Tucked inside a small industrial complex in Nastola, Finland is the nondescript grey building that's the base of independent third-party tire testers Wheel Energy.

Using a battery of purpose-built machines, founders Petri Hankiola, Veijo Pulkkanen and Marko Savolainen are addressing some of the common questions surrounding bicycle tires. They're coming up with some interesting answers that no longer have to rely on word of mouth, tradition or intuition for their veracity.

Take these conclusions for example:

Puncture-resistant belts work but they're not created equal: Nylon, aramid and other belts placed under the tread do help ward off flats but there are benefits and trade-offs to the various materials. Tougher ones like aramid are durable and highly cut- and puncture-resistant but their stiff nature sucks up a lot of energy, contributing to rolling resistance. More flexible ones like nylon aren't as bulletproof but offer a better compromise if you still want to retain good performance.

Wider tires roll faster than narrower ones: Riders have argued for years that narrower tires – especially on the road – roll faster and are more efficient than wider ones when in fact, the opposite is true. According to Wheel Energy, the key to reducing rolling resistance is minimizing the energy lost to casing deformation, not minimizing how much tread is in contact with the ground. All other factors being equal, wider casings exhibit less 'bulge' as a percentage of their cross-section and also have a shorter section of deflected sidewall.

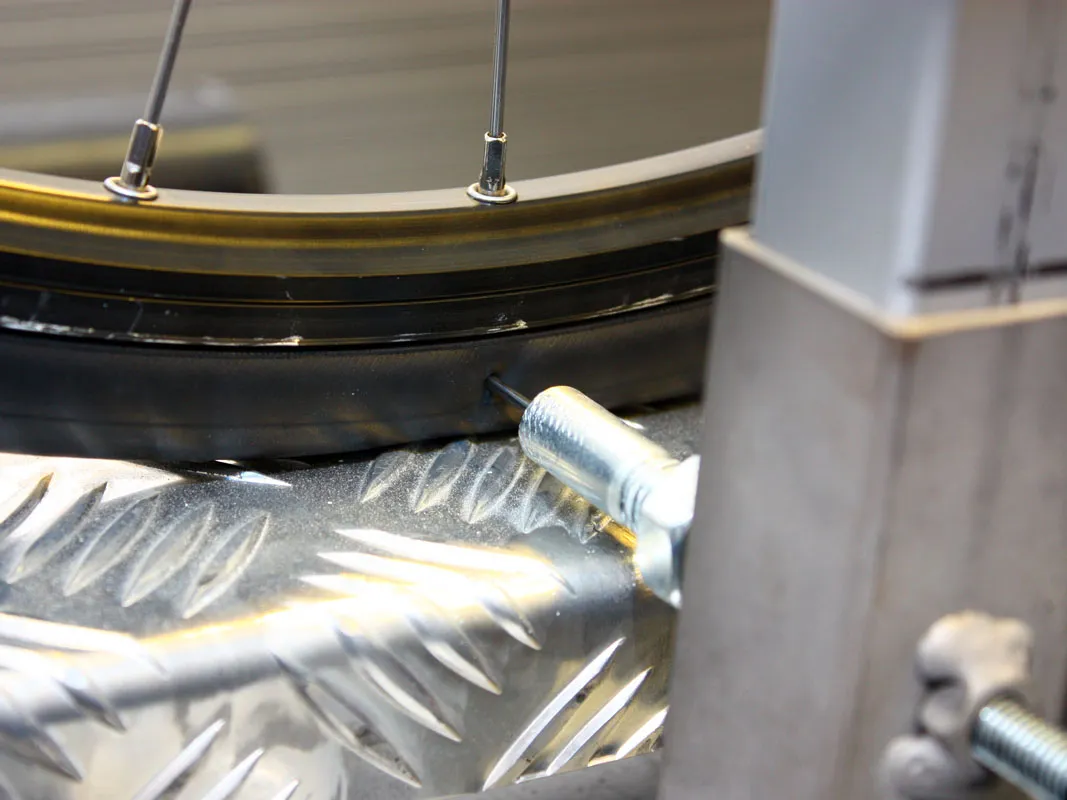

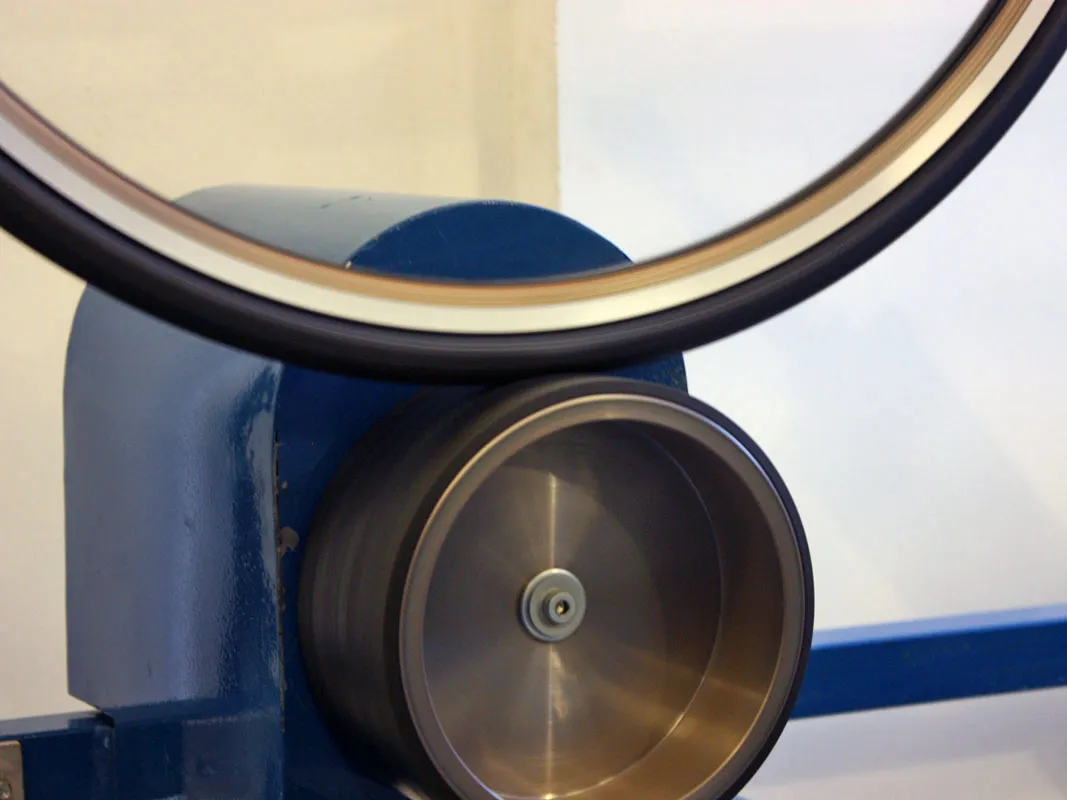

To test rolling resistance, tires are mounted on control wheels and applied to the rotating drum with hydraulically controlled pressure

How big a difference are we talking about here? For an equivalent make and model of tire, Wheel Energy claim the 25mm-wide size will have five percent lower rolling resistance on average – the supposed average limit of human detection – than the more common 23mm one. However, 23mm and narrower tires do still have the advantage when it comes to aerodynamics, and to a lesser extent weight. If you're selecting a tire for drag strip time trials, narrow is the way to go, but if you want a better handling tire for road racing and crits, go wider – particularly for rough road surfaces.

Inner tubes matter: Think there's no point in that expensive lightweight tube? Think again if you're trying to go faster. According to Wheel Energy's data, latex tubes roll 10 percent faster than common 0.6mm-thick butyl tubes, though today's ultra-thin butyl models come admirably close.

Larger diameter wheels roll faster than smaller ones: Yep, it's now been confirmed in the lab – 29er mountain bikes roll faster than 26ers. Wheel Energy say the effect here is similar to that of tire width, in that larger-diameter tires exhibit less casing deflection and thus less energy loss. In the case of 29ers, there's the additional factor of the 29in wheels' lower angle of attack for anything other than a perfectly smooth ground surface.

Tires are controllably compressed on the translucent surface of this contact patch test station and then photographed from below

The longer effective lever requires less energy to overcome whatever tire bulge exists at the contact patch so more forward momentum is maintained. In addition, Wheel Energy's analyses of tire contact patch have confirmed that 29in tires don't have a bigger footprint than otherwise identical 26in ones. While the total area is the same, the shape of the patch is longer and narrower on 29ers, though.

Tread pattern matters, even on the road: The importance of tread pattern is no surprise to the off-road world but common wisdom says it's a non-factor on the road, where slick treads are assumed to deliver the greatest surface contact with the ground and thus, the best grip. However, asphalt is far from a perfect – or even consistent – material. Certain tread designs can provide a measureable mechanical adhesion to the ground.

Higher thread counts aren't always better: According to Wheel Energy, higher thread count casings are generally lighter and suppler than tires with lower thread counts since they absorb less rubber during the vulcanization process (non-vulcanized tires such as most high-end tubulars exhibit their own characteristics). However, they also suffer from decreased puncture resistance since the individual cords are thinner and easier to cut.

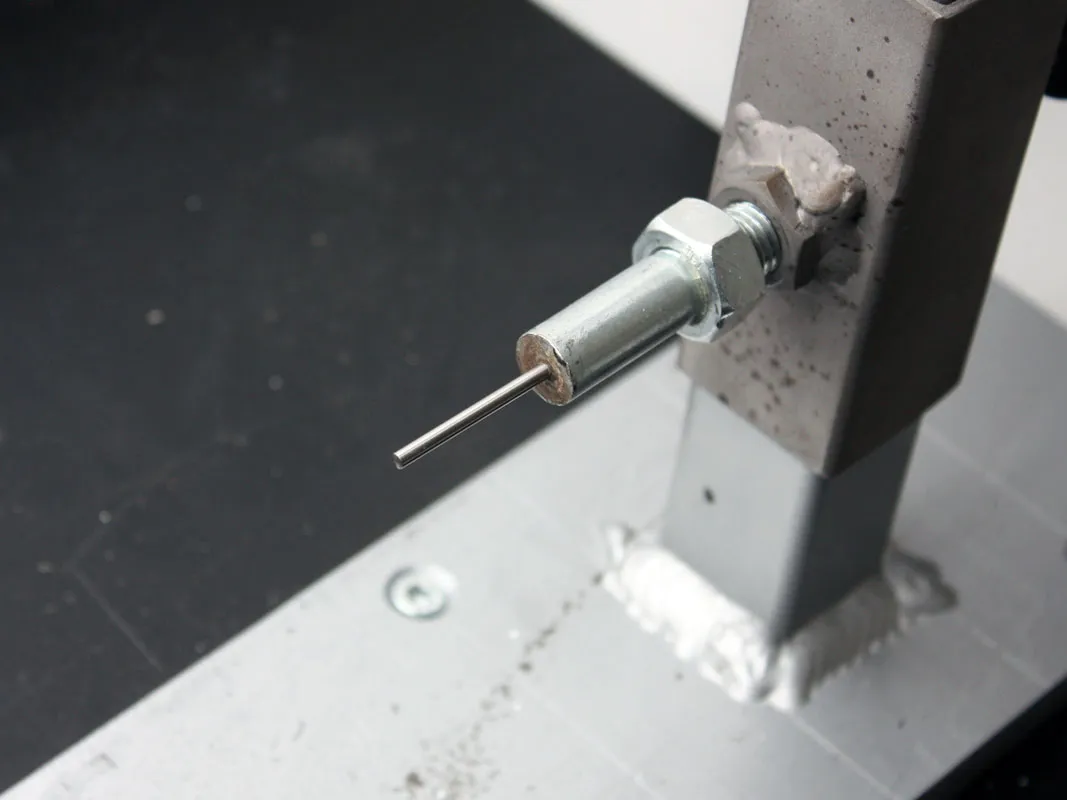

Tire friction is tested by controllably moving a small section of road material against a stationary wheel

Wheel Energy claim medium-count casings (around 60tpi) may offer the best all-round performance for everyday use. As compared to 120tpi casings, they can actually roll faster and are much more resistant to cuts while often carrying just a slight weight penalty. If cut resistance is highest on your list of priorities, 30tpi tires are apparently the way to go but you can also expect them to be heavy and slow rolling.

How they do it

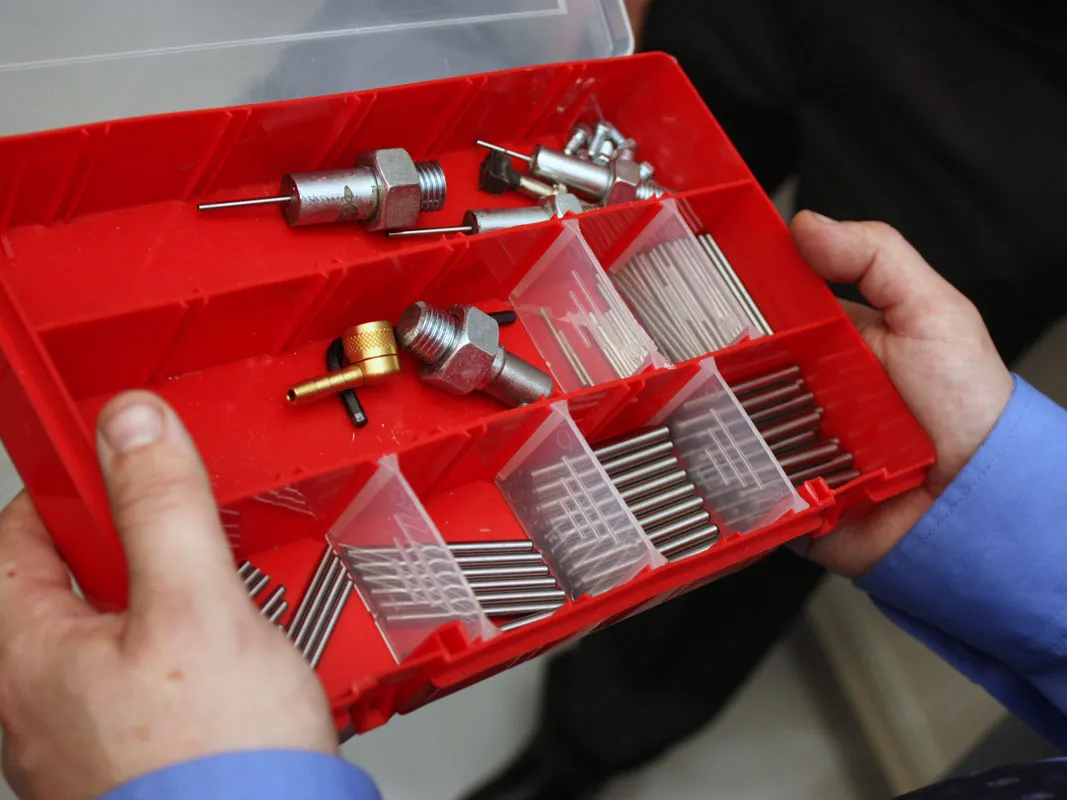

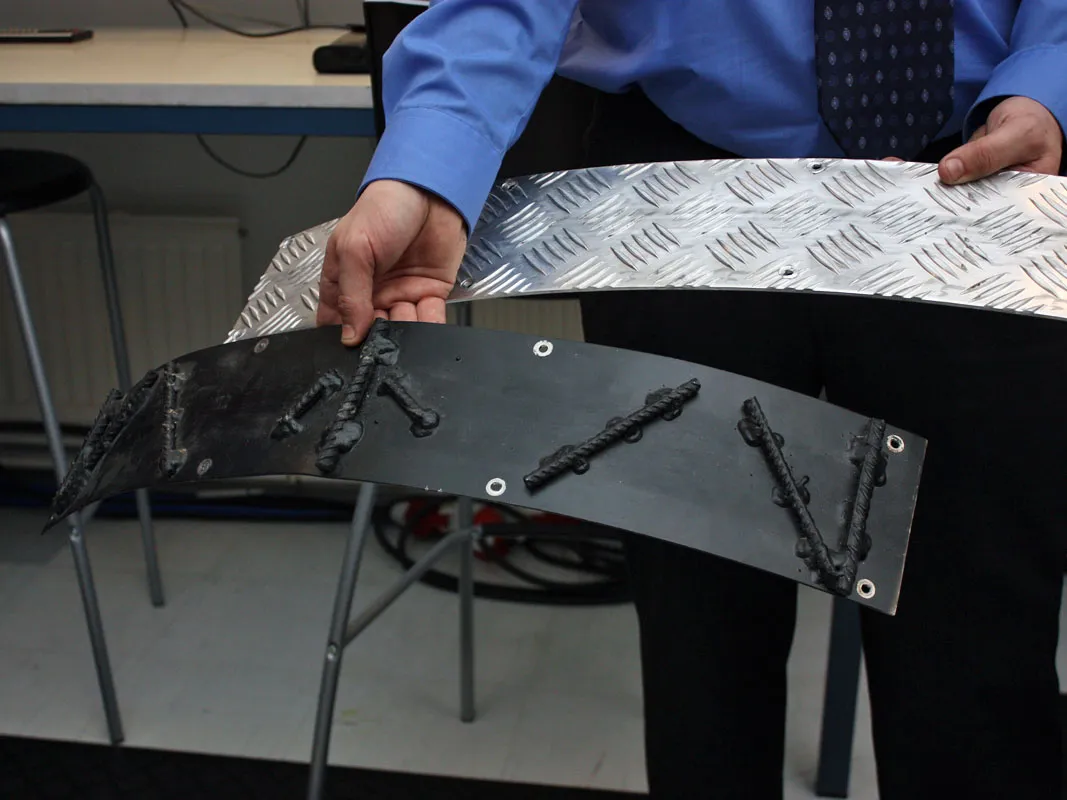

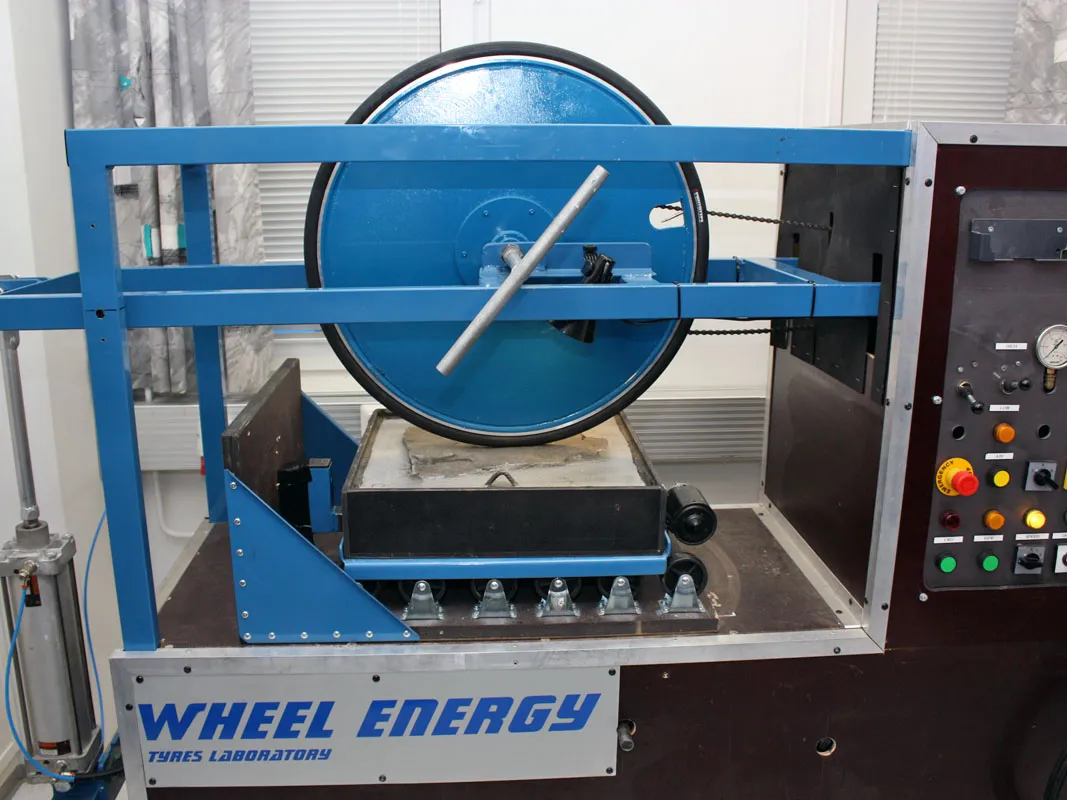

Wheel Energy's constantly evolving collection of testing machines are no miracles of design innovation or elegance but the fact that they exist at all is noteworthy in that, as far as we're aware, it's the only independent test facility of its type in the world. There are dedicated stations for rolling resistance, crown and sidewall puncture resistance, friction and contact patch characterization, with additional apparatuses being designed and built as necessary.

Each machine is fully custom designed, built with computer controlled hydraulic loading and fitted with industrial load cells for precise and accurate measurements. Rolling resistance tests are conducted on large-diameter drums with various types of surface treatments, friction tests are done with a wide range of ground types (asphalt, concrete, etc) and puncture tests can be performed using interchangeable tip sizes and radii. Conditions are kept constant throughout to foster repeatability.

Water is applied to the tires to simulate wet-weather traction

Why it matters

Tire development can be a notoriously black art and with development cycles reportedly taking around a full calendar year for a single model, it's easy to lose an entire model year if something goes awry. And once a mold is cut, it's more or less a done deal whether or not the tire is actually any good. That's why companies such as Specialized, Trek and Vittoria (and whoever else is willing to pay) now commission Wheel Energy to provide valuable data to aid the process.

Specialized are especially open about how Wheel Energy's information has improved their range – and exposed the flaws. By Specialized's own admission, the company had been falling behind in recent years in the tire market – where, ironically enough, they first got their start in the industry back in the late Seventies. In particular, they say tests on their previous-generation S-Works Mondo road flagship showed a whopping 25 percent more rolling resistance than most of its competition. Ouch.

That's supposedly all changed now. Thanks to data from Wheel Energy, Specialized tire product manager Wolf vorm Walde claims the Mondo's replacement, the Turbo, is on-par with the rest of the high-end road tire market in terms of rolling resistance. Among the changes are reduced rubber around the shoulder of the tread and reduced rubber thickness in the casing, both of which help minimize the amount of energy lost in casing deformation as the tire rolls down the road.

Wheel Energy keep a number of real-world samples of road surfaces on hand to provide more useful data

In the case of Specialized's revamped Roubaix clinchers, it was also found that sidewall puncture resistance could be improved without hampering rolling resistance by simply increasing the casing ply overlap in that area. Based on our initial test rides on a pair of pre-production samples, we'd say that data has been put to good use as they feel notably lively for tires that aren't necessarily intended for racing. In fact, they're perhaps even better than Specialized's previous-generation Mondos, though we need to put more testing time in before drawing any firm conclusions.

If other Wheel Energy clients can make similar improvements in efficiency, both in terms of tire development and performance, then ultimately we all stand to gain in terms of the quality of tires on the market as well as the pace at which they improve – not bad for a nondescript little grey building in the middle of the woods in Finland.