his start with a small bike shop in his hometown of Cambiago, just east of Milan, and quickly moved into building bikes for the likes of Eddy Merckx. Today, the C60 is assembled in the basement underneath his house, which is quite literally just across the street from Colnago’s main headquarters. Some of his employees have been with him for more than 30 years.

The new twists

Colnago, as a man and as a company, realizes that Italian tradition may make for a quaint story, but it won’t make for many sales without a new technology story.

Beyond changes like moving to star-shaped lugs (instead of round ones), and beefing up the down tube 50 percent over the C59, the C60 has some legitimately unique properties.

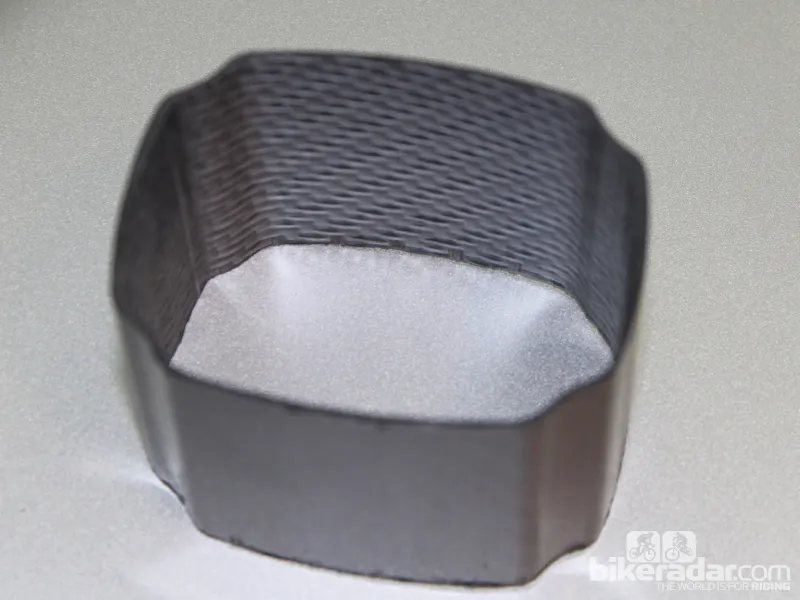

First, the patented ThreadFit 82.5 combines the best of threaded and press-fit systems, Fumagalli says. While press-fit bearings are easy for bike makers to use, critics say the system isn’t as secure or precise as a traditional threaded bottom bracket. This can lead to creaking and/or premature bearing wear.

A threaded C59 BB at left with the new ThreadFit BB on the C60 at right

“We wanted to make something that you can easily renew, and we wanted to avoid making yet another press-fit standard, but we agree with press-fit designers that we can should something larger than a threaded design,” Fumagalli told BikeRadar. “So, we combined the two.”

The end result is a design compatible with all PressFit 86.5 bearings — Shimano, SRAM, Campagno and SRAM — but one with a precision steel-insert fit that can be replaced, if necessary.

“You can machine metal very precisely,” Fumagalli . “With carbon, you can’t manipulate it much beyond what comes out of the mold.”

The C60 will come with the steel sleeve threaded into the frame. In the future, 386 systems will be compatible with a thread-in option.

For Colnago, the design also means that a beefed-up downtube is anchored in a BB shell that’s nearly 50 percent bigger than that of the C59.

The disc frame, which will come out later this year, uses a new two-piece dropout that anchors one caliper post mount, which shaves 140g off a comparable C59 Disc frame. The other caliper mount is bonded into the chainstay.

The caliper fixing bolt mounts to a removable insert, and the two CNC-machined and anodized dropout pieces bolt together.

The thru-axle fork for the C60 is the result of a partnership with Manitou based on the suspension company’s Hexlock15. That thru-axle will simply require a 90-degree turn to secure the wheel.

On the drivetrain side, the dropout has a tidy internal routing solution for electric systems that pops the wire out of the frame just above the axle nut.

The numbers

The geometry carries over from the C59 compact frames. For reference, stack and reach numbers are similar to that of a Specialized Tarmac, which places the C60 between a Trek Madone's aggressive H1 fit and the more upright Madone H2 fit. While the C59 came in compact frames, it was also offered in an astounding 22 traditional sizes, a method from the old days, plus custom. The C60, by contrast, comes in nine compact sizes, five traditional sizes, plus custom geometry options. You can check out the C60 geometry specs here.

The C60 is not a hyperlight bike. A 56cm frame weighs 1,045g. Somewhat confusingly, a compact 56cm frame is labeled 52s for Sloping — Colnago's system for differentiating a 'sloping' compact frame from a traditional 56.

In any event, the C60 rim-brake frame is about 40g lighter than a C59.

While the frame can accept 28mm tires, Colnago officially says it is only fully compatible with tires up to 25mm in width.

Pricing for the frame, fork and seat post is US$6,199. UK pricing has not yet been set.