Before suspension, which didn’t become mainstream until as recently as the late Nineties, mountain bikes were proper bone-shakers. On those old rigid-forked, rigid-framed bikes rough sections of track were exhilarating rollercoasters, but had you grimacing and your eyeballs rattling in their sockets.

When suspension was first introduced many riders turned up their noses at the ugly, heavy, flexy and very inefficient early designs. Nowadays it’s a different story; modern suspension bikes allow you to ride faster over uneven surfaces, further and for longer as they reduce impact and strain on your body. They smooth out ugly landings and save your bacon when you get out of your depth.

Suspension has two jobs on a bike: to keep the wheels in contact with the ground as much as possible to improve traction, and to cushion the impacts a bike deals with on rough terrain. If it’s not set up correctly, even a great suspension bike can feel like riding a mattress and really hold you back. Once you get your fork and/or shock dialled in, however, your riding will take a leap forward.

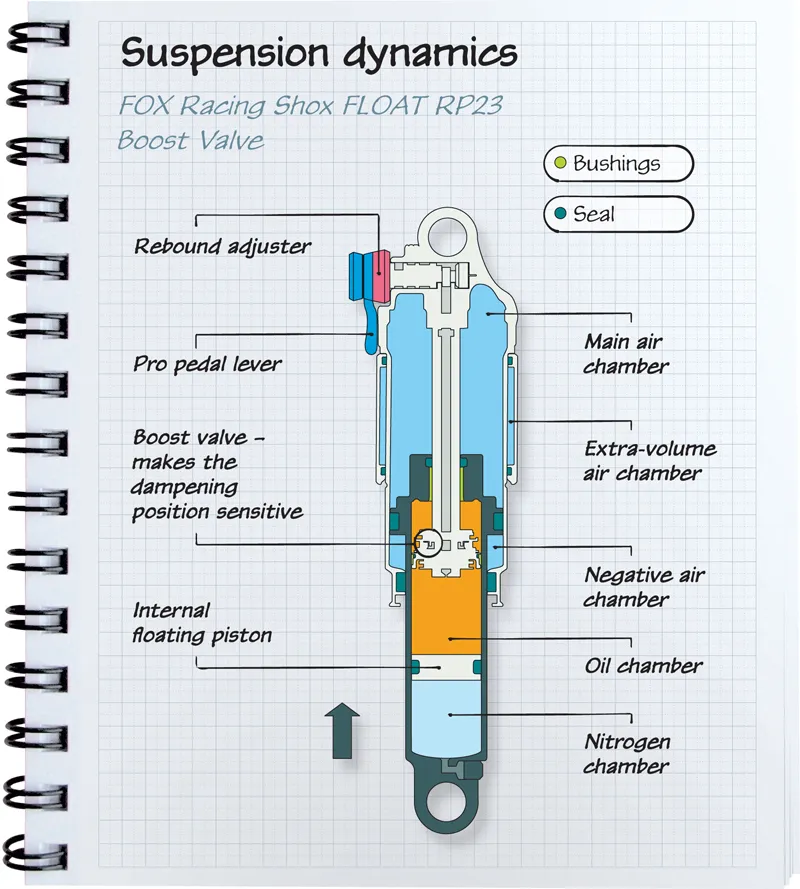

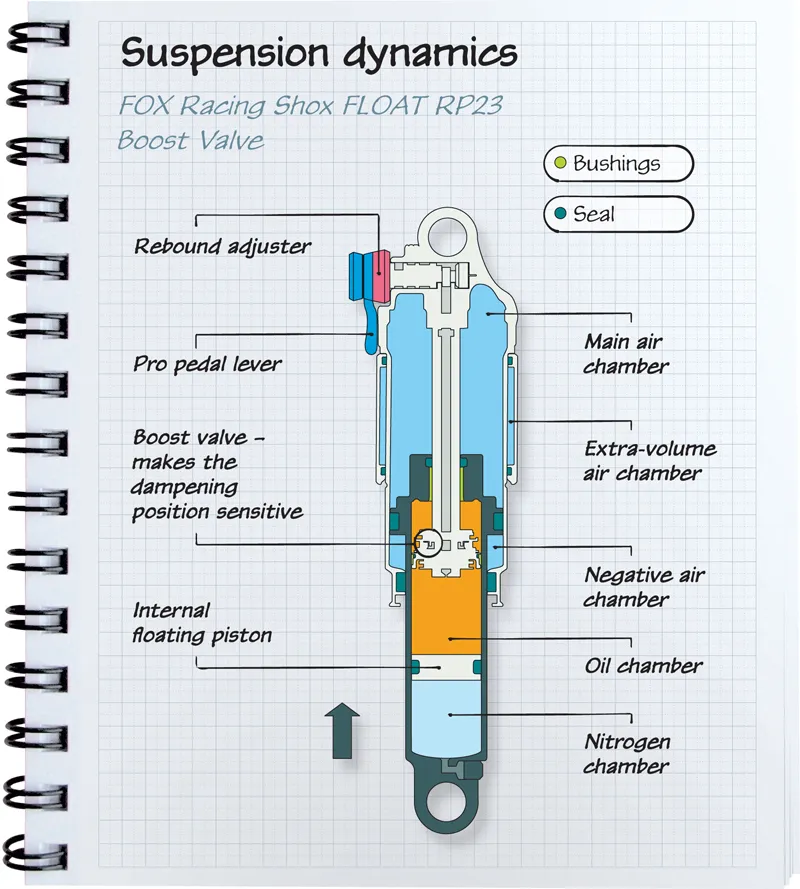

Suspension comes mainly in two forms: coil sprung or air sprung, although elastomers still get a look-in on low-cost forks. All suspension features compression and rebound damping to adjust the rate at which the fork or shock dives through its travel and returns. Cheaper shocks and forks may lack external adjustments, but it’s commonplace now for suspension to have at least external rebound controls.

Well set up suspension enables the wheels to follow the contours of the terrain by letting them drop into hollows and move around rocks and lumps. To do this, suspension is set up with sag – meaning your weight on the bike allows the bike to sit at a set point within the travel. Sag is usually set between a quarter and a third of the available travel.

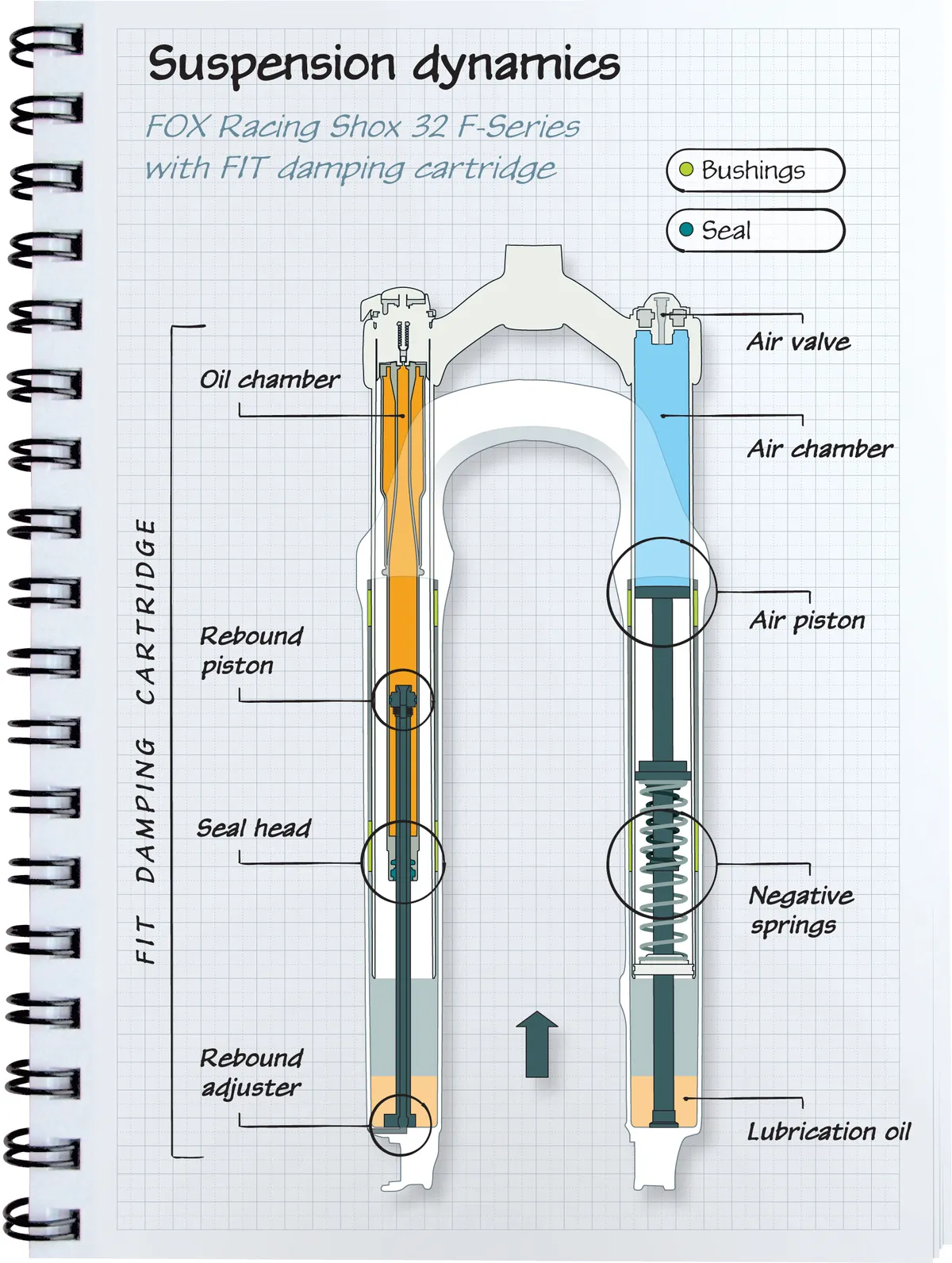

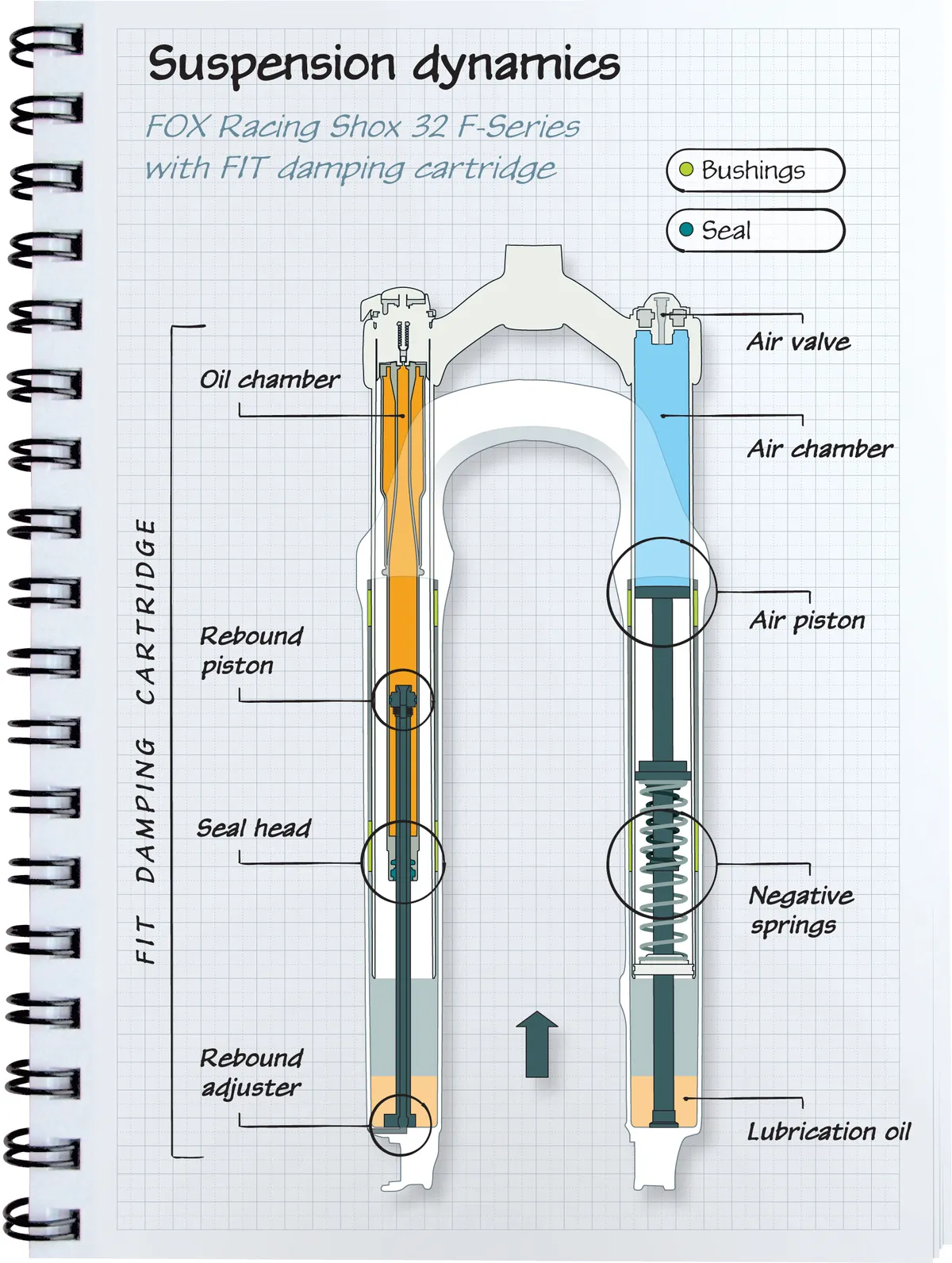

Almost all forks and shocks share the same basic construction: a tube that slides inside a larger tube, with the spring and damping system contained within. Most forks are telescopic, and consist of two upper legs (stanchions) – joined by a crown – which slide in and out of a one-piece lower leg construction (sliders).

Rear shocks are a scaled down version, albeit with one leg, and in the case of coil shocks with the coil spring on the outside rather than inside (coil-over shock). As the fork or shock is compressed it squeezes the spring medium, which stores the energy then releases it as the fork/shock rebounds. Damping dissipates this energy and is used to finely control how the suspension behaves during compression and extension.

Chassis

Forks and shocks are available in many shapes and sizes to suit the intended application, from cross-country racing to dirt jumping, and the rider. There are a number of standards to be aware of though, many of which may or may not be compatible with your setup.

Rear shocks are somewhat easier to get right – the frame has precise measurements that must be matched, such as shock eye-to-eye length, shock stroke and specific fitting hardware. Forks, however, have all sorts of differences. Modern fork steerer tubes come in three diameters: 1 1/8in (equals 1.125in), 1.5in and tapered from the latter measurement to the former (all beefier than the old 1in standard).

Which will fit your frame depends on the size of your head tube and headset. Tapered steerers are a recent development that combine the stiffness of the 1.5in width at the crown with compatibility with standard 1 1/8in stems, with hardly any weight penalty. They require a tapered head tube or special headset to fit.

As with forks, there are also a number of different types of axles. Most forks have 9mm quick-release (QR) dropouts, a carry-over from road bike technology. But in order to reduce flex, screw-through (also called through-axle) forks are becoming increasingly common. Like steerers, these require specific hardware, in this case a compatible hub.

The two main standards for screw/bolt-through axles are 20mm and 15mm, and hubs are available that can be converted between the two, and even from quick-release. Alongside the new axle standards, thicker, wider stanchions also increase fork stiffness and allow more precise steering, less twisting and reduced braking flutter, but the penalty for all this is increased weight.

Travel

Fork or shock travel – the total available compression – is typically between 80mm and 200mm (3-8in). More travel allows a softer spring rate and gives the fork/shock more time to deal with an impact, increasing the control over energy absorption. The amount you need depends on the intended use and what your bike is designed to handle, given its geometry. Check with the manufacturer before fitting new suspension so as not to invalidate your warranty or affect your bike’s handling adversely.

Springs

The spring stores the energy created when the shock or fork compresses. In cross-country forks it's usually compressed air or it may be a metal coil. Air springs can be precisely adjusted to the rider’s weight and are lightweight, but air sprung forks can suffer from stiction (when the stanchions don’t slide smoothly in the lower legs because of flex in the fork) and resistance from increased sealing.

Unlike a coil, the spring rate increases as the fork compresses, known as progressive suspension, which can lead to the unit ramping up (becoming stiffer) at the end of the travel. Coil springs have an adjustable preload to set the ride height and sag, but the adjustment window is usually very narrow and often a change of spring is needed to get the desired results.

Damping

An undamped fork or shock would simply take the energy stored in the spring and fire it right back at you. Control is important, and that is achieved by forcing oil through ports and shims inside the stanchions to slow the action down.

Rebound damping is exactly that: as the fork or shock extends from a compression, it slows the rebound and turns the excess energy into heat as the oil is squeezed through the valves. Most forks and shocks will have an adjuster to precisely tune how fast you want them to rebound. Too much damping and the fork/shock will pack down (ie have less travel) over successive hits, too little and it will feel uncontrolled and bouncy.

Compression damping controls the fork/shock as it compresses, allowing it to react proportionately to different sized impacts. Slow-speed damping regulates movement such as brake dive, fork bob and excess compression in berms, while high-speed damping can prevent the fork/shock blowing through the travel (bottoming out) on big hits and drops.

Too much high-speed damping can be a bad thing, though – the oil pressure may build up causing a spike (when the oil can’t get through the ports or shims fast enough), which can be felt as a sharp knock. Sophisticated forks and shocks have shim stacks – thin washers that can bend out of the way – allowing the oil through and the fork/shock to move faster.

Lockout levers prevent the fork or shock moving, sometimes completely but many retain a little bit of travel to help traction. Lockout is useful on smooth climbs or road sections. Blow-off adjusters let you set the force of impact that will knock the lockout off to regain full travel. Not all forks and shocks have all these features, but the very least you need is rebound damping.

Jargon buster

Suspension fork terminology

- Adjustment dial(s): Also called top caps. Besides allowing external adjustments – including compression, rebound, threshold and travel adjustment among others – the top caps seal the top of the stanchions/air springs.

- Air valves: Depending on the fork, these can be for the main or supplementary air springs, the negative air spring or platform damping adjustment valve. Keep clean and check the valve core is tight if you get a leak.

- Axle: This can be a regular 9mm quick-release, 20mm bolt-through or 15mm bolt-through. Now quick-release bolt-through axles, such as RockShox’s Maxle and Maxle Lite (20mm and 15mm for 2011 forks) and Fox’s QR15 (15mm), are increasingly being seen on cross-country and trail bikes.

- Bushings: Synthetic slider guides for smooth telescopic action between upper and lower legs.

- Crown: The 'hips' that hold the fork stanchions and attach to the steerer tube.

- Dropouts: Traditionally forks used slotted 9mm dropouts for quick-release hubs, but with the new 15/20mm through-axle standards compatible forks have a hole rather than slot to slide the axle into.

- Fixing bolts: Extremely important fork end bolts that hold the internal spring/piston rods in place, stop damping oil leaking out, and the whole lower leg assembly falling off.

- Fork brace: An arch (or sometimes a pair on brands like Magura or DT Swiss) that stops the lower legs moving independently by preventing torsional flex to ensure good tracking.

- Lockout lever: Stifles oil and air flow through the compression or rebound circuits to lock a fork rigid – handy for climbing or spinning on the flat. Most have a blow- off (sometimes adjustable) valve to stop unexpected hits snapping your wrists.

- Negative spring: Helper spring that opposes the main spring to help overcome seal resistance.

- Preload adjuster: Increases the initial spring resistance of coil and elastomer forks. If you’re using more than several turns, consider the next spring weight up.

- Rebound dial: External adjuster for the rebound damping circuit. May be on the top of the fork leg or at the base and is normally red in colour. Increasing rebound damping slows down the speed at which the fork leg returns after each hit; decreasing rebound damping speeds it up.

- Remote levers: Fly-by-wire bar operation of one or more of the fork leg/ crown mounted adjusters.

- Seals: Multiple wipers and lubricating sponges vital for keeping insides in and dirt out. Clean and check for damage often.

- Slider/lowers: The moving part of the fork made of cast magnesium or carbon fibre. Big generally means stiff (on freeride/aggressive trail forks), skinnier generally means lighter/more flexible (cross-country forks).

- Spring: Provides the basic up and down motion in air (light and easily adjustable), coil (ultra smooth and reliable), elastomer (cheap) or a mix of all three. Can be in one leg or both.

- Stanchion: Slippery upper leg so the lower leg can slide smoothly over it. Occasionally steel, mostly aluminium and ranging from 28-40mm diameter, increasing in stiffness and strength as width increases. Watch for scratching or corrosion as this will rapidly ruin seals.

- Steerer tube: Aluminium or carbon to save weight, or steel to boost strength and reduce cost. Come in a variety of sizes, with 1-1/8in being the cross-country standard and 1.5in steerers standard for freeride or downhill bikes. Tapered steerers (which taper from 1-1/8in at the top to 1.5in at the fork crown) are common on all-mountain or aggressive trail bikes where both stiffness and light weight are important.

- Travel adjuster: Various travel adjustment systems are used by different manufacturers to let you change the amount of travel either on the go or when stationary. This can be useful for effecting geometry changes for climbing or descending. The adjustment can be stepped (such as 100-150mm), incremental (3mm per click) or infinite (free adjustment anywhere within the range of travel) depending on the system, while other forks can be adjusted internally (such as to reduce a 120mm fork to 100mm travel only).

Rear shock terminology

- Air valve: Schrader valve used for adding or removing air from the positive air spring on air shocks. Normally marked with a ‘+’ on it. Keep clean and check valve core is tight if shock starts to leak.

- Bottom-out bumper: Simple bumper to stop a harsh clang at full compression.

- Coil: Metal coil spring on coil shocks. Can be steel or titanium (for light weight), straight rate or rising/ falling rate. Spring weight (in ft/lb) will normally be printed on the side as well as the dimensions.

- Compression adjuster: Dial or lockout lever that controls the compression damping circuit.

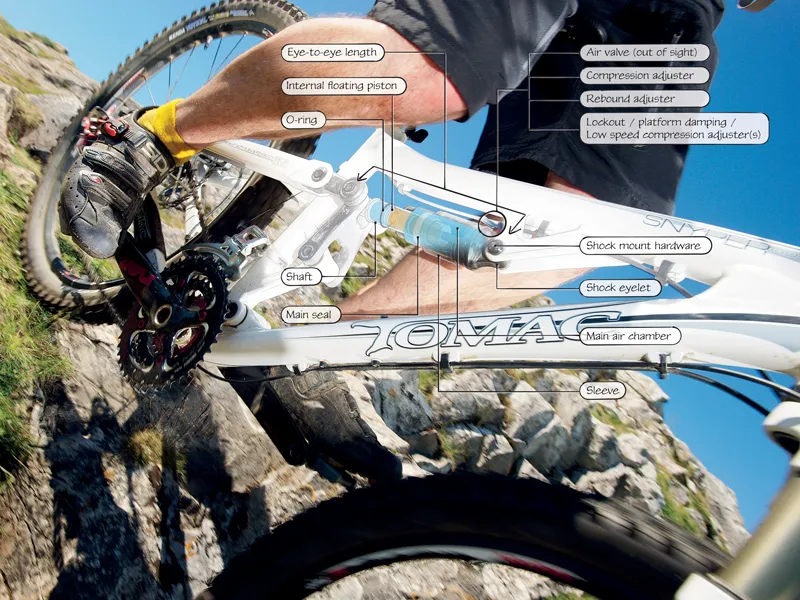

- Eyelet: 6mm or 8mm hole at either end of the shock.

- Length: Shocks come in various lengths. It’s measured from eyelet to eyelet (eye to eye length).

- Lockout / low-speed compression: A damping circuit that resists compression from low-speed inputs like pedalling forces.

- O-ring: Rubber ring on shaft showing the ‘tidemark’. Helps accurate sag set-up by showing how much travel is being used when sitting on the bike.

- Piggyback chamber: Extra damping or air spring expansion chamber mounted parallel to the main body. Used mostly on all-mountain and downhill long-travel air shocks.

- Preload collar: Only on coil shocks. Threaded collar that can be used to add additional load to the spring for a stiffer start. If you’re using more than 2.5 turns from contact we’d advise you get the next spring up.

- Rebound adjuster: Controls the rate at which the shock extends after compression. Normally coloured red but can sometimes be blue. Check your manual.

- Seal head: Wiper seals designed to keep the insides in and the outsides out. Check for any splits, embedded grit or other damage before it scars the shaft, and clean regularly if the shock can be dismantled (most air shocks can).

- Shaft: The moving part of the fork made of cast magnesium or carbon fibre. Big generally means stiff (freeride/aggressive trail), skinnier generally means lighter/more flexible (cross-country).

- Shock mount: Normally just a sandwich of alloy spacers but can be a spherical rose joint to reduce sideways stress. Check width is correct for your bike, check for wear/rattle regularly and replace immediately if this occurs.

- Sleeve: Air-tight can that contains compressed air acting as a spring. Some are adjustable to change travel or internal chamber dimensions, and therefore the shock rate.