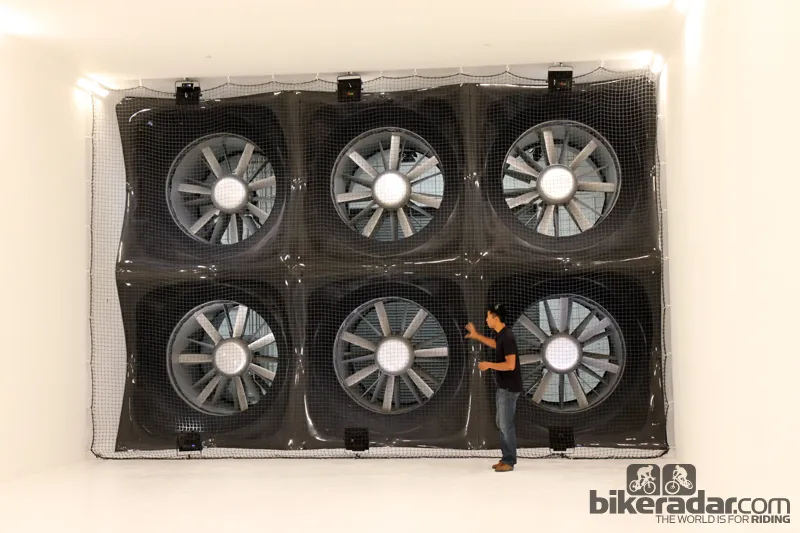

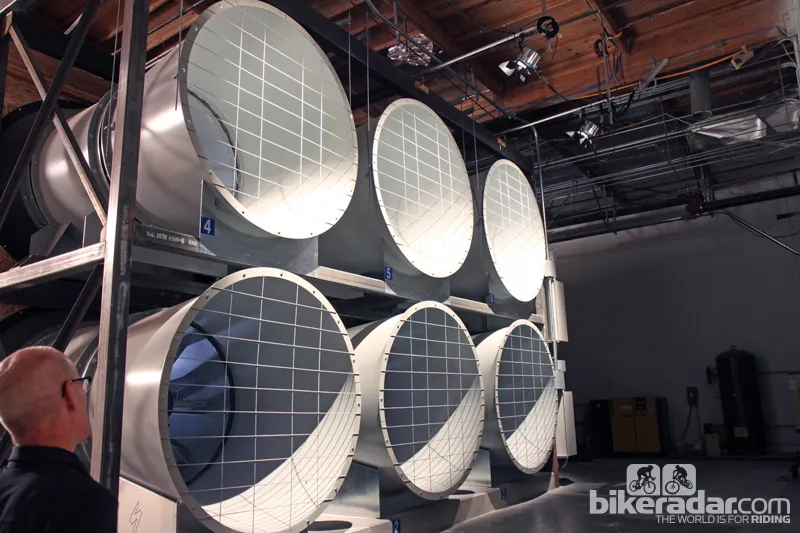

Specialized on Thursday unveiled a wind tunnel the company built at its Morgan Hill, California headquarters. While many companies test and refine product in wind tunnels, having its own wind tunnel designed for cycling (instead of automobiles or aerospace) will allow faster, more in-depth R&D work, according to Specialized.

“This is a bicycle-specific wind tunnel. Everything was built from scratch," said Mark Cote, Specialized's manager of performance road, triathlon and aerodynamics R&D. “This is a fundamental shift in how we think about air; every product and athlete will be faster.”

Combined with the engineering resources inside Specialized, the company can have an idea on Monday and a prototype tested on in the wind tunnel on a Friday, Cote said.

The in-house wind tunnel is an industry first

Cote is part of an aerodynamic design team that also includes Stanford grad Chris Yu, industry veteran Chuck Teixeira and longtime Specialized bike guru Chris D'Aluisio.

“By building and designing a wind tunnel from the ground up, we were able to really concentrate on optimizing the facility for testing human-powered flow regimes; from tuning the air flow and force balance sensitivity to having a comfortable, modern environment to work in,” Yu said.

The wind tunnel is large enough for a small echelon of riders to be tested

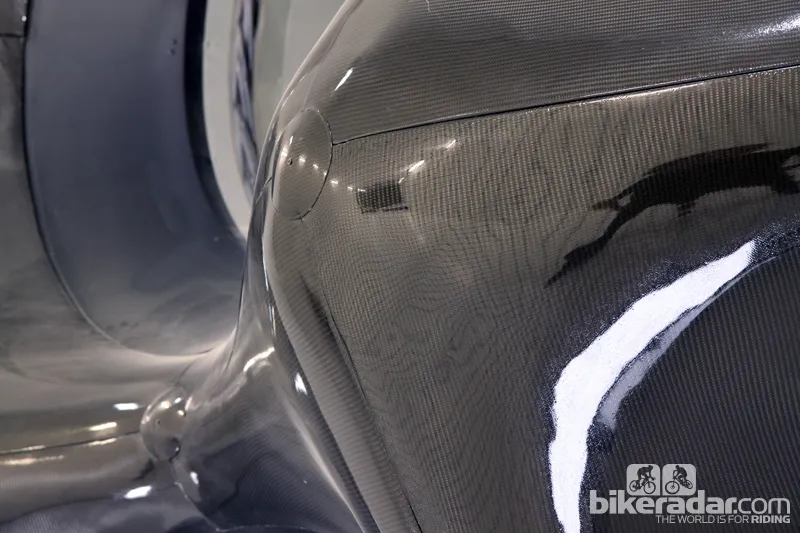

Beyond the Formula 1-type work on high-end race bikes, Specialized can use the wind tunnel for all of its bikes.

"We want to affect aerodynamics on all bicycle categories," Cote said, referring to everything from mountain bikes to commuter bikes.

The wind tunnel is big enough to test multiple riders at the same time, studying how various crosswind angles affect each rider in a group.

Specialized will also use the wind tunnel for its Specialized Bicycle Components University (SBCU) classes for retailers.

Beyond the wind tunnel, Specialized is doing aero testing outside and on velodromes with an on-bike data acquisition system that measures and records wind speed, wind direction, rider power, and even rider positioning. According to Specialized, this not only helps its athletes better understand the impact of aerodynamics in real-time but the collected data is also crucial for developing the mathematical computational fluid dynamics (CFD) models used in the wind tunnel's proprietary software.

"CFD is something that's extremely accurate - if you set it up right," said Yu. "That's the rub."

Specialized is also using an on-bike data acquisition system for real-world aero measurements

The tunnel itself, like any tool, is also only as good as the people using it. And Specialized says it has some of the best in the business, boasting a collective 20,000 hours in wind tunnels. While at MIT, Cote managed the university's wind tunnel there. Yu is currently a PhD student in high-fidelity flow simulation, having done both academic and commercial wind tunnel projects in the past. D'Aluisio played a key role in the design of the Shiv and the Venge, among other bikes at Specialized, while Teixeira's experience with wind tunnels goes back to the 1980s.

"Aero is everything" is the slogan that Specialized keeps repeating around this launch. "Aerodynamics is the largest resistive force that any rider encounters on the road," Cote said. "The only way to make aerodynamics not matter is to completely stop moving."

At Specialized, the aero design team certainly isn't going to stop moving any time soon and the company sees no limitations as to what types of products might benefit from aerodynamic study - everything is fair game. Yu told BikeRadar that downhill racing is the "low hanging fruit" of cycling aerodynamics, though, citing the high speeds, very narrow time gaps, and decidedly non-aerodynamic nature of the equipment currently in use. Recent signing Aaron Gwin was supposedly one of the first Specialized athletes to visit the tunnel so we expect to see some changes in his gear soon.

Specialized has only been operating the tunnel for the past six weeks or so, so there aren't any consumer products on the market that have benefited from its existence. However, whereas renting wind tunnel time currently can easily cost US$10,000 per day, Specialized's in-house tunnel will be far less expensive to operate once you back out the initial investment (and pending solar panel installations on the roof of the building will help, too). More importantly, engineers can test new concepts on a moment's notice with the luxury of not having to pay by the hour.

Given such convenience, only time will tell how much impact it will have from here.

James Huang contributed to this report.

Specialized intends to test a variety of bikes — and gear — in its new tunnel