In any evaluation of bicycle brakes — road, mountain, mechanical, hydraulic, rim, or disc — the subjects of power and modulation are bound to come up. The former is an easy and intuitive concept to grasp but what about the latter? What exactly is brake modulation, anyway, and why should you care about it?

Power vs. control

Braking power is always limited by tire traction and virtually any brake can lock up a wheel. However, a wheel that isn't rotating is also usually a wheel that isn't contributing any meaningful amount of control. Aside from certain situations, lockup is exactly what you don't want.

From a performance standpoint, better brake modulation means you can actually go faster, confident in your ability to reduce your speed at precisely the last moment

Let me repeat: lockup is usually not a good thing and anyone who argues that their current brakes "can lock up a wheel just fine" is tacitly admitting that they don't work as well as they could.

Brake modulation is the ability to precisely and accurately control the amount of clamp force on a rotor (or rim, which in some ways is just a big rotor, anyway) with a given amount of lever input.

In other words, it means you can scrub off as much or as little speed as you want without breaking traction — unless, of course, that's what you're trying to do.

Peak braking power comes just prior to lockup and it's the ability to flirt with that limit that makes modulation so important. Whereas a lesser brake might unpredictably vacillate between moderate braking force and lockup — thus, skipping that all-critical peak in deceleration — a brake with excellent modulation will allow you to consistently peg that mark over and over again.

"A brake that has good modulation in our view would be one that you could take right to the edge of locking up and then control it there as you need it to," said Avid product manager Paul Kantor, "or scrub off a little bit of speed without having it ramp up so that it suddenly spikes on you."

From a safety standpoint, such control will produce shorter stopping distances. But from a performance standpoint, better brake modulation means you can actually go faster, confident in your ability to reduce your speed at precisely the last moment so as to waste as little time as possible.

Input vs. output

Often you'll hear people mutter the phrase, "brake modulation should be in your fingers, not in your brakes." That's absolutely true in some sense but there are still characteristics that can be built into a brake system that can give it an advantage over a competitor.

Think of a brake as input vs. output: you pull the lever at one end and a clamp force is generated at the other end to slow you down. As mentioned above, one of the hallmarks of excellent brake modulation is predictability and if the input doesn't always match the output, you can never put full faith in your brakes' abilities.

Several things can conspire to muddle that signal. For example, a flexy brake caliper can deform when you apply more lever pressure instead of faithfully transferring that command to the rotor or rim. Lever inputs can also be wasted through excess cable and housing friction, improperly bled hydraulic lines, or squishy brake pad materials. Even poor design can be at fault, too, say if the brake lever geometry produces an overly progressive or digressive force at the caliper.

Of course, a skilled rider can largely overcome those issues, but in an ideal world they shouldn't have to.

Why discs and hydraulics are better

I'm not at all going to argue with the notion that rim brakes and conventional braided cables have worked for ages. They're also often very light, easy to service, and highly tuneable. But just because something has always worked doesn't mean it's the best way to do things. After all, there's a reason we don't use lead paint, asbestos, nailed-on cleats, or rotary phones anymore, either.

If you have to pull really hard to get a desired stopping force, you're not able to control your hand effort as well

Let's first address rim brakes. Taken from an outsider's perspective, squeezing a couple of chunks of rubber (or cork) against a rim is flat-out silly, particularly when you consider the exorbitant prices often attached to high-end bikes these days. Likewise, even the best rim brake calipers can be prone to flex with their relatively long expanses of material and multiple pivots.

Advances in pad compounds and rim surface treatments have for sure improved things significantly as have recent forays by Magura and SRAM into the hydraulic rim brake market, but it's still an inherently disadvantaged design.

On the other hand, disc brakes use compact and solidly built forms that are inherently more rigid, plus they're armed with harder pad materials that more effectively transfer clamp force to a dedicated braking surface.

"The braking surfaces are more consistent and the friction material is a lot more sophisticated," says Kantor. "I think the people that make rubber pads for a living would argue that they put a ton of work into it and I'd agree, but we're able to achieve a more complex relationship with a disc brake pad."

Likewise, hydraulic lines take away much of the signal loss that occurs in mechanically actuated brakes due to line friction and housing compression plus they offer a greater mechanical advantage that reduces hand effort.

"Any time you're using less hand effort, you're less likely to spike that lever. If you have to pull really hard to get a desired stopping force, you're not able to control your hand effort as well."

You say I'm overreacting? Think about the fact that you're relying on a few pieces of fancy rubber to control your speed the next time you're bombing a descent at 70km/h and get back to me.

And if there's a reason aside from historical legacy that we're all still willing to accept carbon rims' notoriously poor braking performance in wet weather, for example, I'd sure like to hear it.

What you can do to improve your current situation

While hydraulically actuated disc brakes may offer the best braking performance, the reality is that some riders — roadies in particular — either aren't in a position to easily make the switch or simply aren't prepared to do so for whatever reason, be it weight, compatibility or aesthetics.

Still, there are plenty of things you can do to boost the functioning of your current system.

- Upgrade your cables and housing: Doing a proper installation with clean lines, high-quality bits, and smooth cable paths is the first step and it goes a surprisingly long way. Taken further, you can switch to compressionless housing that will improve lever feel and noticeably improve control.

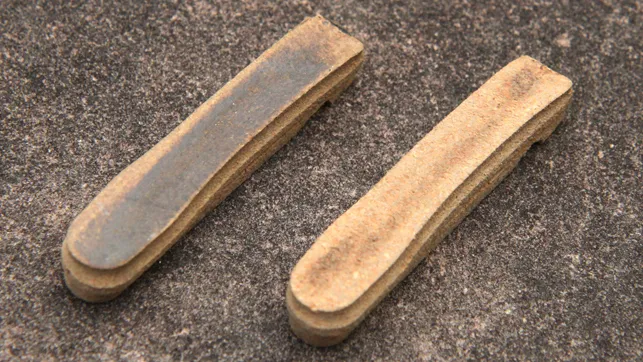

- Tend to your pads and rims: Haven't inspected your rim brake pads or cleaned your rims lately? Try sanding the pads to remove any built-up glaze and use a pick to dig out any embedded aluminum. Use a rag and isopropyl alcohol to clean off the rim sidewalls. Given that any brake relies on friction, it doesn't take much gunk on any of the associated surfaces to screw things up. Disc pads don't require quite the same level of care but they're more sensitive to oil and grease. If they're contaminated, replace them ASAP and clean the rotors before installation.

- Upgrade your brake pads: Stock compounds are generally pretty good but considering the relatively modest cost of premium options, this is another great place to look. For aluminum rims, SwissStop's latest BXP model is nearly impossible to beat and its slightly harder composition can improve lever feel, too. SwissStop is also my go-to choice for carbon rims with its new Black Prince compound, which delivers an impressive amount of bite and great control.

- Lower your tire pressure: Wait, aren't we talking about brakes here? Yes, but as I mentioned earlier, ultimate braking power is still limited by tire traction. Increase the latter and you increase the former by default, plus you automatically give yourself a bigger range of braking control.