Cycling’s technical evolution from steel frames, woollen jerseys and steak breakfasts to the isotonic mix of carbon composites and electronic gear shifting that we see today has been driven by men far removed from the flashbulbs of the podium.

In an unassuming industrial park in rural Norfolk, engineers renowned for constructing and honing Formula 1 and rally car components are pushing cycling into uncharted territory. BERU f1systems have brought together virtually every available measurement of rider performance to create a professional training tool leaps ahead of anything the cycling world has even envisaged.

On its release, the radical design, bespoke manufacture and £25,000 price tag of BERU’s Factor001 made waves through the cycling world and into lifestyle magazines. But by focusing on those aspects, that initial coverage almost totally missed the point. The measurement technology is the true heart of this project – the Factor001 is a bicycle capable of unravelling the threads of data that form the fabric of a perfect race.

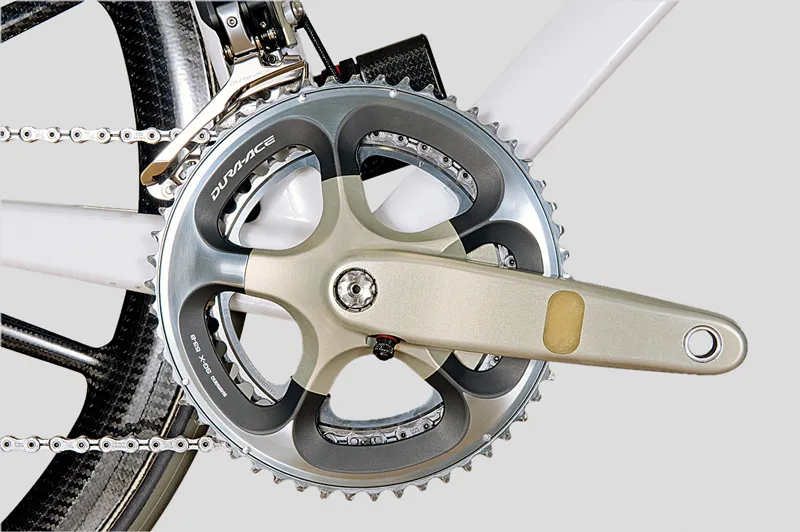

So, is this sensor-saturated superbike the future of bicycle training? Despite aiming to break free of cycling tradition, the familiar measures of cycling performance such as speed, cadence and power are still central to the Factor001’s data acquisition. Eight tiny magnets embedded in the rims of the unique wheels log position eight times per rotation so that previously undetectable fluctuations in speed can be detected. Cadence and power are both measured with startling precision by the painstakingly CNC-machined Factor001 cranks.

By measuring the deformation of each aluminium crank arm using carefully positioned strain gauges, BERU claim to measure pedalling forces with just 0.1 percent error, while pedal position is recorded every one degree of rotation. Project leader Simon Roberts explained: “We have huge experience in this type of measurement. We saw the errors and calibration requirements of competitive power meters and knew we could do better. There's no need to calibrate our system each ride and, by measuring pedal forces very close to application, we minimise inaccuracies and gather more useful data.”

BERU designed a power meter that doesn’t need to be calibrated every ride and is accurate to 0.1 percent

Testing time

We were allowed to take the Factor001 for a test ride, and it felt direct and lively as the bolt-on rear hub and rigid rear triangle combined to ensure every watt the cranks measured made it onto the tarmac. We’d struggled to hold our line when pulling on the bars to sprint, as flexibility in the top and down tubes left the rear wheel feeling disconnected from the stiff and stable front end. The 001 is a good bike but not a great one, so once back in the factory, we were looking for a justification for the dazzling price tag.

Our questions were answered as Roberts looked at the data from our best out-of-the-saddle sprint effort, taken just minutes earlier, and was able to give startling analysis. “Each downstroke increases speed by around 2kph but once the downstroke ends your speed actually decreases by 1kph. You’re literally taking two steps forward and one back,” he said, referring to only one of many measures of our ride on display.

To demonstrate that poor pedalling technique was to blame for our stuttering progress, Roberts told us: “If you compare a graph of your power output around the pedal stroke to your speed, you can see the deceleration begins just as the useful power drops off. You’re just wasting your effort in that phase.” The precision of BERU’s analysis is humbling but for any pro hoping to beat Mark Cavendish to the line next season, the fine tuning of technique the Factor001 provides might just give them the edge they need.

BERU record the strain on the rider’s body with precision to match the mechanical measurements. A medical grade heart rate belt provides standard beats per minute data but also logs the variability in spacing between individual heart beats. Heart rate variability (HRV) is closely related to athlete fatigue. The combination of ultra-precise power data with real-time measurement of HRV means that the fatigue created by individual efforts within a workout can be measured to ensure every session is performed to perfection.

BERU are also bringing new physiological metrics into the sport. Rob Wicks, BERU F1 technician and Ironman triathlete, told us: “We use the Equivital chest strap to log each rider’s breathing rate to give a fuller picture of their effort.” Professional time trial specialists must balance optimum aerodynamics and compromised physical performance in their hunt for extra speed. “Measuring how extreme tucks affect breathing could help pros perfect their position,” Wicks suggested.

The touch screen displays and records your selection of data and can take you through an interval workout

Fitness isn’t everything in cycling as speed on a descent can win races too. Roberts and the BERU team have thrown open great new possibilities in measuring a rider’s cornering ability. The Factor001 has accelerometers housed within the head unit, while a second set is contained within the Equivital chest strap. “The chest strap and bike sensors show the lean angle of both bike and rider when cornering," said Roberts. "From that you can calculate cornering g-force so that coaches can help riders understand how to position themselves on the bike during a corner.”

The ability to optimise equipment, riding position and line choice through specific corners for maximum speed is unheard of in cycling but Roberts thinks that will change: “We've brought this technology from our motorsport work and feel sure pro cyclists will benefit." The pros may soon be experimenting with this technology but the software we saw is a long way from being consumer ready. Once it's been developed and coaches understand how best to apply it to improve cornering technique, analysing accelerometer data could become part of a team’s recce of an important time trial course or crucial descent.

The Factor001 geometry gives fast and lively handling. It does little to soften the heavier hits of rural roads though it handles high frequency buzz from pristine tarmac far better. Hydraulic disc brakes easily scrub off speed in wet or dry conditions but it’s a shame the flexible front triangle robs the rider of cornering confidence when pushing the limits of grip. We didn’t need accelerometers to feel that the 001 isn’t as fast through the bends as anyone spending £20,000 has a right to expect.

The 001 is a good bike but BERU still have work to do to make the riding experience as impressive as the data gathering ability. As we see it, the Factor001 is almost certainly not the future of bicycle training. However, the integration of BERU’s measurement technology into pro-issue bikes is almost inevitable, and we’d expect serious amateurs to pick and choose from a range of standalone sensors.

Unlocking the secrets of the peloton’s fastest descenders could help regular tarmac surfers like Fränk Schleck stay upright but it’s too early to say if amateurs will ever be able to use the same technology easily. The cost of the Factor001 is prohibitive and will only reduce if BERU can find a manufacturer willing to integrate their sensors into mass produced bikes. For now, the Factor001 is a wake-up call to cycling.

BERU have shown that inquisitive minds and the latest technology from leading industries can offer a level of scientific understanding of our sport which could push back the boundaries of rider performance even further. The cycling world now knows that engineering can translate the souplesse of a perfect pedal stroke from art into science.

Science explained – How the bike knows you’re no good

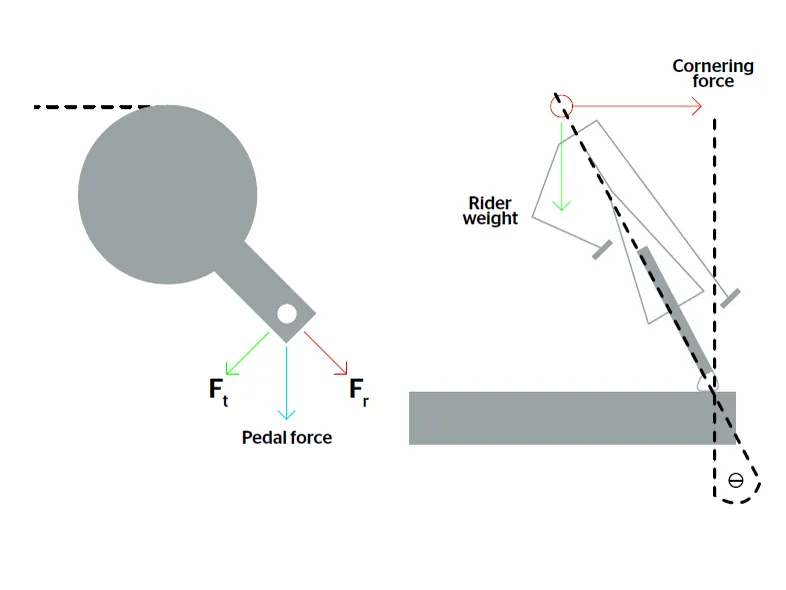

- Useful pedal force (Ft): The component of force applied to the pedal which acts to rotate crank, creating torque about the bottom bracket (BB) spindle.

- Wasted pedal force (Fr): The component of force which places the crank in tension but creates no torque about the BB spindle.

- Strain gauges: Metal foil sensors bonded to components which change resistance as the material they are attached to extends, causing them to deform.

- Accelerometers: Sensors which detect forces created by accelerations caused by changes in speed or the force of gravity. By measuring the pull of gravity acting on especially positioned arrays of sensors, the orientation of the bike or rider they are mounted to can be calculated.

- Rider lean angle: The angle between a vertical line and a line passing through the rider’s centre of gravity and the centre of the tyre contact patch. A rider leans into a bend to prevent toppling due to the cornering force.

- Cornering force: The force acting on the rider’s centre of gravity from the centre of a corner towards the outside.

Key components

- Shimano Dura-Ace Di2 battery housing: The ideal position for the battery for Shimano's electronic groupset is low and central. It’s housed in carbon fibre, of course.

- Power meter: BERU designed a power meter that doesn’t need to be calibrated every ride and is accurate to 0.1 percent.

- Head unit: The touch screen displays and records your selection of data and can take you through an interval workout.

- Hydraulic disc brakes: BERU built hydraulic master cylinders into Shimano Di2 levers. Disc brakes freed up the wheel design.

Q&A with Factor001 project leader Simon Roberts

What brought BERU into the bicycle industry?

BERU F1 boss John Bailey asked us to design a vehicle without an engine from the ground up, to showcase our instrumentation and composites capabilities. The Factor001 bike was a natural choice for a vehicle without an engine and having designed such a cutting edge product it has led to BERU being accepted and respected by the cycling world.

How has Factor001 been received by pro teams and manufacturers?

I took the Factor for an ‘undercover’ walk around the pits at the Tour of Britain just to show it off a bit and the response was fantastic. Directors from big-name teams and some very large manufacturers showed real interest in the bike and how they could bring our technology into their design process and products. Handing them a business card and telling them I’d designed the Factor001 was a major satisfaction.

Where do you see the Factor001 fitting into the road bike market?

Although the Factor001 will undoubtedly be bought as a status-bike by some riders, I wouldn’t see us becoming a big manufacturer of complete bikes. The Factor001 is more about showing other people how we can help them make better bikes or introduce novel features into their existing product.

Which aspects of the Factor001 are you most proud of?

Personally, the S-Drive fasteners we designed epitomise the no compromise approach our team of engineers took on this project. We needed lighter, stronger fasteners than anything currently available, so we designed them.

Was there a technology that you weren’t able to incorporate into the 001?

We looked long and hard at physiological metrics and the only useful one we wanted that wasn’t possible to provide was breath gas analysis. We were told people wanted to see real-time oxygen consumption figures but that was a step too far even for us. We're proud to offer riders core-temperature sensing from an encapsulated sensor which is swallowed by the rider and then transmits data to the head unit. Performance in the heat has received a lot of attention from pro teams so we think that's a great addition.

What is the future of the Factor001 project?

The first task is to put our cranks into production. We feel they have the greatest value to serious amateur riders. We're also helping people develop software solutions to process the accelerometer data. The industry will catch up but BERU isn’t a software company so we’ll just have to wait.

Rob Wicks (left) and Simon Roberts with their creation. Having started as a showcase, their work has a real future in the sport