Time are somewhat of an enigma. With their long heritage in pro racing – the likes of Richard Virenque, Paolo Bettini and Tom Boonen all having had stellar success on board the brand – you’d imagine the huge company producing thousands of bikes. The reality is far closer to that of traditional artisan frame-builders.

The ‘Made in France’ tagline isn’t just a catchphrase – Time frames are produced from the ground up within their French factory, where a small, dedicated team do everything from weaving the carbon to the final paint and polish.

BikeRadar took a look around Time’s HQ in Vaulx-Milieu (on the outskirts of Lyon) and watched every step of the process that takes spools of carbon thread and turns them into some of the finest quality road frames available:

Time factory tour

Time’s in-house design team comprises 10 engineers – one looking after road pedals, one in charge of mountain bike pedals and the remaining eight all involved in the design and development of the carbon frame modules.

Waxing and weaving

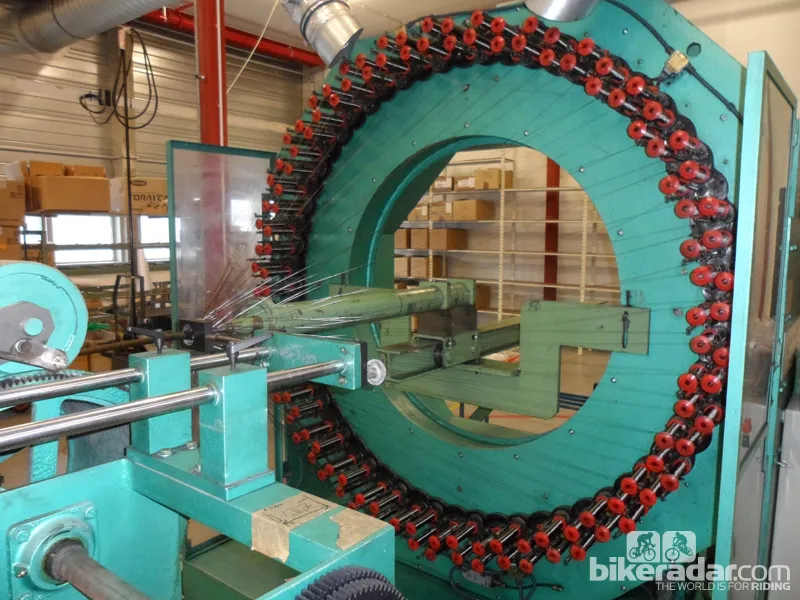

The process starts within the weaving room. Inside are the sort of machines you’d expect to find within a textile factory. Huge circular contraptions take individual strands of fibre that vary in spec between 3,000, 6,000, and 12,000 filaments from as little as 7 microns in diameter.

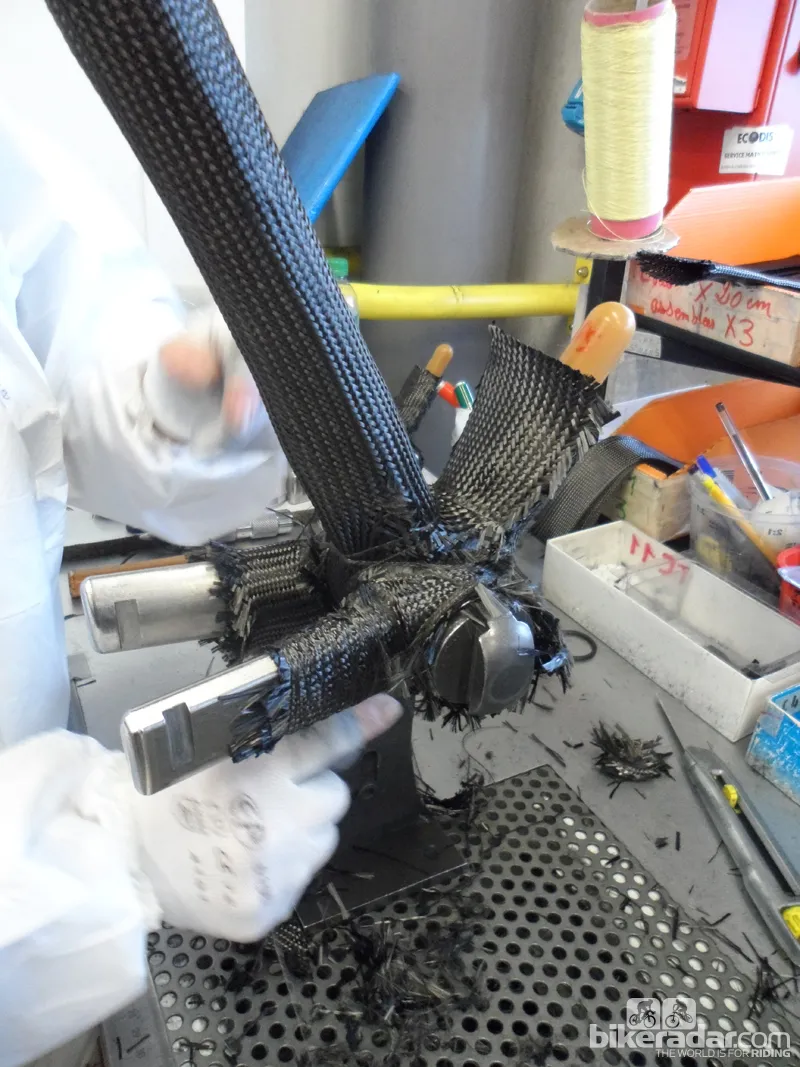

At this point, Time can incorporate other thread materials, allowing the engineers to tune the characteristics of each tube section and frame component. For example, Vectran fibres are incorporated in frame pieces that require a more flexible character. Kevlar is used in areas that need increased protection, such as steerer tubes.

The composites engineers define the exact weave, the orientation of which can be anywhere between 15 and 70 degrees or, in some instances, unidirectional. A 15-degree weave will be highly flexible but very resistant to torsional twisting, whereas a 70-degree angle will be very stiff and flex free but resist twist lengthwise.

Unidirectional orientations resist twisting, too, but are highly flexible. By matching these characteristics to key parts of the frameset, Time can dial in every element of a frame’s character.

Time's engineers can configure the makeup of the carbon tubing

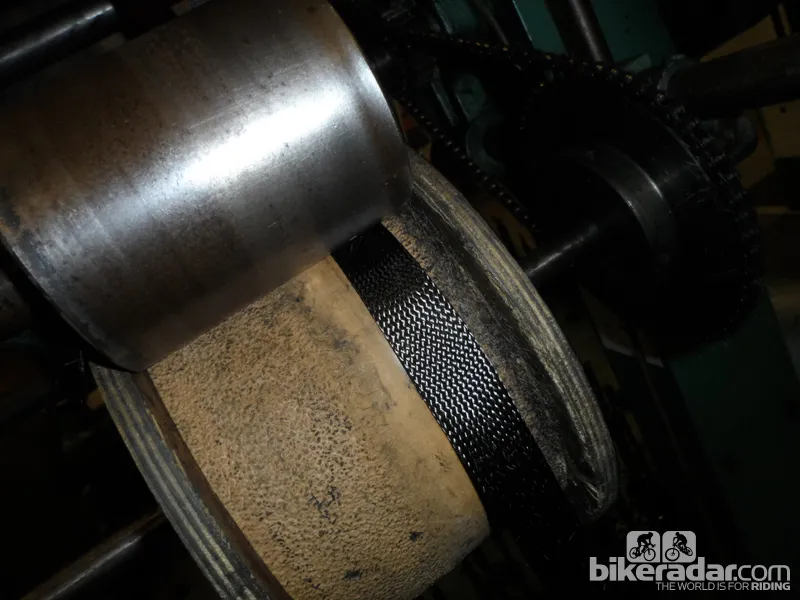

After the woven pieces are created they’re transferred to the cutting room. In here, each tube section is cut to size from the sock/tube forms created by the weaving.

It’s here that the main process – Resin Transfer Molding (RTM) – starts. Each sock section is stretched over an inner mould form made of recyclable wax. Each tube mould has a number of socks stretched over it. The inner mould forms are then connected together, and the fibre ends of each piece are interwoven to make a single structure.

Each section involves complex patterns, with the bottom bracket section of the range-topping VXRS having no fewer than 32 layers! The framesets are all completed with a very thin layer of pre-preg carbon; it’s not there to enhance performance but to make the bikes’ finishes clean. Henri Colliard, Time’s global development VP, told BikeRadar they’ve made special order frames that haven’t had this, which is something we’d definitely like to see.

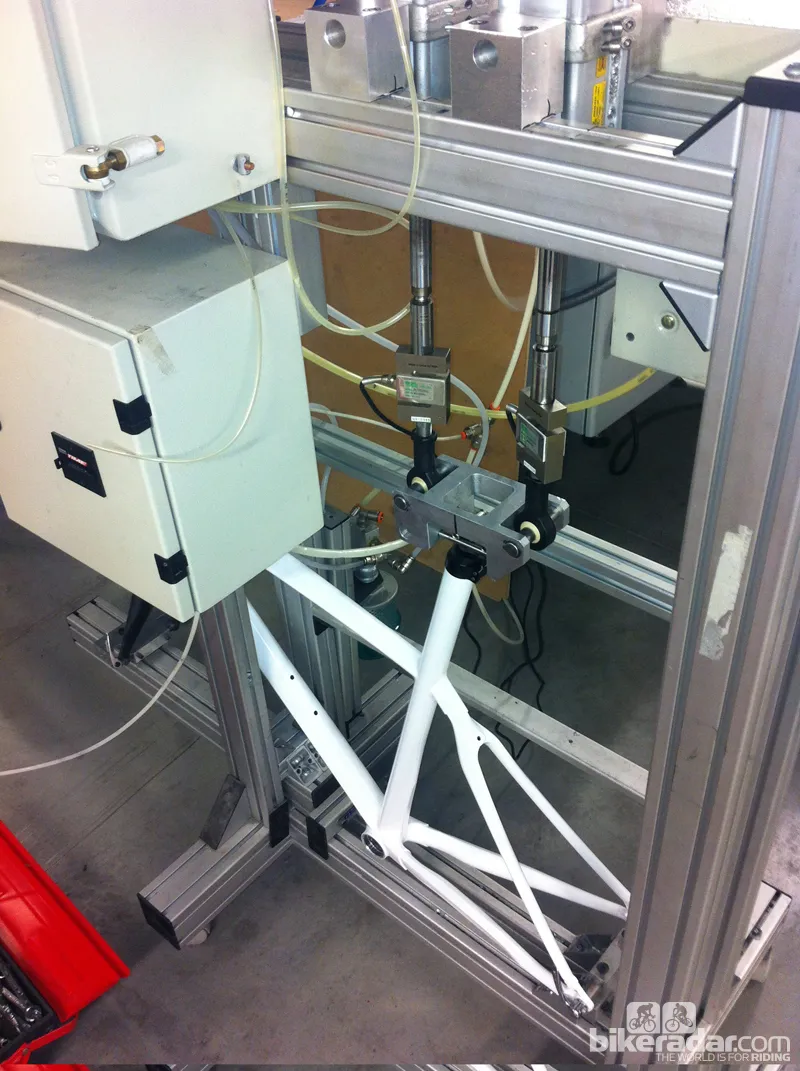

Once the connected wax-and-carbon frame form is finished, it’s time for the resin injection process. The basic frame is put into a precision-engineered mould tool. This has one entry point for the proprietary resin, and three vacuum-controlled exit ports.

Once the mould is pressure-fitted together it’s loaded at an angle, with a constant heat of 100 degrees – just enough to enable the resin to penetrate the carbon and cure, but not enough to melt the wax.

The computer-controlled cage where resin injection happens

800g of resin is injected at a 6 bar pressure, while the three vacuum pumps draw out any air and pull the resin through the raw frame. This results in a totally even spread, and no air pockets or imperfections within. From start to finish, this process takes 20 minutes, with around 15 minutes of prep on each frame – it’s a remarkably swift timescale.

However, the weaving, cutting, pre-mould prep and finishing means that, at full capacity, Time are only able to produce about 70 frames per week. That makes for a pretty exclusive product in these times of mass production.

The final stages

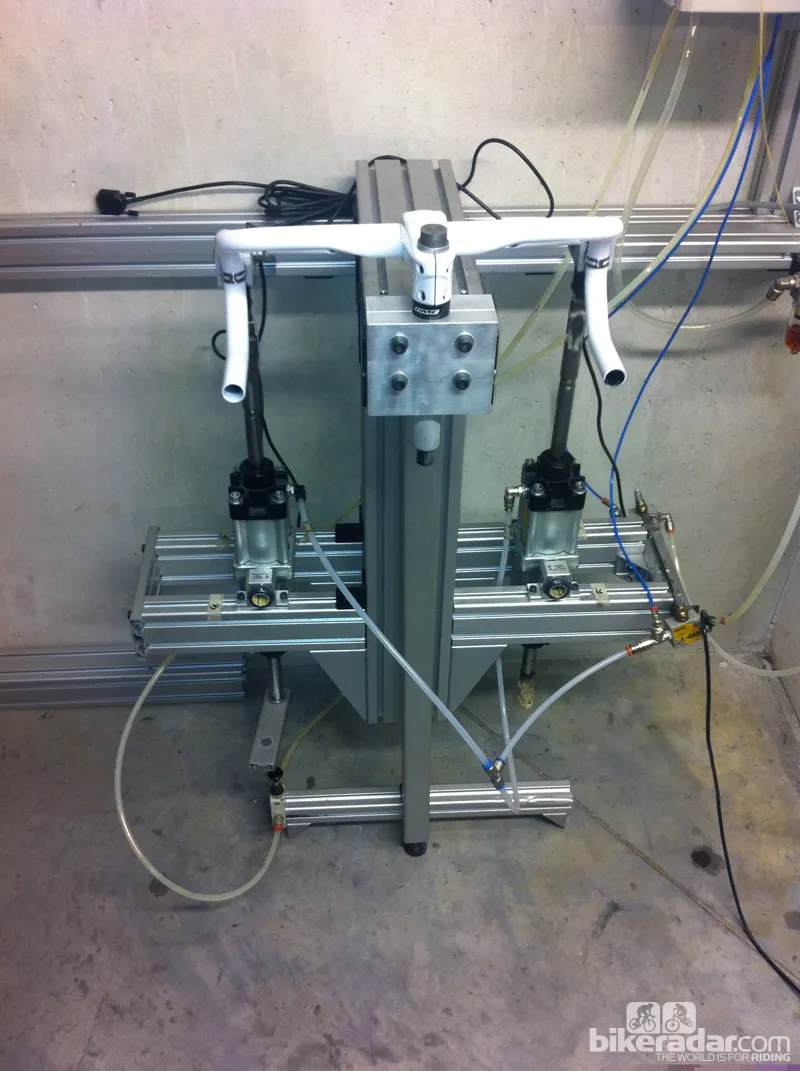

After the frame has been released from the mould, the injection and vacuum ports are removed and the frame has its first clean. It’s left to cure and set, and then it’s off to another oven so the wax can be heated and melted out. From here it’s into the fitting room, where an engineering team use precise jigs to set the bottom bracket inserts, headset inserts and dropouts.

Time’s carbon dropouts are created using a process called Carbon Matrix Technology (CMT), and it’s the one thing in the factory that we were allowed to see but not photograph or video. CMT uses a special carbon matrix made of identical leaves of super-thin carbon fibre pre-impregnated with a resin.

In a temperature-controlled room, these pieces are chilled to -18 degrees to maintain density. These flat sheets are then coiled up like a Swiss roll and forced under 10 tonnes of pressure for 350-600 seconds, to form a complex one-piece mould.

Time use this process for dropouts but also for the Integrated Seat Post (ISP) seat clamp base, stem and stem plates too. CMT creates a highly dense yet super light and very strong part. The carbon dropouts, for instance, weigh just 11.79g, much less than identical ones made from aluminium (16g).

The process needs great care and attention so, each and every day, the flat pieces have to be prepared by hand to ensure no variances in temperature – this stuff has a pretty short shelf life.

Every inch of every frame is checked for the most minor of imperfections

As soon as the pieces are extracted from the moulds, they go through quality control; weight wise, if they’re not within 1g they’re rejected. The process is totally unique within the bike industry, and outside only the likes of Boeing are employing it.

With the component parts bonded in and every element and alignment checked, the frames then go through their final finishes. Each one is hand-completed (finely sanded) and takes 45 minutes. The painting and decal process can go on for more than 10 hours for one of Time’s VIP bikes, and takes place in a special dust- and dirt-free series of rooms.

In an industry that’s full of marketing hype and claims about the humble bike’s creation, it’s great to see that Time can actually back up their story with a frame production process that combines the cutting edge with true handbuilt quality.

For more information on Time products see www.time-sport.com.