Excluding your mind, hands and perhaps bottle opener, nothing in the bicycle workshop is likely to get more use than Allen keys (AKA hex keys, Hex wrenches). So why is that so many of us will invest in other bicycle-specific tools, but make do with cheap L-shaped Allen keys or worse, a multi-tool?

Taking a peek in a well equipped workshop or pro-mechanics tool box will reveal that the experts don’t often agree on what type of hex wrench is best — and, more importantly, they rarely make-do with just a single style. On top of this, you’ll just about always find a torque wrench or two.

- The right tools for the job: building and affordable home workshop

- 5 ways to make your old bike feel like new

Where most Allen keys will get the job done, the right tool for the job will be one that's more efficient and will potentially give you better results.

Sure, a debate about different types of Allen key is trivial at best and perhaps comparable to bicycle saddles — what works for one person doesn’t mean it’s right for you. But how does less time fixing and more time riding sound? Good, right?

Below I explain the different styles of Allen key and when to use them. If you’re a home mechanic and have never put much thought into these tools, read on (also keep reading if you buy lots of Ikea furniture). This article applies equally to Torx wrenches too, because the star-shaped tool is quickly becoming commonplace on high-end bicycles.

Allen/hex keys for cyclists

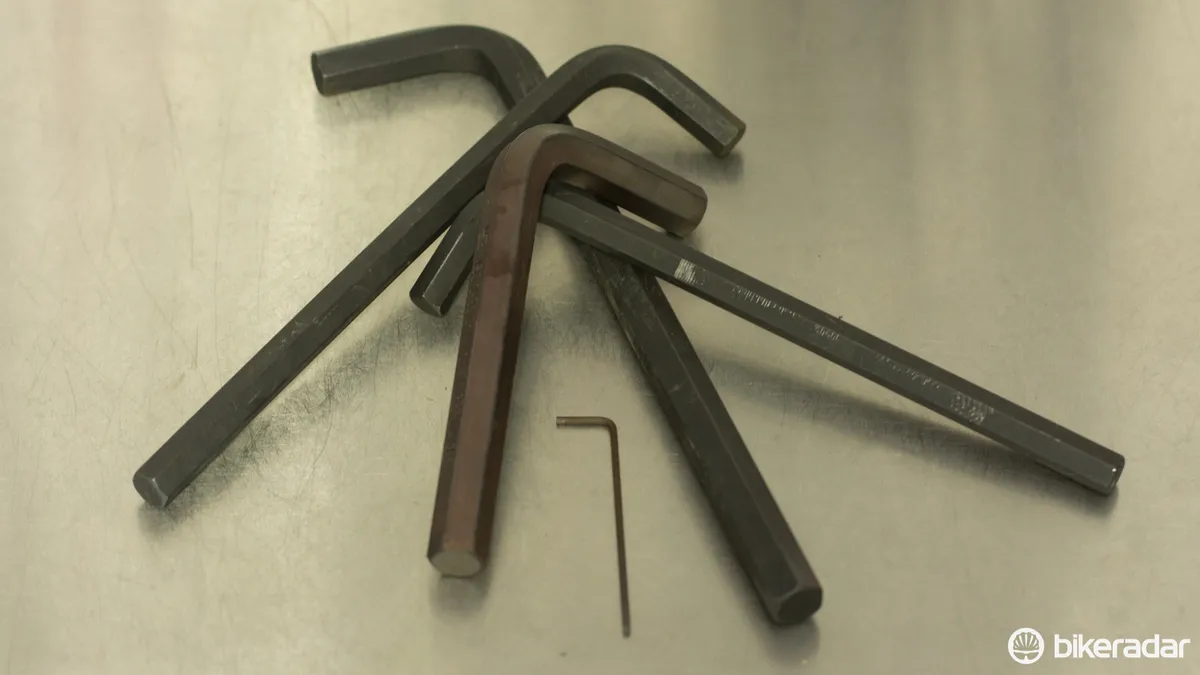

L-shaped

The old faithful. This is the standard Allen key and is easily and cheaply sourced wherever you are. The L-shape offers versatile reach into tight spots while also allowing leverage when needed.

If you could only have one set, this style would be it. However, it lacks the weight to easily spin the wrench for fast threading and it can be uncomfortable in the hand for long periods of time.

With hundreds of choices available, a 1.5–10mm set of long Bondhus wrenches will always prove a good value purchase.

T-handle

Popular in motorsport applications, the T-handle acts as a balanced weight to help you spin the wrench quickly, while allowing enough leverage for common usage. Some areas of the bike won’t suit a T-handle (such as adjusting most seatposts) while cranks and pedals will often be too tight for common T-handles.

Beta 951 wrenches, which allow the T-handle to slide into a position to create an L-style tool, are an exception. These are quickly becoming the choice of many professional road and mountain bike mechanics (and of this contributor!), but at over $20 per wrench, they're items best suited to those who get a financial return on their tools.

P-handle

This type of Allen key, made popular by Pedros, Park Tool and others, is something I see lots of in professional workshops. It's effectively an oversized L-wrench with a comfortable grip at the bend that gives it similar benefits to a T-handle.

I’ve used these for many of my wrenching years — they're a solid choice and only rare instances, such as seat clamps, will call for a different style.

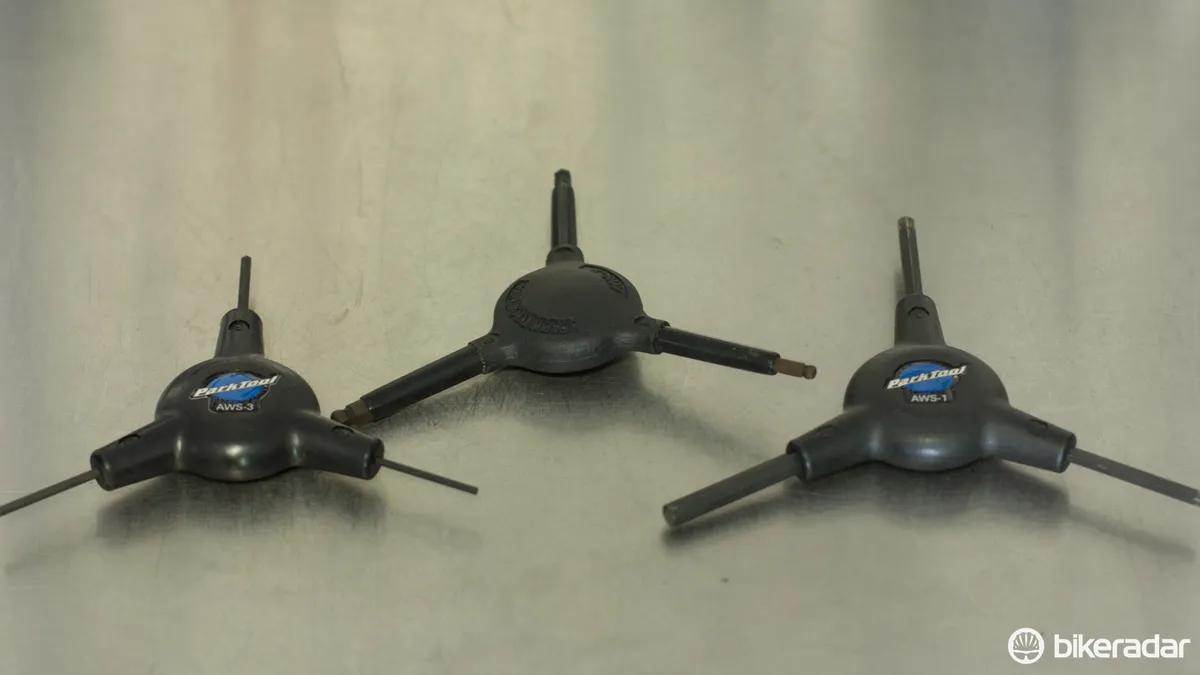

Three-way

Park Tool made this style, which places three of the most common sizes into one tool, famous… and mechanics around the world still naturally reach for it. Many brands now offer two or three different sizes of three-way, but the standard 4, 5 and 6mm three-way remains the gold standard. Much of a bike can be built with this one single tool.

Sadly, however, the limited length and triangular shape means it’s a poor choice when working with tight clearance. Installing bottle cages, adjusting a saddle or even just adjusting a disc brake caliper will prove slow, if not impossible.

Folding

Effectively what multi-tools are based on, you can get a full set of Allen keys as a folding set with the storage doubling as the handle. This ‘Swiss-Army knife’ of bicycle wrenching is popular with some mechanics, as they rarely need to reach for other tools.

Of course there are many downsides including a general lack of leverage and clearance. Out of all the styles mentioned, this is the only one I don’t use in the workshop, but I do keep one in the car.

Ratchet

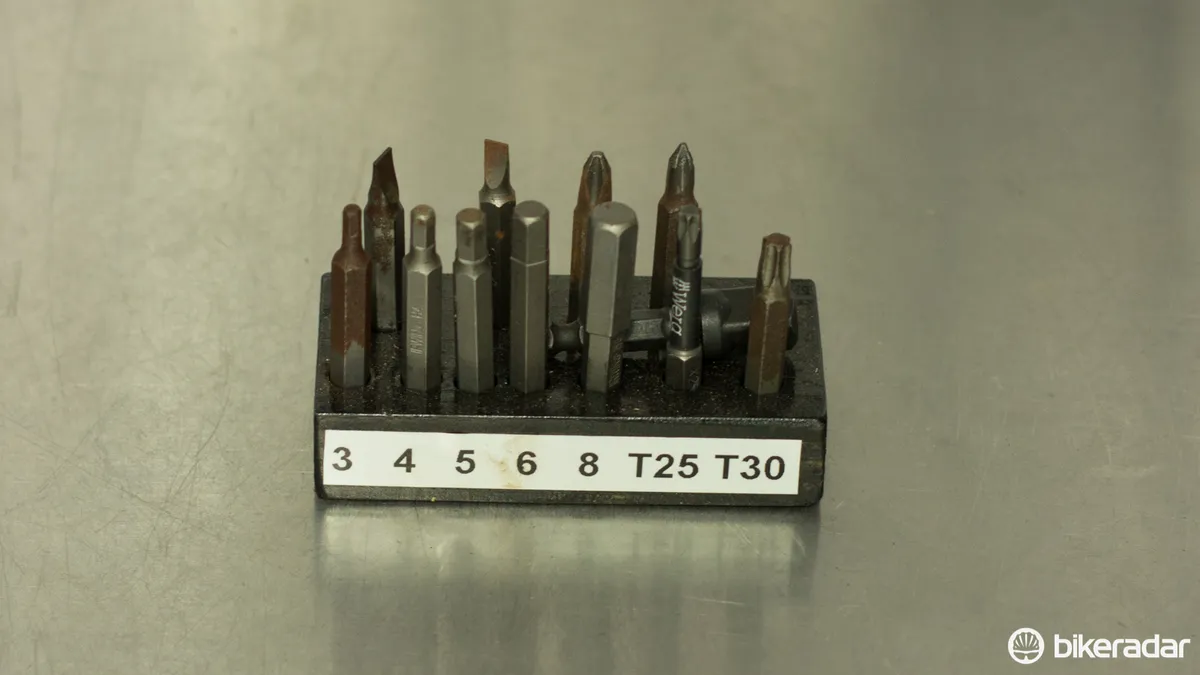

Ratchet Allen keys are available in a few different varieties. The best ones for bicycles use replaceable bits instead of actual sockets, keeping the tools' profile shallow. A ratchet offers significant speed benefits, but will require swapping between different-sized bits.

While it’s possible to do most of the bike efficiently with a ratchet, I keep a PrestaCycle ratchet handy only for fiddly items such as saddle clamps.

Additionally, the bits of these ratchets can be used in an electric drill driver. This is certainly something that can do more harm than good when used incorrectly, but it's a popular choice when working with rotor bolts (commonly a T25 bit) and other repetitive tasks.

Screwdriver-style

Far from a necessity, the screwdriver type is handy for when low torque and tight clearance are key factors. This style is my go-to for bottle cages and adjusting lever reach on some disc brake levers — otherwise they don’t see much use. The Bondhus 1.5–5mm set is what I use.

Torque wrench

The Torque wrench is an important part of the workshop, especially if you’re working with any delicate components, but it isn’t a replacement for the hex wrench, especially when undoing bolts. (In fact, torque wrenches really deserve an entirely different article — and fortunately we have a complete guide here.)

Don’t buy cheap

Go to a local hardware store and you’ll find a plethora of options, including those starting at pennies. While you may get truly lucky and find a decent set on the cheap, you generally do get what you pay for when it comes to tools.

Cheaper tools lack the durability of more expensive counterparts, but more importantly they generally lack the tolerances and much-needed tight fit with a bolt head.

The torque applications on bicycles are generally pretty low but often so are the tolerances. If you’re using a sloppy tool, chances are you’re going to strip (cam out) a bolt.

It’s certainly not an enjoyable experience and in some cases can be an expensive mistake. In most instances a decent set of Allen keys will be far cheaper than replacing that proprietary pivot bolt holding in your rear shock you just stripped.

Since originally publishing this article, I wrote in detail on why you should avoid buying cheap cycling tools. The snippet below displays a wide range of 5mm Allen keys measured with a micrometer. It proves how much tolerances can vary between brands.

For a 5mm Allen key, you want it as close to 5mm as possible as the bolts are oversized to fit this. As you can see, the cheaper Chinese options are the clear losers — while the US made and European tools are often superior.

Sample 1

Sample 2

Sample 3

Mean average

Bondhus Standard

5.014

5.002

5.007

5.008

Bondhus ProGuard

5.007

5.007

Bondhus ProGold

4.998

5.002

5.000

Park Tool (Bondhus)

5.004

4.994

4.983

4.994

Crank Brothers Multi 17

4.993

4.993

Wiha

4.988

4.988

Jet Black multi-tool

4.987

4.987

Beta

4.982

4.991

4.987

Kincrome (Taiwan)

4.986

4.986

Pedros

4.958

5.013

4.986

Irwin Impact Bit

4.985

4.985

4.985

Topeak Mini 9

4.983

4.983

PB Swiss

4.98

4.980

Mac

4.987

4.967

4.977

Unior

4.992

4.965

4.964

4.974

Wera

4.97

4.970

PrestaCycle Bit

4.965

4.975

4.970

PRO multi tool

4.968

4.968

Generic Chinese

4.963

4.964

4.974

4.967

Birzman

4.928

4.964

4.946

Lezyne Stainless Multi

4.94

4.940

Arraytable { }td { padding-top: 1px; padding-right: 1px; padding-left: 1px; color: black; font-size: 12pt; font-weight: 400; font-style: normal; text-decoration: none; font-family: Calibri,sans-serif; vertical-align: bottom; border: medium none; white-space: nowrap; }.xl63 { }.xl64 { font-weight: 700; }

This .06mm is just a hair's difference, but use each of the two extreme examples in the same bolt and you’ll feel an obvious change in grip and movement, and likely see the undersized version cut into the edges of the bolt before it begins to turn.

Tools wear

With much of the force happening on just six edges at a shallow depth, it's not hard to cause wear.

If you’re getting regular use out of your Allen keys, pay close attention to the conditions of the tips. You want sharp edges — rounded or burred edges are a sign that the tool isn’t as good as it can be and you’re at risk of rounding out a delicate bolt.

Ball drivers

Ball drivers are a common feature on L and P-style tools and allow for angled access to a bolt.

The downside to a ball end is less surface area with the bolt, which means they are more likely to strip under high torque. Ball drivers are great for nipping things and spinning things off, but use the square end of the wrench for initial loosening or final tightening.

Length and leverage

For some applications, such as undoing tight pedals or crank arms, leverage will be a key factor. Looking at a set of Allen keys, you’ll note that the larger the size, the longer the tool — this is simply because larger bolts can cope with greater torque.

If you only own a set of short Allen keys, consider getting at least the 8 and 10mm sizes in a longer length.

Remember to be wary of the leverage when tightening a bolt. The torque outcome is very different depending on where along the tool your hand is placed. It’s highly unlikely you’ll need the full leverage available on that long 5mm key.

Another factor is the length before the handle or bend, and some deeply in-set bolts may prove difficult to reach with regular Allen keys. An example of this is Campagnolo Ultra-torque cranks, which require a long 10mm bit to reach the middle of the hollow crankset spindle.

Ultimately, the best tool is one you're most used to using and can trust. If you’re an occasional mechanic, a quality set of L-shaped keys will serve you well. But if serious about doing your own work, consider ways to improve your efficiency — every type of Allen key has real benefits in the right circumstances.

Updated November 2017