The most ornate machines at NAHBS employ classic construction methods that become canvases for builders to showcase their artistry. When it comes to material, it’s without exception that traditional steel still rules the floor.

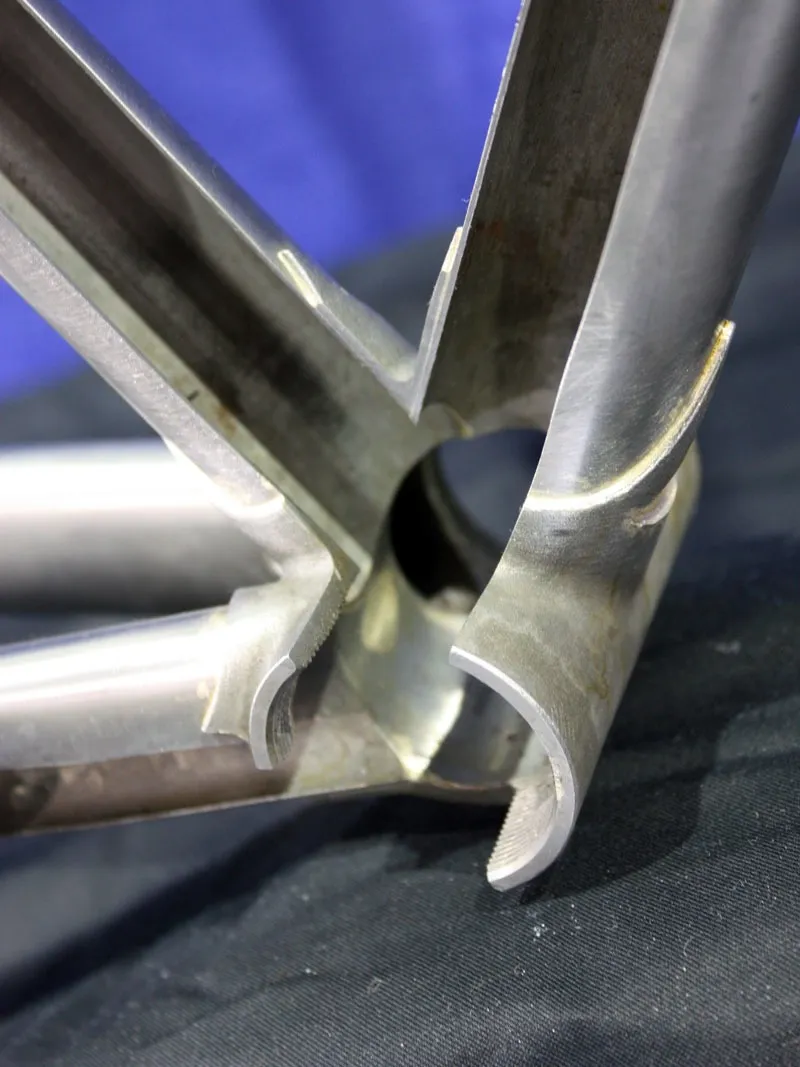

Simply put, lugged and fillet brazed construction offers a massive amount of creativity in forming a joint and this is what many builders want to exploit. The joint itself often becomes the highlight of a lugged or fillet brazed frame – and not just from a functional perspective. Hours of hand carving can go into a single lug while the pinnacle of a fillet brazed joint seems to be when it is altogether seamless and invisible. While TIG-welded bikes can be just as artistic, they’re firmly based in function, which some might find stifling.

Recently the traditional construction methods benefit from the advancement of steel metallurgy. It's no accident that representatives from Reynolds, Columbus, Dedacciai, and True Temper were all on-site at NAHBS, where a hot trend continues to be stainless alloys that not only lend themselves to lighter frames, but ones that are also much more resistant to corrosion so they can be brushed or polished, too.

"We've actually extended the range of 953 further so we now have the ability to do slightly thicker walls which allow people to do mountain bikes," said Keith Noronha, managing director at Reynolds Technology Ltd. "Although we haven't released them yet, there are also some 953 fork blades around at the show as well."

Reynolds has also developed a newer stainless alloy called 931, which is more akin to 853 in terms of strength but is easier to draw into smaller tubes. Noronha says this will be developed into a range of seat- and chain stays so that builders can construct full-stainless frames. Testing has already shown that it can be readily brazed into lugs and early reports suggest that it can also be welded to 953 tubes, too.

Columbus recently returned to the stainless scene with its new XCr tubeset, currently available only in TIG-specific butting profiles, but soon to be offered in a lug-appropriate set. As compared to the company's old Metax tubeset, Mauro Mondonico of Columbus, who also happens to be the son of the famous framebuilder, says XCr is more reliable, too.

In spite of stainless's appealing properties, not everyone is convinced stainless is the way to go. Longtime framebuilder Ben Serotta, whose Colorado Concept frames arguably pioneered the age of radically shaped steel tubes, is not a fan.

"Whatever [stainless] alloy you have, it is somewhat more brittle and it's harder to manipulate," he said. "The one advantage that it has is its resistance to corrosion but it's not corrosion-proof. In terms of ride performance, we can deliver a higher performance ride using other steel alloys."

Still, tubing suppliers such as Reynolds emphasize the critical role small custom builders play in the development of new materials. They aren't bound by massive quantities and buy-ins since they operate in such small volume, their skill level is typically much higher than the industry average and they generally have a better sense of how the industry is trending in terms of customer needs and wants.

"We're first working with the custom builders because they're the important guys in terms of how it works, what it works with and all the rest of it," Noronha said. "We like to talk to the custom builders first because it literally shapes what we're going to offer to our customers moving forward."

It’s this sense straight from the grassroots that will keep steel, whether lugged, brazed or welded, real for years to come.