Eugene, Oregon builder Rob English is on a mission to prove that steel can still be used in ultra-high-performance bicycles when properly designed and engineered. While some of his creations look almost impossibly minimal, English insists they're structurally sound. Attendees at the North American Handmade Bicycle Show certainly found them visually stunning.

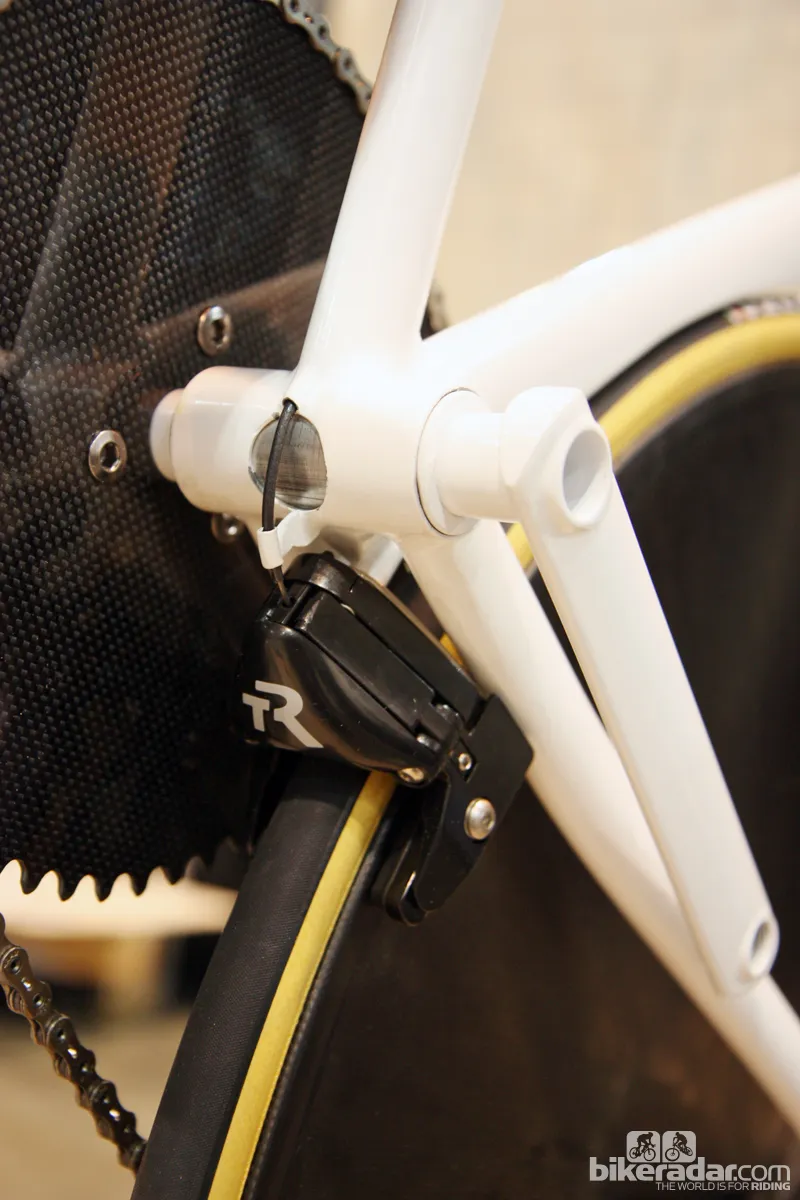

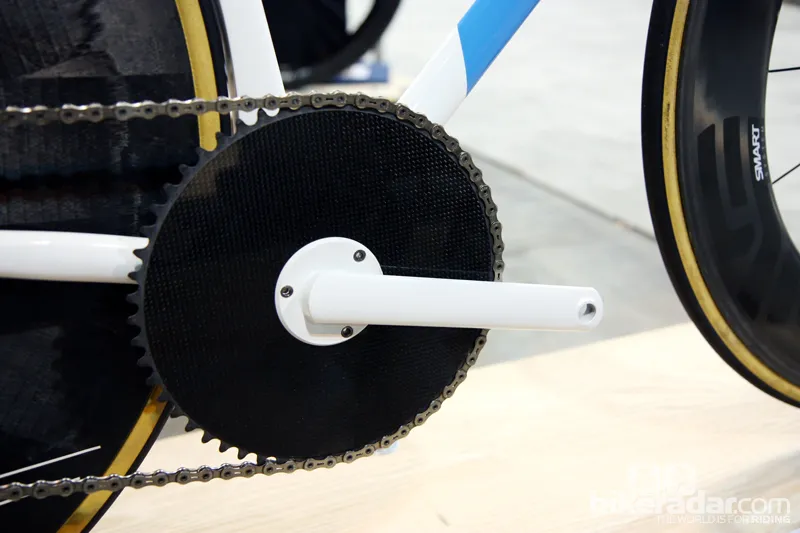

The star of the English Cycles booth was arguable English's new personal time trial machine. After several years on the previous iteration, English decided it was time for a new one and it's a clear showcase for his abilities. Save for some of the components (such as the TriRig rear brake, Dash Cycles rear disc and saddle, Enve front rim and Shimano Di2 bits, for example), everything else is fully custom using aero-profile chromoly tubing sourced from an airplane supplier.

Tiny angular bearings are used for the headset

The front end is highly integrated with the fork, steerer, stem, base bar and extensions all welded together into a single assembly. The aluminum front brake was machined by English, too, and the outer pods and brake levers are borrowed from USE. Incredibly tiny angular contact headset bearings keep the maximum width of the front end to under 18mm.

The bespoke theme continues on to the chromoly crankset, which rotates on three cartridge bearings pressed into the shell and features a split spindle that bolts together in the middle. The front hub – also machined by English – uses incredibly narrow spoke flanges, also to minimize frontal area. Mounted to the end of the extensions are custom Di2 buttons.

All in, English says his new TT bike weighs about 7.7kg (17lb).

English also decided it was about time he started riding a geared mountain bike again and built himself a gorgeous steel 29er to suit. Twin top tubes arc seamlessly from the head tube to eventually become the seat stays while the seat tube is also curved to allow for shorter chain stays.

Up front is English's trademark one-piece stem and steerer setup, which extends down through the head tube and is clamped at the rigid fork crown. Gracefully miniscule post mount brake tabs are used front and rear and the chain is secured on to the dedicated single ring by a custom machined Delrin guide that's bolted – not clamped – to the seat tube. As shown, English says it's about 8.6kg (19.0lb).

English's trademark one-piece stem and steerer inserts into the head tube

At the other end of the booth sat a far burlier machine built for the owner of custom bag maker Black Rainbow Project, who plans on tackling the Great Divide mountain bike race. This 29er was laden with a front rack – curved to match the bag, of course – heaps of bottle cages, and a custom front triangle bag secured with braze-ons, not straps. The English-built handlebar setup includes a tidy aero position, too, that English claims leaves more breathing room than traditional bolt-on setups.

Speaking of bolt-on, English also designed this bike with a removable rear triangle. This eases transport, of course, but also allows use of a Gates Centertrack belt drive. Should the Shimano Alfine rear hub go down, the front hub uses 135mm spacing, too, and is fitted with a single Centertrack cog just in case.

We could go on and on, but at this point you're probably tired of reading and just want to see the pictures. Sit back and enjoy the gallery at the above right.

A bike built to tackle the Great Divide mountain bike race