Having previously discussed how to build a cycling tool kit from scratch. Now, we’ll look at the larger, more general items and equipment that any well-stocked home workshop should have.

Not everything in this roughly-ordered selection will be necessary for all home mechanics. What you need depends on how much DIY you intend to be doing. There may also be some cycling-specific tools that you should invest in before buying some of the items here.

- Handy essentials for the home workshop

- The right tools for the job: building an affordable home workshop

The first thing you need is a well-lit, ventilated space with access to a power supply — that's a must for any home workshop. Consider the space you have available and prioritise the most important things, tool storage, for example.

Workstand

Beyond basic tools and a track pump, a workstand (or repair stand) is the greatest addition you can make to your bike servicing set up. It enables you to focus on the task at hand without worrying about the bike toppling over.

Sure, you can flip the bike upside-down to spin the wheel and adjust the brakes and gears, but that just won't suffice for many repairs.

For most home mechanics, a tube clamp stand is the way to go. This sort of workstand allows you to fix bikes with both wheels in place. For this, the Park Tool Home Mechanic PSC-10 is the stand to beat. It can be found reasonably cheaply, its clamp fits nearly every bike, it can be folded down and it’s built to last.

If you have a little more to spend and want a stand that’s easier to fold and carry (to races, for example), the Feedback Sports Pro-Elite is my pick.

Workbench

A workbench should be solid enough for you to smack stuff on it, spill oil on it, support your weight and withstand years of abuse. So despite what it might say on the box, simple snap-together plywood shelving units do not make a good workbench.

Ideally, you want a bench that’s at least a 120cm (47in) wide and 60cm (23.6in) deep — this will give you enough space to lay most of a wheel on the bench, work on other large items and still have a vice mounted to it. That said, more bench space is always better, so if you have room for a bigger bench, get one!

Big hardware stores offer pre-built options for workbenches, but a cheaper option is to build your own from wood, or metal if you’re really handy. There are plenty of sites that will provide inspiration for this, such as garagejournal.com.

Repurposing kitchen bench tops and cabinets is another way to find a bargain. I use a steel bench from Ikea that I've modified slightly and reinforced over the years – it’s not perfect, nor the cheapest, but it serves its purpose.

The space under the worktop should serve as storage. Drawers are perfect for keeping small parts in check, but cabinets provide space to keep solvents, cleaners and other bottles.

Solvents, oils and other muck will quickly seep into cheaper unfinished wood surfaces. We recommend building the work surface from something like marine ply, or covering it in stainless steel — both are expensive, but easy to clean and will keep for a long time.

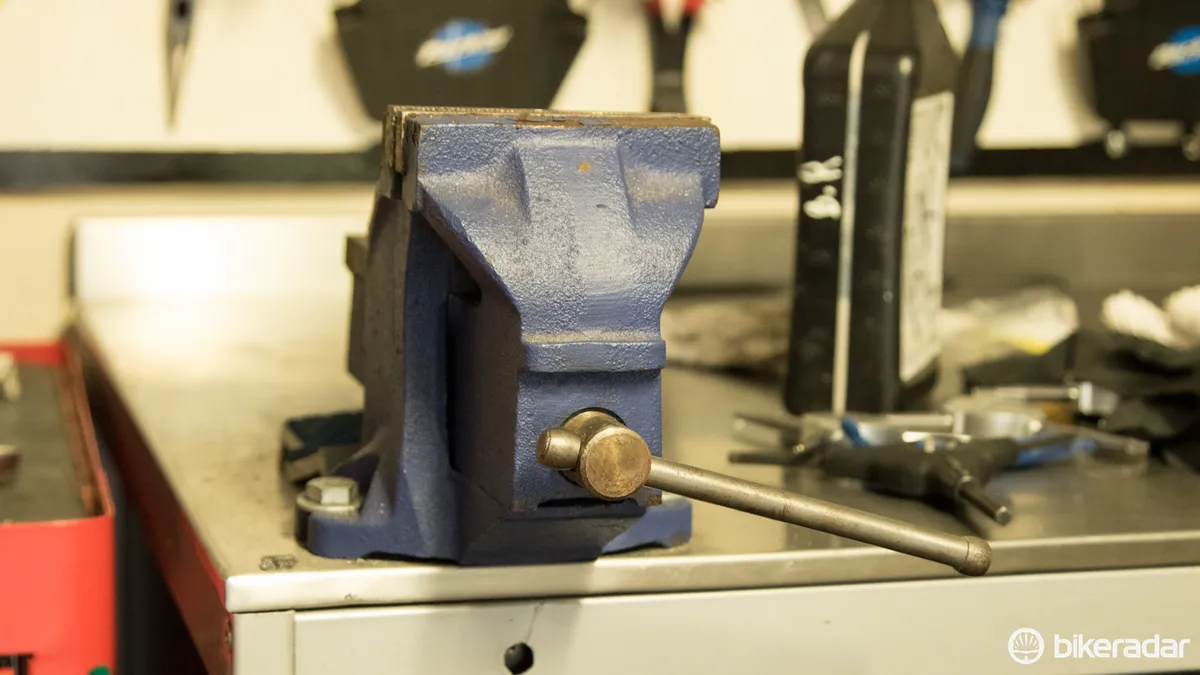

Bench vice

A decent vice bolted to that sturdy workbench will regularly prove useful and should last a lifetime. Fixing bikes rarely calls for an industrial vice and so a reasonable quality 100 or 125mm width vice will do the job.

An Irwin Record is a proven and good value option that’s quite widely available.

Once you’ve got the vice, get yourself a simple set of axle jaws, the ones from Park Tool are good. These will let you safety hold pedal and wheel axles without damaging the threads.

Wheel truing stand

Basic wheel truing can be achieved with the wheel in the bike, using a zip tie or similar as a gauge, but for more involved and accurate repairs you can’t beat a truing stand. Truing, or even building, wheels requires a fairly high skill level, so a truing stand is something that only a more dedicated home mechanic needs.

When buying a truing stand, be aware of your needs and bike type. There’s no point getting a cheap road wheel stand if you need to true 29in mountain bike wheels with thru-axles. The Feedback Sports single-sided stand is good for working with basic quick-release axles; it’s compact, accurate and will last, but thru-axles users will need to buy special adapters.

Park Tool’s TS-2.2P is based on a true classic that the majority of shops use — it’s the same stand, just powder-coated instead of chromed. If you’re serious about tweaking those nipples, this stand is a good buy. It will last a lifetime too.

I personally own a DT Swiss Proline truing stand, and while I love it, given its price, I would recommend the Park stand.

Electric drill

An electric drill is great for drilling holes, but many shop mechanics will also use a drill to install and remove disc brake rotor bolts that are covered in Loctite, and make for tedious work with hand tools.

You don’t need the power of an industrial model, a basic cordless drill is adequate. A tool-free chuck and adjustable clutch are both useful features.

For disc brake rotor bolts, I personally use a Milwaukee adjustable-torque driver. This works slightly differently to a drill (it’s an impact driver), but a drill is a far more useful purchase.

Parts washer

Once you’ve got the tools to remove a cassette and cranks, you may as well have a place to clean them. For most, an ice-cream container, a brush and some simple-green will do the job just fine, but if you want a more permanent solution, consider a basic bench-top or freestanding parts washer.

These can be bought easily, with the major cost being the solvents to fill them. It’s extremely handy having a space that's always ready for a quick degrease when you're replacing a chain or doing that monthly spruce-up.

Air compressor

An air compressor is not a replacement for a quality track pump, but it is still a great addition to a mountain biker's home workshop. It's handy for seating tubeless tyres and cleaning out muck.

A small, basic air compressor can be bought quite cheaply from a hardware store, cheaper than a good track pump in many cases! In addition to a cheap blowgun, you'll need a tyre inflator, something that's available from the likes of Prestacycle and Park Tool – or you can make one from an old floor pump hose/head and an inflator from a hardware or automotive store.

Be aware that this addition to your workshop will likely bother your neighbours, so it's certainly not one for dense living environments unless you get a more expensive silenced model.

Dremel

They're not quite so popular now that the oscillating multi-tool has become the DIY home renovation go-to, but a high-speed rotary tool can still come in handy.

Dremel is no doubt the key brand for these tools. It offers a wide range of bits for fine sanding, polishing, grinding, drilling, cutting, engraving and plenty more. I used to get plenty of use out of mine in my weight weenie years, but now it’s mostly used for fixing burred chainrings and seized components.

Bench grinder

I’m only including a bench grinder on this list for those home mechanics who use it all the time and will complain if I leave it out! I have one, and use it, but not often. It’s useful for sharpening tools and doing quick grinds on freshly cut steerer tubes.

Shop stool

Your mates will need a place to sit while they watch you dial in their bikes. And you'll need it when you've finished fixing your bike so you can sit back and sip that beer while you marvel at your handiwork.