It’s been one of worst-kept secrets in the world of mountain biking, but SRAM has finally announced its all-new 12-speed single ring mountain bike drivetrains, called XX1 Eagle and X01 Eagle. BikeRadar was there to ride the new groupset and get the full lowdown, so read on for all the specs and tech details and the reasons why we think this news is the beginning of the end for the front derailleur.

If you don’t care about the tech and just want to know how it rides, you can check out our initial impressions of SRAM 12 speed Eagle in our first ride review.

1. It’s got a gear range comparable to many double ring setups

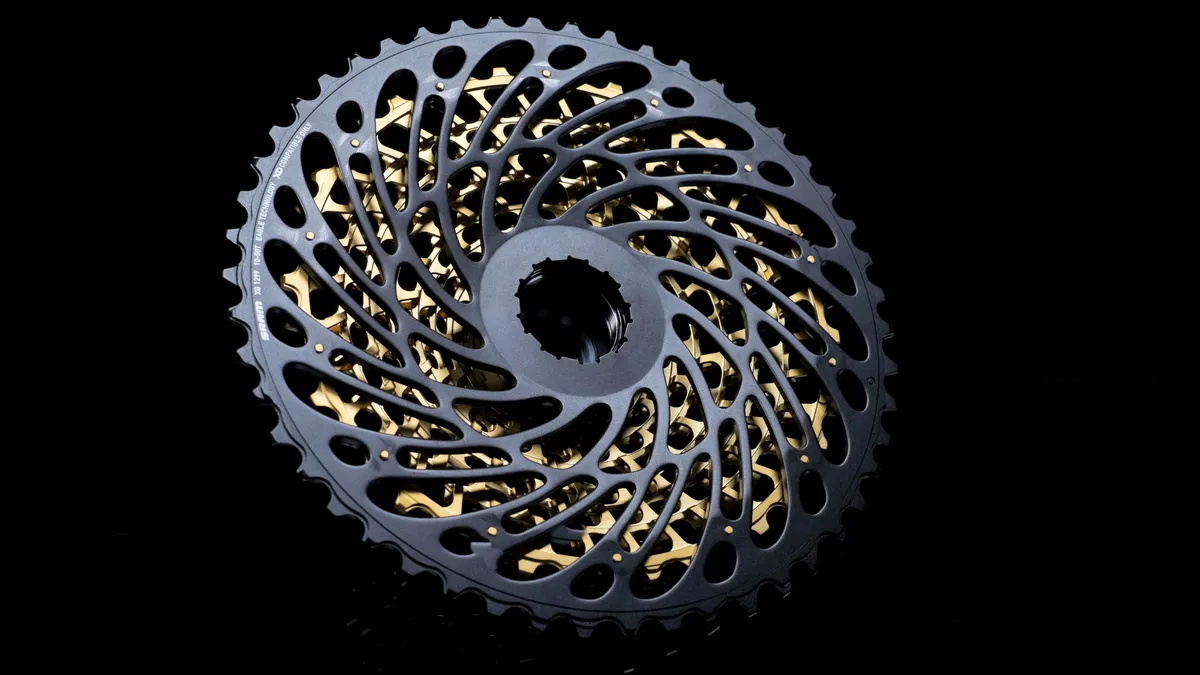

The most obvious change over the outgoing XX1 and X01 groups is that the twelfth sprocket on the cassette is a rather humongous 50t item. That gives you an impressive 500% gear range with a single ring up front. For comparison, Shimano’s new 11-46t cassette only has a 418% range with a single ring setup and a 36/26t double with 11-40t cassette gives a 504% range.

Okay, you could run a Shimano double with the new wider range cassette to get a range up to a staggering 592%, but that doesn’t seem much use unless you regularly pedal up near vertical slopes before cranking it downhill on steep and smooth trails; hardly a common mountain bike riding situation. Front rings are available from 30T-38T, so there's plenty of choice to tune the gearing to your riding needs too.

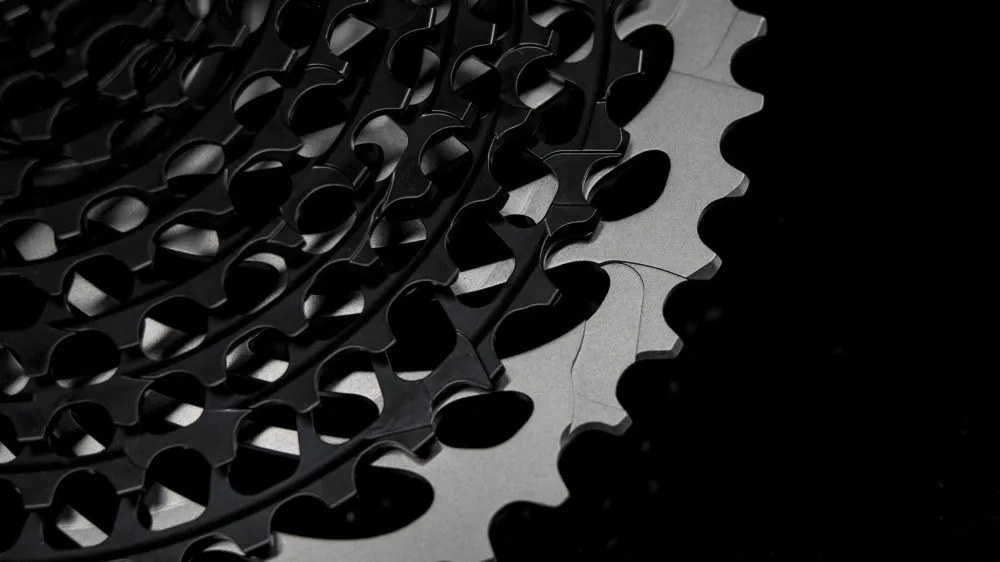

Another smart thing about Eagle is that it uses the same steps between gears as SRAM's existing single ring drivetrains, while the jump from the 42t cog to the new 50t is only 19%. The overall width of the new cassette isn’t far off an 11spd item either, thanks to a slightly narrower chain width and gap between cogs. The 10t cog sits in the same place, while the 50t is slightly more inboard than the largest 42t cog of an 11spd SRAM cassette thanks to a dished profile.

SRAM has worked with a large number of wheel manufacturers to make sure it’ll work with pretty much every wheel on the market today too – if it you can fit an XX1 cassette on there, you can fit an XX1 Eagle item on there. The Eagle cassette is made in the same way as current XX1 and X01 too, with the first 11 cogs being machined from a single piece of high strength steel, with the 50t cog being made from aluminium and riveted to the steel block. The different chain width and spacing does mean that there’s almost no backwards compatibility with SRAM's 11spd groups though – chainring is the only part that will work with an 11spd chain.

It still uses SRAM's existing and widely available XD driver body standard too. Okay, OneUp’s modular cassette for Shimano 11spd can provide the same range but it doesn’t have the same steps between gears and requires a hub compatible with the much less common Mini Driver body if you want a 10t sprocket.

SRAM has managed to add this extra range by tweaking the derailleur slightly too. Yes, the cage is now longer, but it’s no longer than a long-cage Shimano item. The lower jockey wheel has been increased in size from 12t to 14t which helps increase chain capacity, as does having a larger offset on the upper pulley. Interestingly, the upper pulley doesn’t have a narrow-wide tooth profile as SRAM reckons this doesn’t affect shifting in any way.

There’s now a new Type 3 clutch mechanism that provides a higher force but is also smoother. SRAM has toughened up the pivot points with harder materials and the bolt that holds the derailleur to the hanger now allows the derailleur to pivot about it in an IGUS bushing, meaning that the annoying habit of SRAM derailleurs undoing themselves unless tightened down heavily is now unlikely to happen.

2. There’s hardly any weight or price penalty over existing SRAM 11spd drivetrains – and it’s much lighter than any double

Despite taking a huge investment to develop, SRAM has worked hard to keep the price within about 5% of the current XX1 and X01 groups. Okay, at £1,173 / $1,417 / AU$ TBC for the complete XX1 Eagle group and £1,005 / $1,193 / AU$TBC for X01 Eagle, it’s still a high-end product but it’s competitive with what’s on the market at the moment. In fact, when compared with the eye-watering cost of Shimano’s XTR Di2 drivetrain it’s practically a bargain.

There’s only around a 50g weight penalty between comparable 11 and 12spd groupsets, never mind a serious weight advantage over any double setup, so it seems like a bit of a no-brainer to go for the extra cog. The Eagle cassette is actually 60g heavier than the 11spd item, but the weight has been saved elsewhere, most notably in the all-new carbon crankset, which SRAM says is stiffer and lighter than before.

SRAM’s previous top-end carbon crankset used the same construction whether it was branded as XX1 for cross-country racing or X01DH for World Cup downhilling. Instead, the XX1 Eagle is made to be as light as possible with a hollow carbon construction, tipping the scales at 465g.

X01 Eagle is designed to be a bit tougher, especially when it comes to pedal impacts, using the same carbon construction but with a foam core. It’s a bit heavier at 495g. This also highlights that SRAM feels the XX1 group should be the choice for cross-country racers and lightweight trail use, while X01 is aimed at harder trail riding and enduro racing.

The cranksets are available in either 170mm or 175mm lengths, and you can take you pick from 24mm GXP or 30mm axles, both available as standard or Boost spacings.

XX1 Eagle also gets more carbon in certain areas such as the derailleur cage and shifter cover and lever, giving it a total claimed weight (minus bottom bracket) of 1456g vs 1502g for X01 Eagle.

In fact, while SRAM will continue to support those who want XX1 and X01 11spd, brand reps say that most product managers they’ve spoken to have been much keener to spec Eagle instead of the old high-level groups.

3. SRAM says it’s going to be much longer lasting

First up, not having to shunt the chain over front chainrings naturally puts less stress on it, but SRAM says the Eagle groups are even better than its existing 1x 11spd systems. Okay, we won’t know the truth behind this claim until we’ve had some serious testing time on the drivetrain, but SRAM has spent an awful lot of time and money on improving durability in ways that aren’t immediately apparent.

Take the chain for example. There are now 31 steps in the stamping process that creates the inner and outer links. That means they’re flatter and the edges are more smoothly chamfered, both reducing the chances of a weak link by making riveting more consistent and also ensuring smoother shifting, less noise and less wear. It also means the chain works better at the more extreme angles such a wide range design requires. SRAM even had to develop a new heat-treating process to make the new, stronger steel used in the chain harder than ever. The brand claims that the new chain adds three to four times to the life of a chainring.

While the widest part of a normal chain is the pins, in order to fit more cogs into a space that’s only slightly wider than an 11spd block they’re now totally flush. While that might sound simple enough, it gave SRAM’s engineers a huge headache in order to do this and ensure that the chain is as durable as ever, involving building an all-new assembly line with special tooling. We weren’t given exact numbers, but SRAM said it was a very significant investment. Both the XX1 and X01 chains also get a super hard titanium nitride coating to reduce friction and improve lifespan too, with the same coating applied to the XX1 cassette too.

If you look closely at the narrow-wide chainring, you’ll notice that the tooth profile is now totally different. While SRAM created the X-Sync narrow-wide design, it readily admits it was a leap into the unknown. In the four years since that first design, a lot hs been learned. One of the big goals of the Eagle project wasn’t just to extend range and add a cog, it was to improve all aspects of how SRAM's drivetrain worked and the new X-Sync 2 is a great example of this.

The teeth are stepped and chamfered in a much more detailed way. The main aim behind this was to helps spread the chain load more evenly around the chainring, rather than it being concentrated on the first two or three teeth that engage with the chain. SRAM says that doing this makes it more durable, efficient and quieter, while chain rentention is improved too.

4. It’s going to revolutionise bike design

While many bike manufacturers have got on board with designing bikes that can only use a 1x setup, others have been hedging their bets, knowing that in many markets riders still prefer being able to run a double. Now SRAM has come very close to equalling that kind of gear spread, it’s highly likely we’ll see a lot more bikes designed to be single ring specific from the outset. That means more space to widen pivots in order to increase stiffness or the ability to have shorter chainstays and better mud clearance. Not having to create any extra mounts also helps shave a few grams.

It will also help improve suspension performance too. If you have multiple chainrings up front, pivot placement is always going to be a compromise to balance how the chain tension and geometry will affect suspension movement – known as anti-squat – in the different rings. If designers can create their suspension around a chainring size suited to the application, they don’t need to hedge their bets and can tune the suspension to perform just how they want it to.

5. It’s eventually going to trickle down to affordable bikes

If history has told us anything, it’s that in time, top end technology eventually becomes affordable to the masses. Of course, that’s not going to happen overnight, but when it eventually does happen, it’ll be a great thing for beginner riders as well as more seasoned shredders. Having two shifters is always going to be harder to get your head around than just a single one – imagine learning to drive a car with two gearshift levers.

The easier it is to get your head around riding a bike, the more likely you are to keep wanting to do it, which means our sport will grow. If the thought of spreading the joy of riding bikes with more people doesn’t make you feel warm inside, think about this: when there are more riders, manufacturers will have ever greater economies of scale, allowing them to produce better quality equipment at lower prices.

Do you agree with us that the front derailleur’s days are numbered? Let us know what you think in the comments below or on Facebook.